If you’re a production manager dealing with flammable liquids day in and day out, you know how quickly things can go wrong. One little spark from static buildup, and suddenly you’re facing a fire or worse. I’ve seen it happen more times than I’d like in plants just like yours – transferring solvents, fuels, or chemicals through regular hoses that don’t handle static properly. That’s where conductive PTFE hoses come in. They’re not some fancy add-on; they’re a straightforward way to cut down on those electrostatic discharge hazards that keep you up at night.

Think about it: when you’re pumping flammable stuff, friction inside the hose builds up charge. If it doesn’t have a way to dissipate safely, bam – spark, ignition, chaos. Conductive PTFE hoses, like our Anti-Static PTFE Braided Hose at Teflon X, have a special liner that lets that charge flow out harmlessly, usually through grounding to the braid and fittings.

Understanding Electrostatic Discharge Hazards in Flammable Transfer

So, what’s the big deal with static in the first place? When liquids flow through a hose, especially non-conductive ones, charge separates and accumulates. In flammable transfer, this can lead to sparks energetic enough to ignite vapors.

Real-world stats back this up. According to reports from the U.S. Chemical Safety Board (CSB), static sparks have caused major incidents, like the 2007 and 2008 explosions at Barton Solvents facilities during flammable liquid transfers. In one case, inadequate bonding and grounding let static build up, igniting vapors and causing massive fires. NFPA 77, the Recommended Practice on Static Electricity, highlights how common this is in industries handling solvents and fuels.

OSHA guidelines under 29 CFR 1910.106 also stress preventing ignition from static during flammable liquid handling. They’ve cited cases where poor hose choices contributed to risks.

Common Sources of Static Buildup

Here’s a quick table breaking down where static often comes from in transfer ops:

| Source | How It Happens | Risk Level in Flammable Transfer |

|---|---|---|

| High-flow pumping | Turbulence in liquid | High |

| Splash filling | Air mixing with liquid | Very High |

| Non-conductive hoses | Charge can’t dissipate | High |

| Filters or narrow lines | Increased friction | Medium to High |

| Two-phase flow (liquid/gas) | Bubbling and agitation | High |

Using an explosion proof hose or fuel transfer hose designed for static control flips this around.

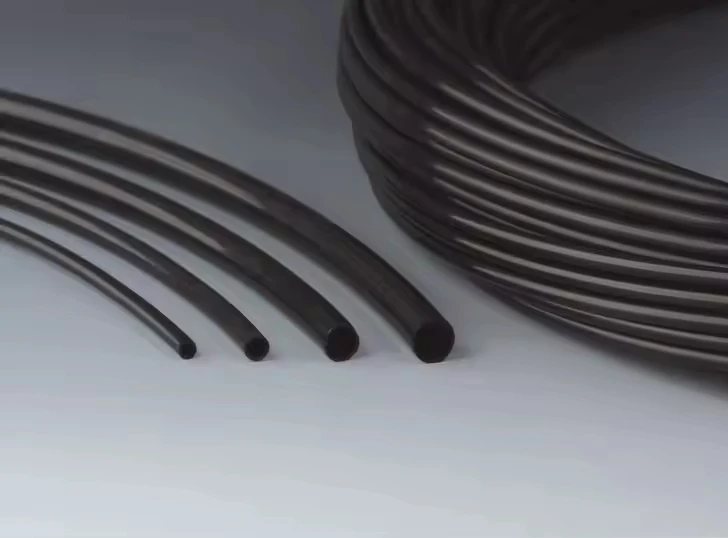

Anti-Static PTFE Braided Hose – Flexible Gas Line with Stainless Steel Braid

Our anti-static PTFE braided hose is ideal for flexible gas line applications. Reinforced with stainless steel, this braided fuel line ensures durability and safety. The conductive braided tube dissipates static electricity, perfect for hazardous environments. It’s the perfect stainless steel braided teflon hose option.

Why Regular Hoses Fall Short – And How Conductive PTFE Steps Up

Standard PTFE hoses are great for chemical resistance – they handle aggressive stuff without breaking down. But they’re insulators, so static just sits there building up. That’s fine for non-flammable apps, but in fuel transfer or solvent lines? Not so much.

Conductive versions add carbon black or similar to the liner, making it dissipative. Charge flows to the stainless steel braid and out through proper grounding. No pinholes from arcing, no sudden sparks.

I’ve worked with plants where switching to these cut near-misses way down. One chemical facility I consulted for (keeping it anonymous, of course) was transferring toluene blends. They had a couple close calls with sparks from old hoses. Swapped to conductive PTFE, grounded everything right, and problems vanished. Safer crew, smoother ops.

Key Benefits of Conductive PTFE Hoses

- Static Dissipation: Safely bleeds off charge, reducing electrostatic discharge hazards.

