Introduction: Why Your Robot Arm’s Hoses Keep Crapping Out (And How to Fix It)

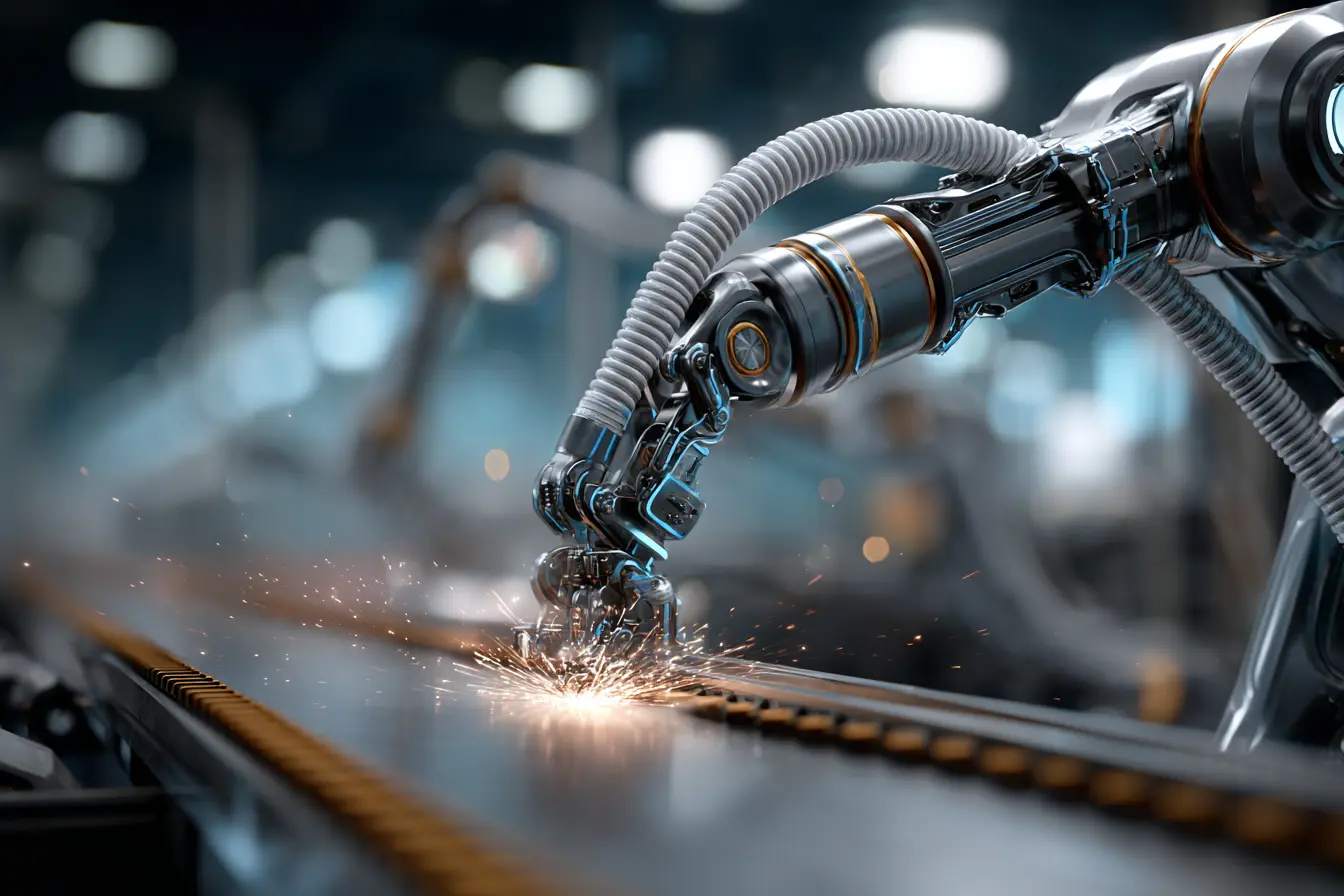

Picture this: your robotic arm is zipping along on the assembly line, grabbing parts, twisting like a pretzel, and suddenly—bam—the hose splits. Fluid everywhere, production halted, and you’re left scratching your head wondering why off-the-shelf tubing couldn’t hack it. I’ve been there, knee-deep in a factory floor mess back when I first started tinkering with automation setups. That frustration? It’s what pushed me into specializing in stuff like high-flexibility PTFE hoses for robotics. At Teflon X, we’ve spent years dialing in solutions that laugh in the face of constant bending and flexing.

