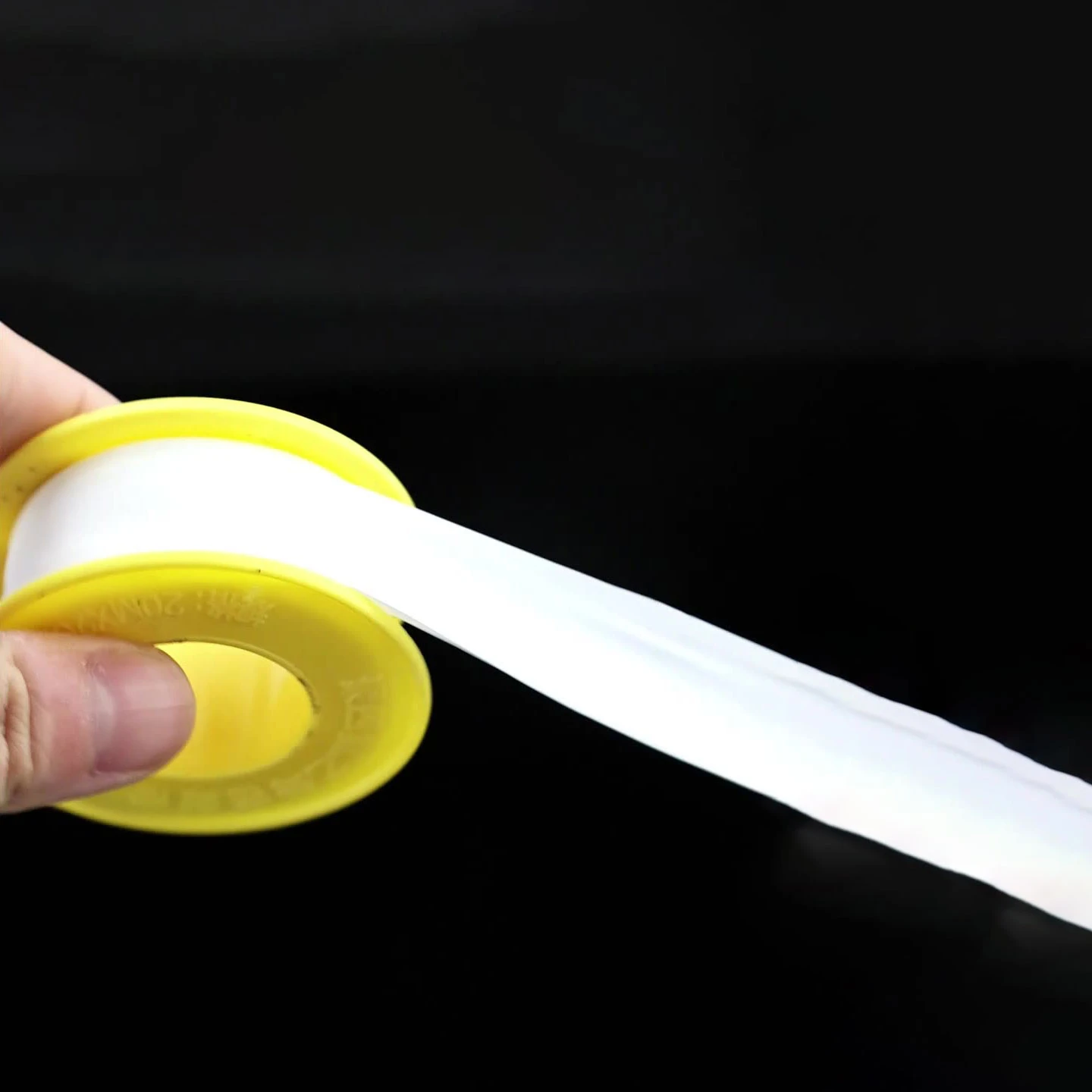

Gelbes PTFE-Band für Gasleitungen | Gewindedichtband mit hoher Dichte

Willkommen bei Teflon X, the industry authority on advanced sealing solutions. When safety is the top priority, professionals turn to our Gelbes PTFE-Band für Gasleitungen. Engineered specifically for the rigorous demands of the gas industry, this premium gelbes Fadendichtband offers a robust, high-density solution that far exceeds the capabilities of standard sealing tapes. Whether you are installing a residential stove or maintaining industrial gas infrastructure, our tape provides the ultimate leak protection.

Why Choose Yellow PTFE Tape for Gas Applications?

