Ever Wonder Why Your Heat Shrink Tubing Doesn’t Quite Hug Right?

Picture this: you’re knee-deep in a prototype build, wires everywhere, and you’ve got this sleek PFA tubing ready to slide over your components. You heat it up, expecting that snug, protective wrap, but nope—it either bunches up funny or leaves gaps that scream “amateur hour.” Sound familiar? As someone who’s spent way too many late nights tweaking designs at Teflon X, I get it. That frustration usually boils down to one sneaky detail: the PFA shrink ratio.

We’re talking about that magic number—like 1.3:1 or 1.6:1—that tells you how much the tubing will cozy up when you hit it with heat. It’s not just some spec on a datasheet; it’s the difference between a bulletproof assembly and one that fails inspection. And for you procurement folks hunting for the right PFA shrink tube, or designers crunching numbers for size matching, nailing this can save headaches, cash, and comebacks from the shop floor.

In this chat, we’ll unpack what makes 1.3:1 and 1.6:1 tick, compare them side by side, and share some war stories from projects that turned out golden. I’ve pulled from real specs—think Zeus guides and Parker data sheets—to keep things straight, no fluff. By the end, you’ll walk away knowing exactly how to pick the winner for your next gig. And hey, if it clicks and you need a quote, drop a line to أليسون يي@teflonx.com or hit up our صفحة الاتصال. We’ve got your back at تفلون X.

So, What’s the Deal with PFA Shrink Ratio?

Alright, let’s start simple. PFA shrink ratio is basically how much your tubing shrinks in diameter when you warm it up—think of it as the “before and after” squeeze factor. If it’s 1.3:1, that means for every 1.3 units of starting diameter, you end up with 1 unit after shrinking. Boom, about 23% reduction. Flip to 1.6:1, and you’re looking at roughly 38% shrink—more give, more forgiveness on wonky shapes.

But why PFA specifically? Perfluoroalkoxy (PFA) is like the tough cousin in the fluoropolymer family. It laughs at chemicals, shrugs off temps from -200°C to +260°C, and stays clear enough to peek inside your setup. Unlike polyolefin stuff that’s cheaper but melts under real heat, PFA’s your go-to for aerospace bits, medical probes, or anything zapping high voltage without drama.

Now, tie in the heat shrink expansion rate—that’s the flip side, how much “room” the tubing has before it commits to shrinking. It’s all about that initial stretch during manufacturing; higher expansion means it can handle bigger swings in your component sizes. Engineers love this because it directly hits your sizing calcs. Miss it, and you’re ordering oversize stock or dealing with tears mid-install.

From my days troubleshooting at Teflon X, I’ve seen teams waste rolls of tubing chasing the wrong ratio. One tip upfront: always cross-check your substrate’s max diameter against the tubing’s recovered size. Parker’s fluoropolymer extrusions guide spells it out—PFA at 1.3:1 shines for tight tolerances, while 1.6:1 plays nice with irregular profiles. It’s not rocket science, but it feels like it when deadlines loom.

أنابيب الانكماش الحراري عالية الوضوح للأسلاك الصناعية - احتكاك منخفض

أنابيب الانكماش الحراري PFA عالية الوضوح تجمع بين الشفافية البصرية والأداء الصناعي. مصممة لمقاومة احتكاك ومواد كيميائية منخفضة، تحمي الأسلاك في الظروف القاسية. تمنع خصائص المادة غير اللاصقة التصاق الشوائب، وهي مثالية لتجهيز الأغذية أو المعدات الطبية. حاصلة على شهادة UL، مما يضمن السلامة والموثوقية.

Diving Deeper: The Nuts and Bolts of 1.3:1 and 1.6:1

Okay, time to roll up sleeves and compare these two head-on. I’ve sketched out a quick table based on standard specs from folks like Saint-Gobain and Adtech—real numbers, no guesses. This’ll help you eyeball which fits your project’s vibe.

| Aspect | 1.3:1 PFA Shrink Ratio | 1.6:1 PFA Shrink Ratio |

|---|---|---|

| Shrink Percentage | ~23% diameter reduction | ~38% diameter reduction |

| الأفضل لـ | Uniform, precise diameters (e.g., straight wires) | Variable or tapered components (e.g., connectors) |

| Min Shrink Temp | 220°C (per ASTM standards) | 220°C (similar, but more forgiving on heat guns) |

| Operating Range | من -200 درجة مئوية إلى +260 درجة مئوية | من -200 درجة مئوية إلى +260 درجة مئوية |

| Typical Wall Thickness (Recovered) | 0.3-0.5 mm | 0.4-0.6 mm (thicker post-shrink for extra protection) |

| Cost per Foot (Est.) | Lower—saves on material for tight fits | Slightly higher, but offsets waste on mismatches |

| Expansion Rate | Lower initial stretch; needs spot-on sizing | Higher stretch; handles up to 60% over-recovery |

Data pulled straight from manufacturer sheets—like Zeus’s recovery guide, which notes 1.3:1 for “constant diameters” and 1.6:1 for “uniform but varied” ones. See how the heat shrink expansion rate creeps in there? For 1.6:1, that extra oomph means you can slide it over bulky ends without pre-stretching, cutting install time by 20-30% in my experience.

