Product Overview

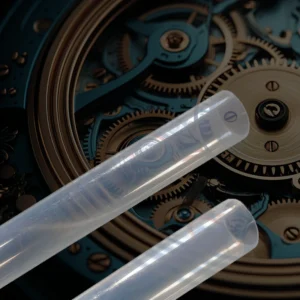

Unlock unparalleled protection with Teflon X’s PFA Shrink Tube, featuring ultra-transparent PFA construction for exceptional chemical and heat resistance in the most critical applications. Our PFA Shrink Tube delivers unmatched dielectric strength to safeguard sensitive electronics in laboratories and power plants, while its inherent flexibility accommodates irregular shapes for a seamless fit. The non-stick surface of this PFA Shrink Tube resists industrial contaminants, ensuring longevity and ease of maintenance in demanding environments. With a robust temperature range from -200°C to 260°C, Teflon X’s PFA Shrink Tube is trusted for aerospace and semiconductor manufacturing, where high clarity and reliability are non-negotiable.

Teflon X leads in fluoropolymer solutions, providing PFA Shrink Tube that combines transparency, durability, and performance. Explore our offerings at https://teflonx.com/, or contact us through the Contact Us page or email Allison.Ye@teflonx.com for expert support on PFA Shrink Tube integration.

Key Features

- Ultra-Transparent Clarity: Superior optical transparency in PFA Shrink Tube enables precise visual inspection of enclosed components without disassembly.

- Exceptional Chemical Resistance: Virtually impervious to acids, bases, solvents, and aggressive chemicals, making PFA Shrink Tube ideal for corrosive industrial settings.

- High Heat Resistance: Continuous operation from -200°C to +260°C, with short-term exposure up to 300°C, for reliable PFA Shrink Tube performance in extreme thermal conditions.

- High Dielectric Strength: Provides outstanding electrical insulation to protect sensitive electronics within PFA Shrink Tube applications.

- Flexible and Conforming Design: Easily adapts to irregular shapes with a 2:1 shrink ratio, ensuring a tight seal in versatile PFA Shrink Tube uses.

- Non-Stick, Low-Friction Surface: Prevents contaminant adhesion and simplifies cleaning, a key advantage of our PFA Shrink Tube.

- UV and Abrasion Resistance: Maintains structural integrity and clarity in outdoor or high-wear environments for durable PFA Shrink Tube installations.

- Flame Retardant and High Purity: Meets UL standards with low leach-out, suitable for cleanroom and high-purity PFA Shrink Tube requirements.

- Mechanical Durability: High tensile strength and elongation ensure PFA Shrink Tube withstands mechanical stresses without cracking.

Technical Specifications

Teflon X’s PFA Shrink Tube is engineered to the highest standards for precision and reliability. Below is a detailed table of key parameters:

| Parameter | Specification | Notes |

|---|---|---|

| Material | Perfluoroalkoxy (PFA) | Fluoropolymer for superior performance |

| Color | Clear/Transparent | High optical clarity for visual inspection |

| Shrink Ratio | 2:1 | Expands to fit over components, shrinks to 50% of original diameter |

| Operating Temperature | -200°C to +260°C (continuous) | Short-term up to +300°C; suitable for cryogenic to high-heat uses |

| Shrink Temperature | 150°C – 200°C | Quick recovery with standard heat sources like hot air guns |

| Dielectric Strength | >15 kV/mm | Excellent insulation for high-voltage applications |

| Tensile Strength | ≥25 MPa | High mechanical durability |

| Elongation at Break | ≥300% | Flexible and resistant to cracking |

| Hardness (Shore D) | 55 – 65 | Balances flexibility with rigidity |

| Specific Gravity | 2.15 g/cm³ | Lightweight yet robust |

| Flammability | UL 224 VW-1 | Self-extinguishing, low smoke generation |

| Standard Sizes (ID) | 1.0 mm – 50 mm | Custom sizes available upon request |

| Wall Thickness (Recovered) | 0.2 mm – 2.0 mm | Thin walls for space-constrained designs |

Note: Specifications are based on standard testing methods (e.g., ASTM D2671). For exact values tailored to your application, contact Teflon X.

Applications

Teflon X’s PFA Shrink Tube excels in high-tech and industrial sectors requiring precision and resilience:

- Aerospace and Semiconductor Manufacturing: Insulates wiring and components with ultra-transparent PFA Shrink Tube for contamination-free, heat-resistant protection.

- Laboratories and Power Plants: Shields sensitive electronics from chemicals and thermal extremes using reliable PFA Shrink Tube.

- Chemical Processing: Lines pipes and valves with chemically inert PFA Shrink Tube to handle aggressive media without degradation.

- Electronics and Medical Devices: High-purity PFA Shrink Tube ensures electrical safety and easy inspection in sterile environments.

- HVAC and Industrial Machinery: Flexible PFA Shrink Tube accommodates irregular shapes while resisting contaminants in operational systems.

Our PFA Shrink Tube complies with UL, RoHS, and SEMI F-57 standards, facilitating integration into regulated industries.

Why Choose Teflon X’s PFA Shrink Tube?

Teflon X’s PFA Shrink Tube sets the benchmark with its ultra-transparent design, superior chemical and heat resistance, and non-stick versatility, drawing on decades of fluoropolymer innovation. ISO-certified manufacturing guarantees consistent quality for aerospace, labs, and beyond. Choose PFA Shrink Tube that outperforms—contact Allison.Ye@teflonx.com or visit https://teflonx.com/contact-us/ for samples, custom sizing, or technical consultations.

Reviews

There are no reviews yet.