Gas lines carry volatile substances like natural gas, propane, and butane, which are composed of smaller molecules than water. This means they can escape through microscopic thread imperfections that water might not penetrate. Standard weißes Klempnerband or generic weißes Teflonband typically lacks the density required to effectively seal these gases under pressure.

Unser gelbes PTFE-Band is manufactured with a significantly higher density and thickness. This “maximum density” construction allows the PTFE-Dichtungsband to fill thread roots more effectively, creating an impenetrable barrier against gas leaks. It is the designated color code for the gas industry, ensuring that inspectors and contractors can visually verify that the correct Teflon-Gewindedichtband has been used for the job.

Key Features and Safety Benefits

Using the correct Teflon-Rohrband is critical for compliance and safety. Our PTFE-Band für Gas offers distinct advantages:

- High Density Formulation: Unlike standard Klempnerband, our yellow tape is heavy-duty, meaning fewer wraps are needed to achieve a solid seal.

- Chemische Inertheit: It is resistant to all common gases and harsh chemicals, preventing the tape from degrading or dissolving over time.

- Temperature Stability: Capable of withstanding extreme temperature fluctuations, making it suitable for both heating systems and cryogenic applications.

- Non-Hardening Seal: Der Teflon-Fadenband remains pliable, allowing for easy disassembly of fittings without seizing or galling the threads.

- Vibration Resistance: The thick nature of the gelbes Fadendichtband absorbs vibration better than liquid sealants, ensuring the joint stays tight over time.

Comparison: Yellow vs. White Plumbers Tape

It is important to distinguish between our products to ensure the right application. While our weißes Teflonband is excellent for water pipes, it is generally thinner and less dense. Our gelbes PTFE-Band acts as a specialized PTFE-Klempnerband for gas, meeting approval standards for handling flammable gases. Attempting to use standard weißes Klempnerband on gas lines is a safety risk and often a code violation. Always choose Teflon X gelbes Fadendichtband for gas, propane, or butane lines.

Technische Spezifikationen

For engineers and procurement officers, the following table details the technical parameters of our Yellow PTFE Tape. These specifications ensure our product meets the stringent requirements of the gas industry.

| Parameter | Details zur Spezifikation |

|---|---|

| Product Name | Yellow Gas Line PTFE Thread Seal Tape |

| Material | 100% Pure Polytetrafluoroethylene (PTFE) |

| Farbe | Yellow (Industry Standard for Gas) |

| Dichte | High Density: > 1.2 g/cm³ (vs 0.3 g/cm³ for standard white tape) |

| Dicke | 0.1mm – 0.25mm (Double thickness options available) |

| Standard Widths | 1/2″ (12mm), 3/4″ (19mm), 1″ (25mm) |

| Temperaturbereich | -268°C to +260°C (-450°F to +500°F) |

| Druckbewertung | High Pressure Resistance (Up to 10,000 PSI depending on fittings) |

| Compatible Media | Natural Gas, Propane, Butane, Nitrogen, Air, Steam, Water |

| Zugfestigkeit | ≥ 10 Mpa |

Installation Guide for Gas Lines

Proper installation is vital when using PTFE-Band für Gas. Follow these steps for a secure connection:

- Clean Threads: Ensure male and female threads are free of oil, dirt, and metal shavings.

- Start Correctly: Lay the end of the gelbes Fadendichtband on the second thread from the end of the pipe. Crucial: Do not cover the first thread, as this prevents tape shreds from entering the gas line and clogging valves.

- Wrap Direction: Wrap the tape clockwise (with the threads). If you wrap backward, the tape will unravel when you tighten the fitting.

- Apply Tension: Pull the tape taut as you wrap so it seats deeply into the grooves.

- Number of Wraps: Due to the thickness of our high-density teflon pipe tape, 2 to 3 full wraps are usually sufficient. Do not over-wrap.

- Finish: Tear the tape and smooth the end into the threads. Tighten the joint securely.

Contact Teflon X for Gas Safety Solutions

Ensure your projects are compliant and safe with Teflon X. We are a premier supplier of high-quality PTFE-Gewindeband suitable for the most demanding environments. Whether you need bulk wholesale rolls of gelbes PTFE-Band or standard Teflonband für Sanitärinstallationen, we have the stock and expertise to support you.

Get a Quote or Technical Support:

Email our sales team directly at: allison.ye@teflonx.com

Learn more about our full product line at: https://teflonx.com/

Bewertungen

Es gibt noch keine Bewertungen.