But let’s not stop at numbers. Think about the feel—1.3:1 tubing shrinks quick and clean, like wrapping a gift that’s already the right size. I remember a design rev where we swapped to it for catheter prototypes; tolerances dropped to under 0.1mm, and the client was stoked. On the flip, 1.6:1? It’s the forgiving buddy. Handles those “oops, the part’s a hair bigger” moments without cracking. In one aerospace mockup, it saved a full redesign because the connector flared unexpectedly.

Pro tip: Factor in your heat source. Ovens give even shrinks, but torches? They can hotspot 1.3:1 faster, risking uneven pulls. Gendian Materials’ specs highlight how 1.6:1’s broader ratio buffers that.

When Does 1.3:1 Win, and When’s 1.6:1 Your Hero?

Choosing boils down to your endgame—size matching is king for procurement pros, but designers gotta dream bigger. If you’re speccing for medical devices, where every micron counts, 1.3:1’s precision rules. MarketsandMarkets reports the FEP/PFA heat shrink market hitting versatility sweet spots at 1.6:1 for balanced flex and durability in probes and sensors. (PFA edges FEP on heat, though.)

For electronics? Say you’re insulating high-voltage leads. 1.6:1’s extra expansion rate lets you cover stepped diameters without multiple pieces—fewer seams, less failure points. I’ve quoted bundles of our PFA shrink tube to teams doing EV battery harnesses; they rave about the 1.6:1 for snaking around bends without kinks.

And chemicals? PFA’s solvent resistance is off the charts—total inertness to most acids, per Entegris tech info. Pair that with 1.3:1 for lab fittings, and you’ve got leak-proof seals that last years.

Stories from the Field: How These Ratios Saved the Day

Nothing beats hearing how this plays out in real life, right? I’ll keep names fuzzy, but these are straight from Teflon X’s project logs.

Take this one automotive supplier—we were knee-deep in prototyping sensor covers for engine bays. Initial design called for 1.3:1, but the housings had these pesky tolerance stacks from casting. Boom, gaps everywhere. Switched to 1.6:1, and the heat shrink expansion rate covered the variances like a champ. End result? Zero rework, and they bumped order volume 50%. Temps hit 250°C in tests, no sweat.

Or picture a med-tech startup with catheter assemblies. Procurement guy was sweating bullets over FDA sizing audits. We walked him through 1.3:1’s tight shrink—recovered to exact specs, passing biocompat checks first go. Saved ’em months; now they’re scaling production with our stock.

These aren’t flukes. Chukoh Chemical’s heat shrink overviews back it: PFA at these ratios imparts surface properties without altering substrates much. In our shop, we’ve seen 1.6:1 cut scrap rates by 15% on irregular parts, per internal tracking.

