Produktübersicht

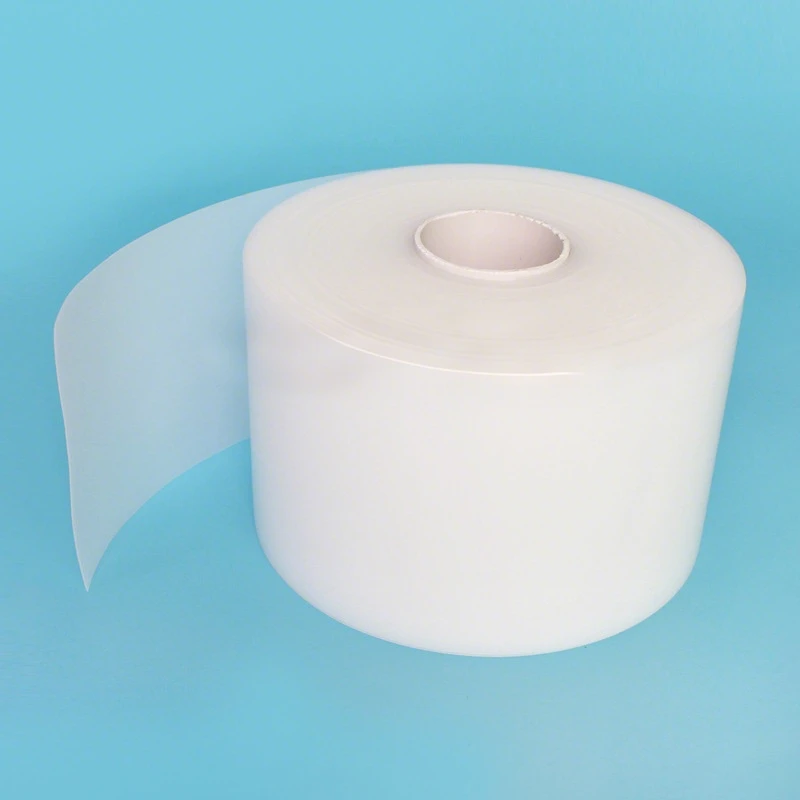

Elevate your industrial and filtration solutions with Teflon X’s premium UPE Membrane, a cutting-edge UHMWPE Film designed for unparalleled durability and performance. As a leading UPE Membrane solution, this Ultra-High Molecular Weight Polyethylene (UHMWPE) material boasts exceptional wear resistance, outperforming carbon steel by 8× in high-friction environments. Its inert molecular structure guarantees stability across acidic, alkaline, and saline conditions, making our UPE Membrane the go-to choice for demanding applications.

This self-lubricating UHMWPE Film minimizes energy loss and preserves low-temperature flexibility, ensuring seamless operation in extreme settings. FDA-compliant and non-toxic, Teflon X’s UPE Membrane is trusted in medical packaging, automotive components, and advanced filtration systems. With molecular weights exceeding 3,000,000 g/mol, it delivers superior toughness and versatility. Explore how our UPE Membrane can transform your projects—visit teflonx.com today.

Hauptfunktionen und Vorteile

Teflon X UPE Membrane excels through its advanced polymer composition, offering these standout attributes for enhanced reliability:

- High Wear Resistance: 8× better than carbon steel, ideal for abrasive industrial linings and high-friction machinery.

- Self-Lubricating Properties: Ultra-low friction coefficient reduces wear and energy consumption in dynamic systems like conveyors and guides.

- Chemical Stability: Inert to acids, alkalis, solvents, and saline solutions, with negligible moisture absorption for long-term performance.

- Impact and Toughness: Exceptional shock absorption and elongation, maintaining integrity in low-temperature environments down to -200°C.

- Biocompatibility: Non-toxic, odorless, and FDA-approved, perfect for medical and food-contact uses without compromising safety.

- Filtration Efficiency: Microporous options provide high permeability and selectivity for separation processes in batteries and wastewater treatment.

- Versatile Format: Available as films, sheets, or custom membranes, with adjustable porosity for tailored UPE Membrane Anwendungen.

As a robust UHMWPE Film, our UPE Membrane outperforms traditional materials, combining the strength of HDPE with amplified resilience for cost-effective innovation.

Anwendungen

Teflon X UPE Membrane powers critical processes across industries, leveraging its wear resistance and chemical stability:

- Industrial Filtration Systems: Gas separation, chemical filters, and wastewater treatment, where high flux and durability ensure efficient operation.

- Medical and Biomedical: Sterile packaging, orthopedic implants, and drug delivery devices, benefiting from biocompatibility and low friction.

- Automotive and Aerospace: Protective linings, bushings, and lightweight components for impact resistance and reduced maintenance.

- Chemische Verarbeitung: Valves, pumps, storage tanks, and safety equipment in corrosive environments.

- Energy and Electronics: Separators in lithium-ion batteries and ultracapacitors, enhancing safety and performance.

- General Manufacturing: Chute linings, conveyor belts, and machine guards to combat abrasion and extend service life.

From precision UPE Membrane filtration to rugged industrial uses, Teflon X delivers reliable UHMWPE Film solutions.

Technische Spezifikationen

Below is a comprehensive table of standard parameters for Teflon X’s UPE Membrane (UHMWPE Film). Custom configurations are available—contact us for personalized UPE Membrane options.

| Eigentum | Value/Range | Test Standard/Notes |

|---|---|---|

| Material Type | Ultra-High Molecular Weight Polyethylene (UHMWPE) | ASTM D4020 |

| Molecular Weight | >3,000,000 g/mol | Gel Permeation Chromatography |

| Dichte | 0.93 g/cm³ | ASTM D792 |

| Tensile Yield Strength | 19.3–23 MPa | ASTM D638 |

| Elongation at Break | >300% | ASTM D638 |

| Shore D Hardness | 60–65 | ASTM D2240 |

| Impact Strength (Izod) | No Break (Unnotched) | Highest among thermoplastics |

| Reibungskoeffizient | 0.05–0.15 (Dynamic) | Comparable to PTFE |

| Verschleißfestigkeit | 8x Carbon Steel | Taber Abrasion Test |

| Operating Temperature | -200°C to +80°C | Continuous Use |

| Chemische Beständigkeit | Excellent (Acids, Alkalis, Solvents) | Except Oxidizing Acids |

| Wasseraufnahme | <0.01% (24 hrs) | ASTM D570 |

| Dicke | 0.1–5 mm | Customizable |

| Breite | Up to 2 m | Roll or Sheet Format |

| FDA-Konformität | Yes (Non-Toxic, Food Contact Safe) | 21 CFR 177.1520 |

| Porosity (Microporous) | 30–70% (Optional) | For Filtration Grades |

Note: Values are typical and may vary based on processing and grade. For detailed datasheets, visit teflonx.com.

Warum Teflon X wählen?

Teflon X leads in polymer innovation, providing top-tier UPE Membrane products with stringent quality assurance. Our UHMWPE Film surpasses standards, integrating effortlessly into your workflows for superior results. Enjoy worldwide delivery and dedicated expertise as your partner in UPE Membrane excellence.

Transform your applications with Teflon X’s high-performance UPE Membrane—browse options at teflonx.com or connect via our Kontaktseite. Email inquiries to Allison.Ye@teflonx.com.

Bewertungen

Es gibt noch keine Bewertungen.