Produktübersicht

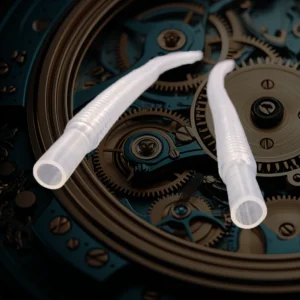

Teflon X introduces the Flexible Corrosion-Resistant PTFE Braided Teflon Fuel Hose, an advanced solution optimized for demanding industrial environments. This Teflon-Kraftstoffschlauch features a soft PTFE inner liner that ensures smooth, unrestricted flow in aggressive media, making it indispensable for chemical transfer, oil applications, and fuel handling. Engineered with corrosion-resistant PTFE and robust braiding, our Teflon-Kraftstoffschlauch withstands extreme conditions while maintaining flexibility and durability. Ideal for food processing, pharmaceutical, and semiconductor industries, this Teflon-Kraftstoffschlauch delivers non-toxic, low-friction performance that prevents contamination and supports high-purity operations. With its corrugated design, the Teflon-Kraftstoffschlauch from Teflon X offers superior bendability, self-draining capabilities, and resistance to kinking, ensuring reliable conveyance of fuels like E85 ethanol, gasoline, solvents, and corrosive fluids. Discover how our Teflon-Kraftstoffschlauch elevates efficiency and safety—explore more at Teflon X.

Hauptmerkmale

- Außergewöhnliche Korrosionsbeständigkeit: PTFE liner provides inertness against acids, solvents, fuels, and aggressive chemicals, preventing degradation in harsh environments.

- Wide Temperature Tolerance: Performs reliably from -200°C to +260°C (-328°F to +500°F), suitable for cryogenic cooling and high-heat processes.

- Enhanced Flexibility: Corrugated structure with braided reinforcement allows tight bend radii, reduces kinking, and accommodates vibration in dynamic applications.

- Low-Friction and Non-Stick Surface: Ensures high flow rates, easy cleaning, and minimal buildup, critical for hygienic and fuel transfer systems.

- High-Pressure Capability: Rated up to 5000 PSI, with burst pressures exceeding 4x working pressure for safety in oil and chemical lines.

- Non-Contaminating and FDA-Compliant: White or conductive black PTFE options meet USP Class VI and 3A standards, perfect for food, pharma, and semiconductor uses.

- Full Vacuum and Steam Compatibility: Handles vacuum applications and steam without collapse, adding versatility for diverse industrial needs.

- Customizable Braiding: Stainless steel or alternative materials for tailored strength and conductivity to mitigate static risks in fuel handling.

Anwendungen

Teflon X Teflon-Kraftstoffschlauch is engineered for precision in high-stakes sectors where reliability and purity are paramount:

- Fuel and Oil Transfer: Seamless handling of gasoline, E85 ethanol, diesel, and lubricants in automotive, aerospace, and oil & gas operations.

- Chemische Verarbeitung: Corrosion-free conveyance of acids, solvents, and reactive media without leaching or contamination.

- Food and Pharmaceutical: Hygienic, non-toxic flow in compliant environments, supporting sterile processing and ingredient transfer.

- Halbleiterfertigung: Low-particle, high-purity lines for ultra-clean gases and chemicals in sensitive fabrication.

- General Industrial: Pump connections, steam lines, and hydraulic systems requiring flex-resistant, low-friction hoses under pressure.

Specifications

For bespoke configurations, consult our specialists. Below is a summary of standard parameters for the Flexible Corrosion-Resistant PTFE Braided Teflon Fuel Hose:

| Parameter | Specification Details |

|---|---|

| Innendurchmesser (ID) | 1/4″ to 4″ (6mm to 100mm); custom sizes available up to 6″ |

| Outer Diameter (OD) | Varies by ID and braiding; e.g., 0.5″ to 4.5″ |

| Working Pressure | Up to 5000 PSI (depending on size and braid layers) |

| Burst Pressure | 4x Working Pressure (minimum) |

| Temperaturbereich | -200 °C bis 260 °C (-328 °F bis 500 °F) |

| Minimum Bend Radius | 4x ID (e.g., 1″ for 1/4″ ID hose) |

| Länge | Custom up to 1000 ft; standard assemblies to spec |

| Material – Liner | PTFE (Conductive Black or Non-Conductive White) |

| Material – Braid | 300-Series Stainless Steel (Single or Double Layer) |

| Fittings | Swaged/Crimped; Brass, SS, Hastelloy, or Titanium |

| Vacuum Rating | Full Vacuum (29.9″ Hg) |

| Standards | FDA, USP Class VI, 3A; Conductive options for ATEX compliance |

Note: Specifications may vary based on custom configurations. Always verify with Teflon X for your specific application.

Why Choose Teflon X’s Teflon Fuel Hose?

Backed by years of fluoropolymer innovation, Teflon X’s Teflon-Kraftstoffschlauch undergoes stringent testing for leak-proof integrity and extended service life. This commitment to excellence means our Teflon-Kraftstoffschlauch surpasses industry standards, minimizing risks and optimizing costs in fuel, chemical, and oil applications.

Elevate your operations today—browse Teflon X or connect via our Kontaktseite. Email: Allison.Ye@teflonx.com.

Bewertungen

Es gibt noch keine Bewertungen.