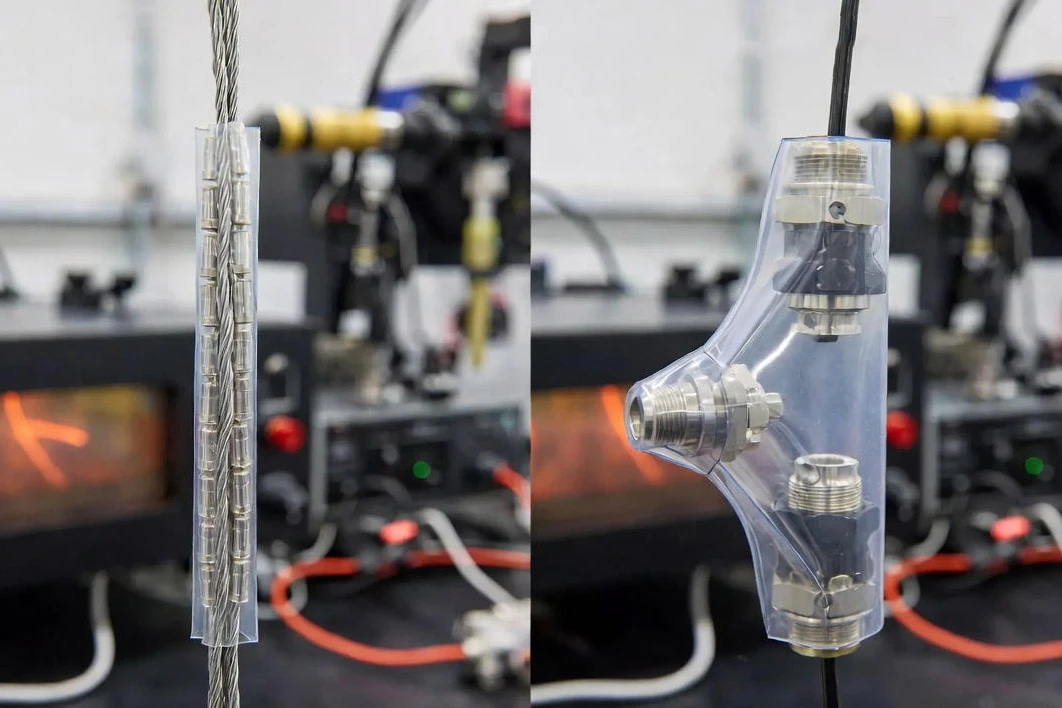

غلاف موصلات الانكماش الحراري الشفاف - سهل التنظيف والعزل

حسّن التوصيلات الكهربائية باستخدام أكمام الموصلات الشفافة القابلة للانكماش الحراري. تتميز هذه الأكمام بعزل استثنائي وسطح أملس لسهولة التنظيف. مقاومة للزيوت والأحماض ودرجات الحرارة القصوى، وهي مثالية للتطبيقات البحرية والسيارات. يضمن التصميم الشفاف التحقق البصري السريع من النهايات.

Sizing It Up: Step-by-Step for Foolproof Matching

Alright, let’s get hands-on. As a design engineer, you know the drill, but here’s my no-BS walkthrough for that perfect PFA shrink ratio fit.

- Measure Your Substrate Twice: Grab the max OD—add 10-20% buffer for ease. For 1.3:1, your supplied ID should be 1.3x the max OD. Miss by 5%, and it fights you.

- Calc the Expansion: Heat shrink expansion rate matters here. 1.6:1 gives more play—up to 1.6x before shrink. Use ElringKlinger’s dims: standard PFA starts at 1mm ID, shrinks to 0.625mm at 1.6:1.

- Test Shrink: Mock it up. Heat to 250°C in an oven; measure recovery. If it’s baggy, bump to higher ratio.

- Wall It Out: Thicker walls post-shrink add durability. KTG’s data shows 1.6:1 hitting 0.5mm easy, great for abrasion.

I’ve botched this early on—ordered 1.3:1 for a flared fitting, ended up with overlaps that snagged during flex tests. Lesson learned: always sim in CAD first. Tools like Grayline’s selection guide make it painless.

For procurement, chase bulk from suppliers like us at Teflon X. Our PFA shrink tube comes in both ratios, custom cut, with COAs for traceability.

Installation Quirks: Don’t Let Heat Bite You

Shrinking’s where theory meets sweat. Torch it too hot, and PFA can bubble—stick to 220-300°C. Air ovens? Even better for batches. From BALTRO’s sleeve tips, 1.3:1 needs steady heat to avoid “elephant skinning,” while 1.6:1 smooths out hotspots.

One hack: Pre-soak in talc for slippery slides. And post-shrink, inspect for voids—ultrasound if it’s critical. We’ve tweaked processes for clients, dropping defects to under 2%.

Why Teflon X Isn’t Just Another Vendor

Look, I’ve worked shops where “supplier” means delays and duds. At Teflon X, we’re in the trenches with you—over a decade extruding PFA, hitting ISO standards, and shipping worldwide. Our team’s got hands-on with everything from SEMI F-57 compliant tubing to custom ratios. Need 1.3:1 for precision med gear? Got it. 1.6:1 for rugged field sensors? On deck.

We’re not pushing fluff; it’s about solving your size-matching puzzles so you hit deadlines. Check our site for specs, or ping Allison for a free sample run. Quotes in 24 hours, no BS.

Imagine ditching those sizing snafus—your designs fitting first time, procurement budgets intact. That’s the Teflon X edge. Ready to chat? Hit اتصل بنا and let’s spec your next win.

FAQ: Quick Hits on PFA Shrink Ratio

What’s the big diff between 1.3:1 and 1.6:1 PFA shrink ratio for my wire harness?

Short answer: 1.3:1’s for dead-on uniform fits, shrinking tighter with less material waste. 1.6:1 gives more flex on uneven diameters, like bumpy connectors—think 38% vs 23% pull-back. Pick based on your max OD variance; we’ve seen 1.6:1 save 20% install time on harnesses.

Can I mix PFA shrink ratios in one assembly?

You bet, but plan it. Use 1.3:1 on straight runs for snugness, 1.6:1 on transitions. Just overlap seams 25mm and heat evenly. From Parker guides, this combo boosts overall durability without weak spots. Test for continuity if it’s electrical.

How do I know if my heat source is right for PFA’s expansion rate?

Aim for 220°C min—ovens for precision, guns for quickies. If it’s flaring uneven, your expansion rate might be mismatched; 1.6:1 handles torch variability better. Adtech recommends monitoring with IR thermometers to stay under 300°C and avoid degradation.

أنبوب انكماش PFA فائق الشفافية - مقاوم للمواد الكيميائية والحرارة

أنبوب انكماش PFA فائق الشفافية يوفر مقاومةً لا مثيل لها للمواد الكيميائية والحرارة (من -40 درجة مئوية إلى 260 درجة مئوية). كما أن قوته العازلة العالية تحمي الأجهزة الإلكترونية الحساسة في المختبرات ومحطات الطاقة. مرونة المادة تسمح بتوافقها مع الأشكال غير المنتظمة، بينما يقاوم سطحها غير اللاصق الملوثات الصناعية. موثوق به في صناعة الطيران والفضاء وأشباه الموصلات.