Produktübersicht

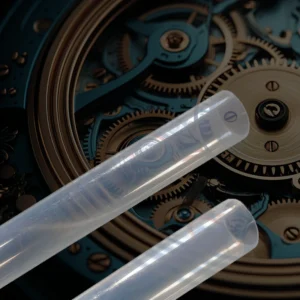

Enhance your electrical connections with Teflon X’s innovative transparenter Schrumpfschlauch connectors sleeves, crafted from premium PFA material for optimal insulation and effortless maintenance. Our transparenter Schrumpfschlauch sleeves deliver exceptional transparency, allowing quick visual verification of terminations while providing robust protection against oils, acids, and extreme temperatures. The smooth, non-stick surface ensures easy cleaning and prevents residue buildup, making this transparenter Schrumpfschlauch solution perfect for marine and automotive applications where reliability is paramount. Designed for superior durability, Teflon X’s transparenter Schrumpfschlauch connectors sleeves combine high clarity with industrial-grade performance, safeguarding wires and components in harsh environments.

Teflon X excels in fluoropolymer expertise, offering transparenter Schrumpfschlauch products that prioritize safety, longevity, and ease of use. Browse our full selection at https://teflonx.com/, or reach out via the Kontaktseite oder E-Mail Allison.Ye@teflonx.com for customized transparenter Schrumpfschlauch solutions tailored to your needs.

Hauptmerkmale

- Unmatched Transparency: Crystal-clear design in transparenter Schrumpfschlauch sleeves for seamless visual inspection and termination verification.

- Superior Insulation Properties: High dielectric strength ensures reliable electrical protection with every transparenter Schrumpfschlauch application.

- Easy-Clean, Non-Stick Surface: Smooth finish resists oils, acids, and debris, simplifying maintenance for transparenter Schrumpfschlauch in demanding settings.

- Extreme Temperature Resistance: Handles -200°C to +260°C continuously, ideal for marine and automotive transparenter Schrumpfschlauch exposures.

- Chemical and Corrosion Resistance: Withstands harsh substances without degradation, extending the lifespan of transparenter Schrumpfschlauch protected connections.

- Low Friction for Easy Installation: Glides smoothly over connectors, reducing effort and wear in transparenter Schrumpfschlauch assembly processes.

- UV and Abrasion Resistance: Maintains clarity and integrity outdoors, supporting versatile transparenter Schrumpfschlauch use in exposed environments.

- Flexible 2:1 Shrink Ratio: Conforms tightly to irregular shapes for secure, professional transparenter Schrumpfschlauch fits.

- High Purity and Flame Retardancy: Meets UL standards for safe, contamination-free transparenter Schrumpfschlauch in sensitive applications.

Technische Spezifikationen

Teflon X transparenter Schrumpfschlauch connectors sleeves are built to exceed industry benchmarks. Below is a detailed table of standard parameters:

| Parameter | Specification | Hinweise |

|---|---|---|

| Material | Perfluoroalkoxy (PFA) | Fluoropolymer for superior performance |

| Farbe | Clear/Transparent | High optical clarity for visual inspection |

| Shrink Ratio | 2:1 | Expands to fit over components, shrinks to 50% of original diameter |

| Operating Temperature | -200°C to +260°C (continuous) | Short-term up to +300°C; suitable for cryogenic to high-heat uses |

| Shrink Temperature | 150°C – 200°C | Quick recovery with standard heat sources like hot air guns |

| Durchschlagsfestigkeit | >15 kV/mm | Excellent insulation for high-voltage applications |

| Zugfestigkeit | ≥25 MPa | High mechanical durability |

| Elongation at Break | ≥300% | Flexible and resistant to cracking |

| Hardness (Shore D) | 55 – 65 | Balances flexibility with rigidity |

| Specific Gravity | 2.15 g/cm³ | Lightweight yet robust |

| Flammability | UL 224 VW-1 | Self-extinguishing, low smoke generation |

| Standard Sizes (ID) | 1.0 mm – 50 mm | Custom sizes available upon request |

| Wall Thickness (Recovered) | 0.2 mm – 2.0 mm | Thin walls for space-constrained designs |

Note: Specifications are based on standard testing methods (e.g., ASTM D2671). For exact values tailored to your application, contact Teflon X.

Anwendungen

Teflon X transparenter Schrumpfschlauch connectors sleeves excel in high-stakes environments:

- Marine and Automotive: Protects terminations from saltwater, oils, and vibrations with durable transparenter Schrumpfschlauch insulation.

- Electrical Connections: Insulates splices and harnesses, enabling easy visual checks via transparenter Schrumpfschlauch transparency.

- Industrial Machinery: Shields against acids and extreme temps in processing equipment using reliable transparenter Schrumpfschlauch.

- HVAC and Plumbing: Non-stick transparenter Schrumpfschlauch prevents buildup for clean, efficient wire management.

- Electronics and Sensors: High-purity transparenter Schrumpfschlauch supports contamination-free assemblies in medical and lab settings.

Unser transparenter Schrumpfschlauch products align with UL, RoHS, and industry-specific standards for seamless compliance.

Why Choose Teflon X’s Clear Heat Shrink Connectors Sleeves?

With a legacy of fluoropolymer innovation, Teflon X’s transparenter Schrumpfschlauch sleeves offer unparalleled clarity, easy-clean functionality, and insulation excellence that outpace standard options. ISO-certified quality and customizable sizing ensure your projects benefit from proven performance in marine, automotive, and beyond. Secure your connections today—contact us at Allison.Ye@teflonx.com oder https://teflonx.com/contact-us/ for samples, quotes, or expert advice on transparenter Schrumpfschlauch integration.

Bewertungen

Es gibt noch keine Bewertungen.