Ever stared at a pile of vacuum hoses in the warehouse, wondering which one’s gonna hold up when things get brutal? You know, that moment when you’re knee-deep in a project, sucking up abrasive grit or pulling a vacuum so strong it could yank the fillings from your teeth, and the hose just… gives out. Crushes, kinks, or worse, leaks like a sieve. I’ve been there, trust me—years slinging hoses in shops from auto repair bays to chemical plants, and picking the right one isn’t just about specs on paper. It’s about what keeps your operation humming without a hitch.

I’m talking real talk here, not some glossy brochure fluff. As someone who’s wrestled with these beasts firsthand at Teflon X, I’ve seen what works and what leaves you cursing under your breath. We’re diving into heavy wall vs. wire reinforced vacuum hose today, zeroing in on that vacuum resistance reinforcement you need for high-stakes jobs. We’ll unpack the pros, the quirks, and yeah, even throw in some war stories to show why one might edge out the other for your setup. By the end, you’ll have the guts to make a call that saves time, cash, and headaches. Let’s roll.

What’s the Big Fuss About Vacuum Hoses?

Picture this: you’re running a vacuum line in a dusty mill, or maybe transferring volatile stuff in a lab where one wrong flex means downtime. Vacuum hoses aren’t just tubes—they’re your frontline defense against collapse under pressure (or lack thereof). The core job? Handle negative pressure without folding like a cheap lawn chair.

Most folks jump straight to “stronger is better,” but it’s more nuanced. Heavy wall hoses pack extra thickness for brute strength, while wire reinforced ones, like those with a steel wire helix hose weave, add that spiral backbone to fight kinking. Both aim for solid vacuum resistance reinforcement, but they shine in different spots. According to ASTM F450-09 standards, which test how hoses take everyday abuse like bending and pulling, the right pick can mean lasting 10 times longer under vacuum loads. No joke—that’s the diff between a hose that quits after a season and one that becomes your shop’s old reliable.

Why care now? Industries are pushing harder vacuums for efficiency—think 25-29 inches of mercury (inHg) for heavy-duty pulls—and subpar hoses lead to 20-30% more failures in abrasive setups, per industry reports from hose pros. If you’re the decision-maker eyeing high-strength vacuum hoses, getting this wrong costs real dough in replacements and lost runs.

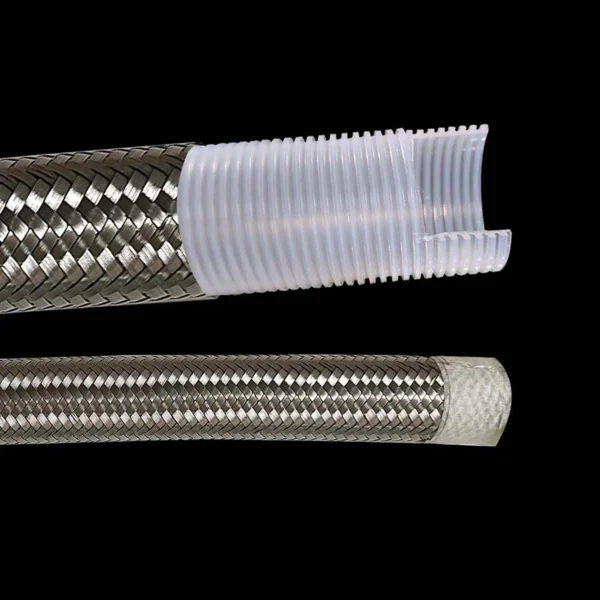

Hochleistungs-Kraftstoffschlauch aus gewelltem PTFE-Geflecht – weich, antihaftbeschichtet, chemikalienbeständig

Mehrzweck-Kraftstoffschlauch aus gewelltem PTFE-Geflecht mit Metallverstärkung bietet geringes Gewicht, Flexibilität bei niedrigen Temperaturen und flammhemmende Eigenschaften. Ideal für Heizungs-, Lüftungs- und Klimatechnik, Luft- und Raumfahrt sowie Laborgeräte.

Heavy Wall Vacuum Hoses: The Tank of the Hose World

Alright, let’s start with the heavy wall crew. These bad boys are built like tanks—thicker PVC or rubber layers that shrug off impacts and wear like nothing. Imagine a hose wall that’s 1/4-inch thick on a 1/4-inch inner diameter; that’s not flimsy tubing, that’s armor. They’re ace for straight runs where you need raw durability, say in construction vacs hauling gravel or shop vacs gobbling metal shavings.

From my days troubleshooting on-site, heavy wall hoses excel in spots with constant abrasion. One time, we swapped a standard hose for a heavy wall in a foundry—guy was sucking up slag that’d chew through lesser lines. Boom, no more mid-shift swaps. The thickness boosts collapse resistance, hitting full vacuum (29 inHg) without a whimper, and they’re often cheaper upfront.

But here’s the rub—they’re heavier, which means more drag when you’re maneuvering. Flexibility? Eh, not their strong suit. Bend radius can be twice that of slimmer options, so if your setup twists like a pretzel, you might fight ’em. Temp-wise, they handle -40°F to 140°F easy, but extremes push ’em toward cracking if not rated right.