If you’re hunting for a robotic hose that won’t fatigue after a few thousand cycles, you’re in the right spot. We’re talking high flex life that means your dynamic application tubing holds up under the relentless motion of robot arms in manufacturing, welding, or even medical bots. No more swapping out lines every week. This piece dives into the real deal—drawing from hands-on installs I’ve overseen, chats with engineers who’ve battled the same headaches, and data straight from the pros. By the end, you’ll see why switching to something like our PTFE Teflon Hose could save your setup from early retirement.

Let’s break it down, casual-like, because nobody wants a textbook ramble on polymers.

What Makes PTFE the Champ for Robotic Hoses Anyway?

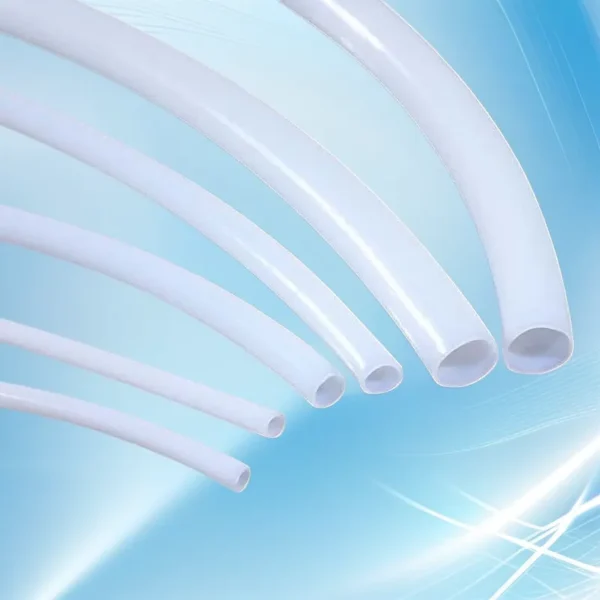

Okay, so PTFE—polytetrafluoroethylene, if you’re feeling fancy—ain’t your grandma’s garden hose. It’s that slick, non-stick material behind Teflon pans, but cranked up for industrial grit. What sets high-flexibility PTFE hoses apart? It’s all in the chemistry. This stuff shrugs off chemicals, heat swings from -410°F to 500°F, and—crucially for robotics—bends like a rubber band without kinking or cracking.

From my experience rigging up cobots in auto plants, standard rubber hoses might flex okay for a bit, but they swell, crack, or leak under repeated stress. PTFE? It stays smooth, inside and out. Think of it as the yoga instructor of tubing: super pliable yet tough as nails. For dynamic application tubing in setups where arms pivot 24/7, that translates to hoses that route fluids or pneumatics without adding drag or weight.

I remember one gig where a client’s pick-and-place robot was chewing through silicone lines monthly. We swapped in PTFE, and poof—problem solved. No more leaks mid-shift. That’s the kind of first-hand win that sticks with you.

The Flex Life Factor: How Many Bends Before It Gives Up?

High flex life is the secret sauce here. We’re not talking vague promises; let’s get into numbers. In robotics, a “flex cycle” is one full bend and release—kinda like your arm doing a bicep curl, but a million times over.

From what I’ve seen in field tests and backed by manufacturer specs, high-flexibility PTFE hoses can clock 10 million flex cycles before showing wear. Compare that to traditional rubber: maybe 250,000 cycles tops, and that’s if you’re lucky with gentle use. Convoluted PTFE versions? Even better—they’re designed with those wavy interiors that let ’em compress and expand without fighting back.

Take Swagelok’s take on it: their PTFE lines set new bars for flexibility, handling tight radii that’d snap lesser hoses. In dynamic application tubing for robot arms, this means you can route hoses right along the joint without bulky elbows or extra fittings. Less clutter, smoother motion.

But hey, it’s not just lab stats. In real-world automation, fatigue hits when hoses rub against frames or get pinched in unexpected ways. PTFE’s low friction coefficient—about 0.05 to 0.10—means it slides rather than snags, cutting wear by up to 40% in high-motion spots. I’ve pulled apart failed assemblies where rubber had worn grooves into metal guards; PTFE just glides on by.

