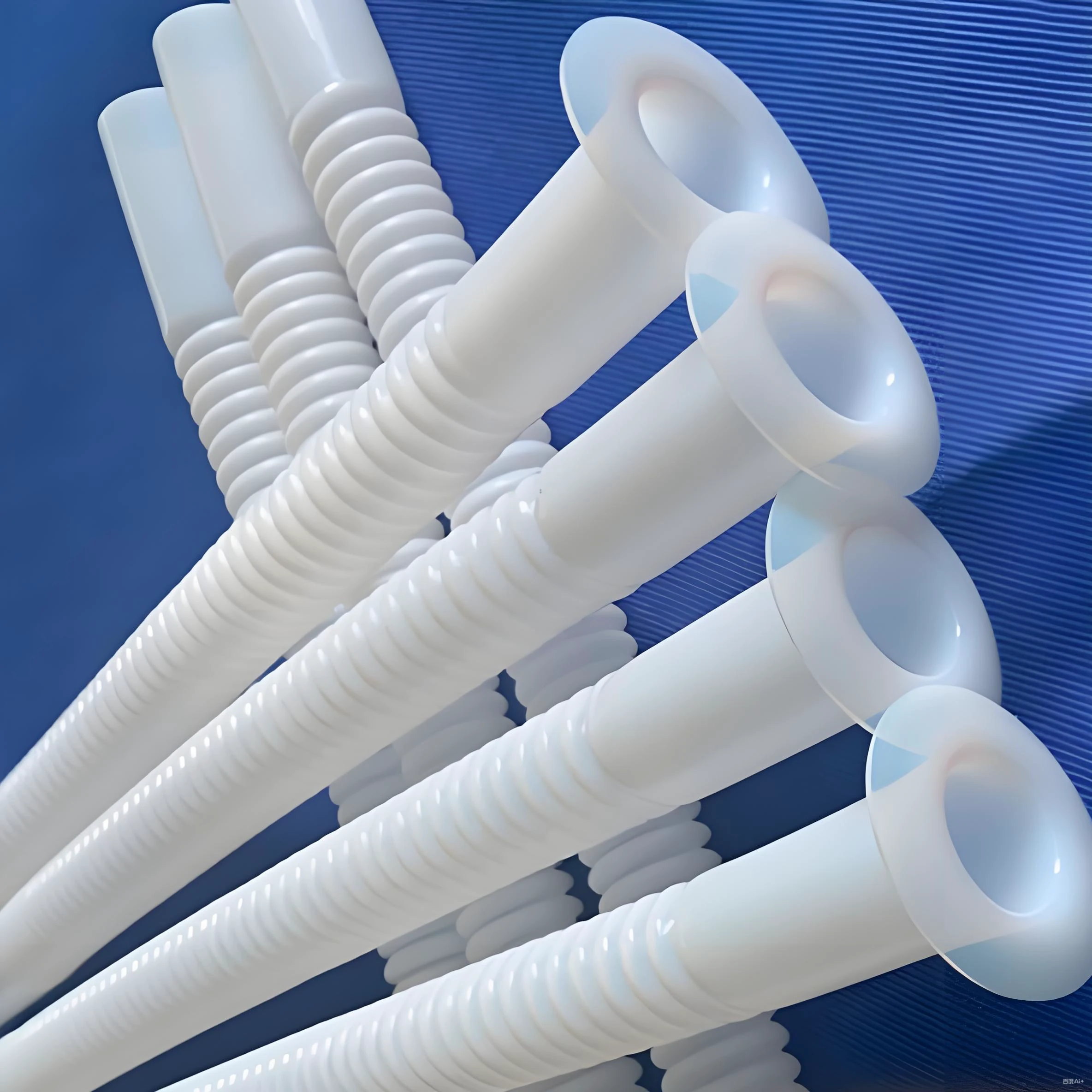

High Pressure PTFE Hose Flared Ends – For Demanding Hydraulic Jobs

Elevate your hydraulic and pneumatic systems with the Teflon X High Pressure PTFE Hose with Flared Ends, designed for superior strength and reliability in the most challenging environments. This robust High Pressure PTFE Hose with Flared Ends delivers unmatched safety, durability, and performance, making it the go-to solution for demanding applications where high pressures and corrosive media are involved.

Engineered with a premium PTFE (Polytetrafluoroethylene) liner and stainless steel braid reinforcement, our High Pressure PTFE Hose with Flared Ends offers exceptional resistance to chemicals, extreme temperatures, and intense pressures. The innovative flared ends design ensures a secure, leak-proof connection, minimizing downtime and enhancing system integrity. Ideal for hydraulic jobs that require precision and resilience, this High Pressure PTFE Hose with Flared Ends outperforms standard hoses by providing a smooth, non-contaminating flow path even under maximum stress.