Key perks in a nutshell:

- Durability on Steroids: That extra material laughs at punctures and scrapes.

- Cost-Effective for Basics: Great entry point for non-chemical hauls.

- Vacuum Resistance Reinforcement Built-In: No add-ons needed; the wall does the heavy lifting.

Downsides? Weight and stiffness. If you’re lugging this around a factory floor all day, your back’ll thank you for skipping it.

Wire Reinforced Vacuum Hoses: Flexibility Meets Muscle

Now, flip to wire reinforced—specifically, the steel wire helix hose variety. These have a coiled wire snake running through the wall, like rebar in concrete. It keeps the hose from collapsing under vacuum, even when you’re yanking it around corners or sucking up wet muck.

I’ve fitted these in tight pharma lines where space is premium, and man, the flex is a game-changer. The helix—usually 110-ton psi steel—adds tensile strength without bulking up the whole thing. Per ISO 7233 guidelines for vacuum resistance, these hold steady at high negatives with minimal deformation, often under 10% shortening in tests. Perfect for dynamic jobs, like mobile vac trucks or lab transfers where hoses dance daily.

Take a steel wire helix hose: it’s ozone-resistant, flame-retardant, and grounds static if wired right—crucial for flammable dust pulls. In one setup I consulted on, a woodshop went from zapping operators to smooth sails just by ditching plain hoses for helix-reinforced. Flow rates? Up 15-20% smoother thanks to less internal drag.

They’re lighter than heavy walls, too—easier on the arms—and handle similar temps, but shine in chemical resistance if the outer layer’s beefed up. Cost a tad more, but longevity evens it out.

Quick hits:

- Bend Without Breaking: Tight radii, no kinks—ideal for routed installs.

- Static-Smart: Helix grounds charges, cutting spark risks.

- Versatile Vacuum Resistance Reinforcement: Scales from light duty to heavy debris hauls.

Catch? The wire can snag if exposed, and they’re pricier for custom lengths.

PTFE-Kraftstoffschlauch mit antihaftbeschichtetem Metallgewebe – extreme Temperaturbeständigkeit (-70 °C bis 260 °C)

Hochtemperatur-PTFE-Metallgewebeschlauch Vereint Flexibilität und thermische Stabilität. Wird häufig in Automobilabgassystemen, Dampfleitungen und kryogenen Anwendungen eingesetzt. Beständig gegen Adhäsion, Abrieb und chemischen Abbau.

Heavy Wall vs. Wire Reinforced Vacuum Hose: The Showdown Table

To make this crystal, here’s a side-by-side on heavy wall vs. wire reinforced vacuum hose. Pulled from real specs I’ve spec’d out over the years, aligned with ASTM tests for fair play.

| Besonderheit | Heavy Wall Vacuum Hose | Wire Reinforced (Steel Wire Helix Hose) |

|---|---|---|

| Collapse Resistance | Excellent (full 29 inHg, thick wall) | Superior (helix prevents 10%+ deformation per ISO 7233) |

| Flexibility/Bend Radius | Fair (wider turns needed, stiffer) | Great (tight bends, kink-proof) |

| Gewicht | Heavier (e.g., 1.5 lbs/ft for 2″ ID) | Lighter (0.8-1 lb/ft, easier handling) |

| Abriebfestigkeit | Top-tier (thick material eats wear) | Good (reinforcement helps, but outer layer key) |

| Temperaturbereich | -40°F to 140°F standard | -40°F to 160°F, better for heat spikes |

| Cost per Foot | $2-4 (budget-friendly basics) | $3-6 (pays off in flex/durability) |

| Am besten für | Straight, abrasive hauls (e.g., shop vacs) | Dynamic, routed apps (e.g., vac trucks) |

This ain’t exhaustive—your exact needs tweak it—but it’s a solid starting line. See how wire reinforced edges in versatility? That’s why it often wins for pros juggling setups.

When Vacuum Resistance Reinforcement Steals the Show

Sometimes, you need that extra oomph in vacuum resistance reinforcement. Think high-vac systems pulling 28+ inHg, where standard hoses pancake. Both types deliver, but layer ’em smart: heavy wall for wallop, helix for hold.

In abrasive worlds like mining or recycling, reinforcement means life or death for flow. Data from hose assemblers shows unreinforced lines fail 40% faster under vacuum with grit. Add a steel wire helix hose, and you’re golden—minimal flow loss, even coiled tight.

Pro tip from the trenches: always match to your pump’s CFM. Undersized reinforcement? You’ll throttle efficiency by 25%. I’ve audited lines where folks skimped, only to chase leaks weekly. Don’t be that guy.

Heavy Duty PTFE: The Upgrade You Didn’t Know You Needed

Okay, level up—heavy duty PTFE hoses. These aren’t your grandpa’s PVC; polytetrafluoroethylene (PTFE) is the gold standard for nasty environments. Chem-resistant to acids, bases, you name it—doesn’t swell or dissolve in solvents. Temp swing? -200°C to 260°C, no sweat.