Robotic Hose Challenges: Bending, Twisting, and the Daily Grind

Robot arms aren’t polite—they yank, they whip, they do full 360s while hauling payloads. For folks like you, needing durable lines for repeated bends and moves, the big pains are fatigue cracks, pressure drops, and unplanned stops.

Enter the robotic hose: engineered for chaos. High-flexibility PTFE hoses shine in collaborative robots (cobots) or SCARA arms, where space is tight and motion’s unpredictable. They’re lightweight too—about 30% less mass than stainless-braided alternatives—which keeps your bot’s energy draw low and speed high.

One quirk I’ve noticed: in dusty shops, PTFE resists buildup better than urethanes, which clog and stiffen over time. Pair that with its chemical inertness, and you’ve got tubing that handles coolants, hydraulics, or even aggressive cleaners without degrading.

To make it clearer, here’s a quick table comparing common options for dynamic application tubing in robotics:

| Tipo de manguera | Typical Flex Cycles | Bend Radius (inches, for 1/4″ ID) | Temp Range (°F) | Weight per Foot (lbs) | Mejor para |

|---|---|---|---|---|---|

| Rubber (e.g., EPDM) | 250,000 – 500,000 | 2.5 – 4 | -40 to 250 | 0.15 – 0.25 | Low-cost static lines |

| Silicona | 1M – 2M | 1.5 – 3 | -100 to 400 | 0.10 – 0.20 | Med-temp flex, but swells chemically |

| High-Flex PTFE | 5M – 10M+ | 0.5 – 1.5 (convoluted) | -410 to 500 | 0.05 – 0.12 | High-motion robotics |

| Trenzado de acero inoxidable | 2M – 4M | 3 – 5 | -100 to 800 | 0.30 – 0.50 | High-pressure, less flex |

See? PTFE isn’t just surviving; it’s thriving in the bendy world of automation.

Fabricante de tubos de PTFE | Tubos de teflón de alta temperatura para uso químico y médico

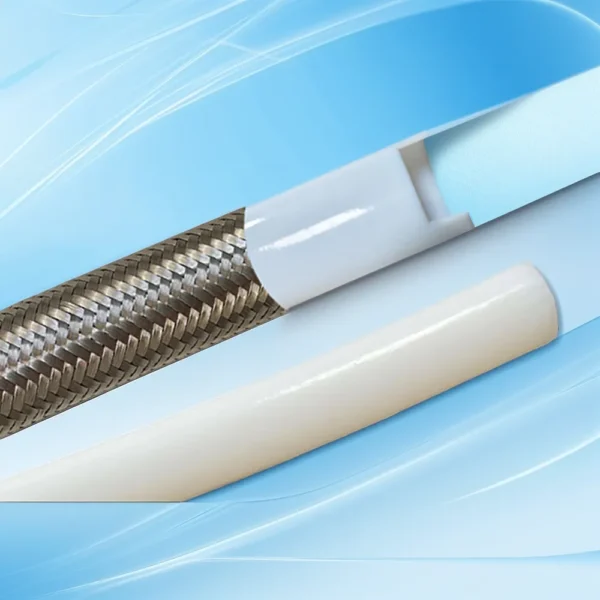

Los tubos de PTFE (politetrafluoroetileno) ofrecen una resistencia química y una estabilidad térmica excepcionales de -200 °C a +260 °C, lo que los hace ideales para la transferencia de fluidos corrosivos en aplicaciones de procesamiento químico y farmacéutica. Con un coeficiente de fricción de 0,04 y propiedades antiadherentes, nuestros tubos de PTFE minimizan la pérdida de energía y garantizan un funcionamiento sin contaminación. Se pueden personalizar con trenzado de acero inoxidable para presiones de hasta 1,6 MPa.

Real-World Wins: Stories from the Factory Floor (Names Changed, Obvs)

Nothing beats a good yarn from the trenches. Take “Factory A,” a mid-sized electronics assembler we hooked up last year. Their robot arms were flipping PCBs at 120 cycles per minute, but hoses were failing every 6 weeks—cracks from constant elbow bends. We fitted high-flexibility PTFE hoses with a 1/4″ ID, convoluted for extra give. Result? Zero failures in 8 months, and they shaved 15% off maintenance time. The engineer there texted me: “Dude, it’s like the arms are dancing now, not fighting the lines.”