Key Features of Teflon X High Pressure PTFE Hose with Flared Ends

- High-Pressure Capability: Rated for up to 3,000 PSI or more, perfect for hydraulic systems handling extreme loads without compromise.

- Flared Ends Integration: Flare-thru construction allows seamless fitting attachment, reducing potential failure points in High Pressure PTFE Hose with Flared Ends Setups.

- Chemical and Corrosion Resistance: PTFE liner withstands acids, solvents, and harsh fluids, ensuring longevity in aggressive industrial settings.

- Thermische Stabilität: Operates reliably from -65°F to 500°F (-54°C to 260°C), suitable for both cryogenic and high-heat applications.

- Flexibility and Kink Resistance: Stainless steel braid provides superior bend radius and durability, ideal for dynamic routing in tight spaces.

- Static Dissipation Option: Conductive PTFE variants available for grounding in explosive or static-sensitive environments.

- Custom Fabrication: Tailored lengths, diameters, and end fittings to fit your specific High Pressure PTFE Hose with Flared Ends requirements.

Der High Pressure PTFE Hose with Flared Ends from Teflon X combines heavy-duty construction with user-friendly installation, setting a new standard for hydraulic performance.

Technische Spezifikationen

The following table details the standard parameters for the Teflon X High Pressure PTFE Hose with Flared Ends. These specs are derived from industry benchmarks for high-pressure PTFE hoses, ensuring optimal compatibility and safety in hydraulic applications.

| Parameter | Specification | Details |

|---|---|---|

| Material (Liner) | PTFE (Polytetrafluorethylen) | Smooth bore, chemically inert liner for contamination-free transfer; optional conductive core for static dissipation. |

| Reinforcement | 304/316 Stainless Steel Braid | Enhances pressure handling and flexibility; corrosion-resistant for long-term use. |

| Endbeschläge | Flared Ends (Flare-Thru Design) | Direct PTFE-to-fitting seal prevents leaks and metallic contamination; compatible with JIC 37° flare connections. |

| ID Range | 1/4″ to 2″ (6mm to 50mm) | Scalable for various hydraulic flow rates; custom IDs available. |

| OD Range | 0.5″ to 2.75″ (12mm to 70mm) | Adjusted based on braid layers for added strength in high-pressure scenarios. |

| Maximum Working Pressure | Up to 4,000 PSI (276 bar) | Size-dependent; burst pressure tested to 4x working pressure for safety. |

| Temperaturbereich | -65°F to 500°F (-54°C to 260°C) | Full performance across wide thermal extremes, including vacuum ratings. |

| Biegeradius | 4x ID (minimum) | Maintains flow integrity and resists kinking in mobile equipment. |

| Länge | Up to 100 ft (30m) per assembly | Extended options for complex routing; custom cuts for precision fits. |

| Standards Compliance | SAE 100R14, FDA (for compatible media), ISO 9001 | Meets hydraulic, sanitary, and quality standards for industrial use. |

| Conductivity | Optional Static Dissipative PTFE | Ensures safe dissipation in hazardous locations. |

Note: Exact ratings may vary with customization. Consult Teflon X for pressure curves, material certifications, and application-specific advice on your High Pressure PTFE Hose with Flared Ends.

Anwendungen

Der Teflon X High Pressure PTFE Hose with Flared Ends is engineered for high-stakes environments where reliability is non-negotiable:

- Hydraulic Systems: Powering heavy machinery, presses, and construction equipment with high-pressure fluid transfer.

- Pneumatic Operations: Delivering compressed air or gases in automated manufacturing lines.

- Chemical and Petrochemical: Transporting corrosive fluids in refineries and processing plants.

- Aerospace and Automotive: Precision connections for fuel, hydraulic, and coolant systems under extreme conditions.

- Marine and Offshore: Withstanding saltwater exposure and high-pressure demands in rugged settings.

Das High Pressure PTFE Hose with Flared Ends optimizes flow efficiency, reduces maintenance, and boosts operational safety across these sectors.

Warum Teflon X wählen?

Teflon X leads in PTFE innovations, offering the High Pressure PTFE Hose with Flared Ends with rigorous testing and expert support. Our commitment to quality ensures your systems run smoother and safer. Browse our collection at Teflon X.

Ready to upgrade? Contact us through our Kontaktseite oder E-Mail Allison.Ye@teflonx.com for quotes, samples, or custom High Pressure PTFE Hose with Flared Ends solutions. We’re here to power your success!

Bewertungen

Es gibt noch keine Bewertungen.