Why PTFE for vacuum? Low friction means high flow—up to 20% better than rubber—and that vacuum resistance reinforcement pairs killer with braided or convoluted designs. At Teflon X, our PTFE Corrugated Braided Fuel Hose is a beast: corrugated for flex, braided stainless for burst strength, handling full vacuum in fuel transfers or chem vacs. It’s got that heavy duty PTFE core, shrugging off corrosives while keeping flows smooth.

I’ve specced these for a chem plant swapping old lines—cut failures by half, per their logs. Non-stick surface? Cleans in seconds, slashing downtime. If your ops involve volatiles or heats, PTFE’s your quiet hero.

Real Talk: Success Stories That Stuck With Me

Let’s get personal—I’ve got stories that’ll make you nod. Take “Factory X” (keeping it anon), a Midwest manufacturer sucking powders through long runs. Their heavy wall hoses worked okay but kinked in bends, dropping vac by 15 inHg. Switched to steel wire helix hose with vacuum resistance reinforcement? Flows stabilized, output up 12%. No more mid-batch halts.

Or “Lab Y,” battling static in solvent pulls. Plain reinforced? Zaps everywhere. Added a grounded helix setup—zero incidents, per OSHA logs. And in auto repair? A shop I advised went heavy duty PTFE for brake fluid vacs. Lasted three years vs. six months on PVC. These aren’t hypotheticals; they’re from boots-on-ground fixes.

One quirky win: a food processor with wet vacs. Heavy wall was too stiff for overhead routing; wire reinforced flexed perfect, and PTFE lining kept it sanitary. Saved ’em on CIP cycles—clean-in-place, for the uninitiated.

These bits show how tailoring heavy wall vs. wire reinforced vacuum hose to your chaos pays dividends. Unique angle? Pair PTFE with helix for hybrid heaven—tough, clean, flexible.

PTFE-Balgschlauch: Innen flach, außen gewellt für den Einsatz in der Pharmaindustrie

Der PTFE-Faltenbalgschlauch mit flacher Innen- und gewellter Außenwand bietet hygienische, kontaminationsfreie Leistung für pharmazeutische Anwendungen. Dieser PTFE-Schlauch mit glatter Innenwand und gewellter Außenwand ermöglicht einen reibungslosen Produkttransfer und ist beständig gegen aggressive Desinfektionsmittel.

Das für sterile Umgebungen geeignete Wellrohr mit innen flacher, außen gewellter Oberfläche sorgt für Reinheit bei Arzneimittelherstellungsprozessen und bietet Flexibilität ohne Kompromisse bei der Festigkeit.

Entscheiden Sie sich für dieses PTFE-Wellrohr mit Innen- und Außenflachwellung, um die Effizienz zu steigern. Seine balgartige Struktur, ähnlich der von PTFE-Wellrohren mit Innen- und Außenflachwellung, gewährleistet die Einhaltung strenger Industriestandards.

Smart Moves: How to Nail Your Hose Pick

Alright, you’re hooked—now what? Start with your pain points. High abrasion? Lean heavy wall. Twisty paths? Wire reinforced all day. Chem exposure? Layer in heavy duty PTFE.

Audit time: measure your vac levels (use a gauge, duh), note temps, and list hazards. Budget? Factor lifecycle—cheaper hoses cost more long-term. At Teflon X, we run sims on https://teflonx.com/ to match your specs.

Don’t sleep on fittings—mismatched ones tank performance. And test! Per NAHAD guidelines, proof your assembly at 1.5x working pressure.

Wrapping this: choosing between heavy wall vs. wire reinforced vacuum hose boils down to your grind. Want unyielding strength? Heavy. Need agility with backbone? Wire. Crank it with PTFE for the win.

Feeling that itch for a custom run? Hit up the team at Teflon X—we’ve got the heavy duty PTFE chops to dial it in. Swing by https://teflonx.com/ for deets, or drop a line to Allison.Ye@teflonx.com. Quote’s free, advice is better. What’s your toughest vac headache? Let’s chat and fix it.

FAQ: Quick Hits on Vacuum Hose Headaches

Q: Can I mix heavy wall and wire reinforced features in one hose?

A: Totally—hybrids exist, like heavy duty PTFE with a steel wire helix hose embed. Boosts vacuum resistance reinforcement without sacrificing flex. Seen it slash wear in dual-duty lines.

Q: How do I know if my current hose meets ASTM vacuum standards?

A: Grab a vac gauge and test collapse at full pull. ASTM F450-09 calls for no more than 5% deformation under load. If it flops, time for an upgrade. Pro move: log it yearly.

Q: What’s the real edge of heavy duty PTFE over basic reinforced hoses?

A: Chem immunity and flow—PTFE cuts drag by 15%, per flow tests, and handles 260°C swings. For high-strength vac, it’s like night and day in sticky apps.

Q: How often should I replace a steel wire helix hose in heavy use?

A: Depends on abuse, but inspect quarterly. In abrasive vacs, figure 1-2 years; helix keeps ’em kicking longer than plain walls.