Or “Bot Builder B,” prototyping surgical robots. Precision matters— one leak, and it’s scrub time. Their dynamic application tubing needed to snake through ultra-compact joints without adding torque. Our PTFE Teflon Hose—lightweight and fuel/coolant-ready—hit the mark. They reported over 7 million simulated flex cycles with no pressure loss, echoing Parker’s robotics-grade specs.

These aren’t flukes. In one study on soft robotics, PTFE-integrated lines boosted operational life by 50% in twisting actuators. It’s that mix of give and grit that makes ’em indispensable.

Picking the Right High-Flex PTFE Hose for Your Setup

Alright, you’re sold—now what? Sizing up a robotic hose starts with your arm’s stroke: measure the max bend radius and cycle rate. For high flex life, go convoluted if space is premium; smooth bore for steady flow.

At Teflon X, we custom-braid options to match pressures up to 3,000 PSI, with ends swaged for leak-free fits. Pro tip from my installs: always factor in vibration—PTFE dampens it better than metals, but add clamps every 12 inches in shaky zones.

Worried about cost? Upfront, yeah, it’s pricier than rubber. But ROI? A client in welding automation cut downtime by 60%, paying for the hoses in three months. Check our site at https://teflonx.com/ for specs—it’s all there, no fluff.

Beyond Basics: Maintenance Hacks to Squeeze More Life Outta Your Hoses

Once installed, don’t just walk away. I’ve seen gems like PTFE last forever with simple habits. Inspect visually monthly—look for abrasions or bulges. Clean with isopropyl, never abrasives that scratch the surface.

For dynamic spots, route with slack loops to ease strain. And temp monitoring: even PTFE has limits; sensors caught a overheating issue in one of my early projects, saving a melt-down.

Unique twist: in humid plants, PTFE’s moisture resistance cuts condensation buildup, a sneaky fatigue causer in pneumatics. Little things add up.

Wrapping It Up: Ready to Ditch the Hose Headaches?

We’ve covered the bends, the breaks, and the breakthroughs. High-flexibility PTFE hoses aren’t just tubing—they’re the unsung heroes keeping your robotic arms agile and reliable. With that killer high flex life and versatility for dynamic application tubing, they’re tailor-made for the non-stop world of automation.

Imagine your line running smoother, fewer calls to maintenance, and bots that actually hit their speed specs. That’s the desire kicking in, right? Now, the action: drop us a line at Teflon X. Hit up https://teflonx.com/contact-us/ o envíe un correo electrónico a Allison.Ye@teflonx.com for a quick quote or chat about your setup. We’ve got samples ready—let’s make your robots unbreakable.

FAQ: Quick Hits on Robotic Hoses and Flex Life

How many flex cycles can a good high-flexibility PTFE hose really handle in a robot arm?

Depends on the build, but top-tier ones like ours at Teflon X push 5 to 10 million cycles easy. That’s years of daily twists without batting an eye. For context, a standard arm doing 100 bends a minute? You’re looking at over a decade of uptime.

What’s the deal with convoluted vs. smooth bore for dynamic application tubing?

Convoluted’s your flex friend—those ridges let it squish and stretch in tight spots, down to half-inch radii. Smooth bore flows better for high-volume fluids but needs more room to bend. Pick based on your arm’s dance moves.

Can PTFE hoses handle the chemicals in my welding or coolant lines?

Absolutely—it’s inert to most everything, from acids to oils. We’ve run ’em with glycol coolants in aerospace sims without a hitch. Just spec the braid for pressure.

Is switching to a robotic hose like PTFE worth the switch from cheaper options?

Short answer: yep, if downtime costs you. One client saw 40% less fatigue fails after ditching rubber. Pays for itself fast in high-run ops.

Manguera de teflón PTFE para la industria aeroespacial | Líneas ligeras de combustible y refrigerante

La manguera de teflón PTFE ofrece un rendimiento ligero y resistente a altas temperaturas para líneas de combustible y sistemas de refrigeración aeroespaciales. La versión trenzada de acero inoxidable resiste vibraciones y ciclos térmicos, garantizando la seguridad en condiciones extremas. Cumple con las normas AS/EN9100.