- Chemical Compatibility: Resists almost everything, from acids to solvents.

- Temperature Range: Handles extremes, often -70°C to +260°C.

- Flexibility and Durability: Braided stainless steel outer means it bends without kinking, lasts longer.

- Compliance: Meets standards like ISO 8031 for conductivity in hazardous spots.

Compared to rubber or plain plastic hoses, these are tougher and safer for explosion proof hose needs.

Real-Life Applications and Success Stories

In paint manufacturing, flammable solvents get pumped constantly. One mid-sized plant had recurring static issues with their fuel transfer hose setup. Sparks were jumping, scaring operators. They upgraded to anti-static braided PTFE lines, added bonding clips, and followed NFPA 77 grounding recs. No incidents since, and production uptime improved because less downtime for checks.

Another scenario: pharma plants handling acetone or ethanol. These low-conductivity liquids charge up fast. Conductive hoses prevent that buildup, keeping things explosion-proof.

Or think fuel depots – diesel, gasoline transfers. A proper fuel transfer hose with conductive liner avoids the risks seen in those CSB reports.

At Teflon X, we’ve supplied these to various ops, and feedback’s always about peace of mind. Our Anti-Static PTFE Braided Hose is built exactly for this, with flexible gas line capabilities too.

Best Practices for Safe Flammable Transfer

To get the most from conductive PTFE hoses:

- Always ground and bond – connect hose ends to verified earth points.

- Avoid splash filling; bottom-load if possible.

- Keep flow velocities reasonable – too fast ramps up charge.

- Inspect regularly for wear; damaged braid loses conductivity.

- Use in combo with other controls, like inerting or ventilation.

Corrugated Flexible Hose – PTFE Teflon Pipe for Medical Use

Corrugated flexible hoses made of PTFE from Teflon X are perfect for medical equipment and chemical processing with zero friction. These ptfe hoses offer a smooth inner wall for optimal fluid discharge and hygiene. Built with spiral steel wire, this black plastic corrugated pipe resists kinking and supports custom sizing.

Comparison Table: Hose Types for Flammable Apps

| Hose Type | Static Control | Chemical Resistance | Best For | Drawbacks |

|---|---|---|---|---|

| Standard Rubber | Poor | Medium | General liquids | Wears fast, not for extremes |

| Plain PTFE | None | Excellent | Corrosives, non-flammable | Static buildup risk |

| Conductive PTFE Braided | Excellent | Excellent | Flammable transfer, solvents | Slightly higher cost |

| Metal Hoses | Good (if grounded) | Good | High pressure | Less flexible |

Clearly, for your needs as a production manager, conductive PTFE wins on safety.

Standards and Why They Matter

NFPA 77 recommends static control for flammable handling, including dissipative hoses. OSHA requires precautions against ignition sources like static. In hazardous locations, ATEX or similar directives often mandate conductive materials.

Choosing hoses that meet these isn’t just checking boxes – it’s protecting your team and facility.

FAQs About Conductive PTFE Hoses in Industrial Safety

What makes a hose “explosion proof” for flammable transfer?

It’s not fully explosion-proof on its own, but conductive liners prevent static sparks – a common ignition source. Pair with grounding for best results.

How do I know if my fuel transfer hose needs to be conductive?

If handling low-conductivity flammables like solvents or fuels, yes. Check flow rates and if vapors can form explosive mixes.

Can static buildup really cause explosions in factories?

Absolutely – CSB investigations show it happening during simple transfers without proper controls. Dissipative hoses help avoid that.

What’s the difference between anti-static and conductive hoses?

Anti-static reduces buildup; fully conductive (like carbon-lined PTFE) dissipates it fastest, ideal for hazardous spots.

How often should I replace conductive PTFE hoses?

Depends on use, but inspect monthly. Look for braid damage or stiffness. Quality ones last years with care.

If you’re dealing with these risks, it’s worth chatting about your setup. At Teflon X, we help folks like you find the right solutions. Drop us a line at Allison.Ye@teflonx.com or head to our contact page for a quote on conductive PTFE options. Better safe than sorry, right? Let’s keep your plant running smooth and hazard-free.

Flexible PTFE Inner Flat Outer Corrugated Tubing for Food Processing

Our Flexible PTFE Inner Flat Outer Corrugated Tubing is designed with a smooth inner layer for easy cleaning and a corrugated outer for flexibility in food processing lines. This Inner Smooth Bore Outer Corrugated PTFE Tube ensures FDA-compliant, non-toxic transfer of edibles and beverages.

Perfect for conveying viscous materials, the PTFE Bellows Tube variant prevents flavor contamination and withstands frequent washdowns.

Incorporate this Internal Flat External Wave Corrugated Pipe into your setup; its PTFE Inner Flat Outer Corrugated Tubing structure guarantees hygiene and durability.