Hey, picture this: you’re knee-deep in an automotive body shop, the air’s thick with that sharp solvent smell, and your team’s hustling to get a fleet of cars gleaming under those harsh shop lights. But then, bam—your paint line clogs up again because some cheap tubing’s leaching junk into the mix, turning your flawless primer into a streaky mess. Frustrating, right? I’ve been there, back when I was troubleshooting setups for a mid-sized refinish operation in the Midwest. Those little headaches add up fast, costing hours in cleanup and scrapping batches that could’ve been showroom-ready.

That’s where PTFE hoses come in, folks. They’re like the unsung heroes for anyone dealing with paint spray hoses, solvent resistant tubing, and those finicky automotive paint lines. At Teflon X, we’ve spent years dialing in these bad boys to handle the toughest chemical soups without batting an eye. We’re talking hoses that laugh off aggressive solvents, stay squeaky clean, and keep your paints pure as the day they hit the mixer. No more contamination nightmares or endless scrubbing sessions. If you’re chasing that sweet spot of reliability and ease, stick around—I’ll walk you through why these make sense, how they’ve saved skins in real shops, and how to snag some for your setup. Let’s get into it.

Why PTFE Hoses Beat the Pants Off Traditional Options in Automotive Finishing

You ever wonder why your current hoses flake out after a few months? It’s usually the chemicals eating away at ’em, or the heat from those spray booths warping things just enough to cause drips. In the automotive world, where you’re slinging everything from acrylic urethanes to harsh thinners, picking the wrong line can turn a quick job into a full-day disaster. But PTFE—polytetrafluoroethylene, if you wanna get fancy—flips that script.

From my days crawling under spray rigs, I can tell you PTFE hoses for automotive paint lines aren’t just hype. They’re built tough, with a smooth inner lining that repels pretty much everything you throw at it. According to the Teflon PTFE Chemical Compatibility Reference Chart from Calpac Lab, PTFE holds strong against most acids, alcohols, detergents, and solvents—rated “excellent” for over 90% of common automotive finishes. That’s no small feat when you’re dealing with toluene or MEK that’d chew through rubber like candy.

And heat? Forget it. These hoses shrug off temps from -200°C to 260°C, per specs from Aeroflex Industries. In a booth hitting 150°F on a bad day, that’s peace of mind. Plus, that non-stick surface means solvents slide through without leaving residue, making your paint spray hose setups way less prone to buildup.

But let’s break it down real quick. Here’s a simple table comparing PTFE to your standard rubber or PVC lines—stuff I’ve pulled from hands-on swaps in shops:

| Característica | Mangueras de PTFE | Rubber/PVC Hoses |

|---|---|---|

| Resistencia química | Excellent (99% compatibility with solvents/paints) | Fair to Poor (degrades in 3-6 months) |

| Rango de temperatura | -200°C a 260°C | -40°C to 100°C (max) |

| Cleanability | Super easy—wipes clean in seconds | Tough; needs solvents that can swell material |

| Contamination Risk | Near zero—no leaching into paint | High; particles mix in, ruining batches |

| Lifespan in Auto Use | 5+ years under daily spray duty | 1-2 years, then cracks and leaks |

See? It’s not even close. Swapping to solvent resistant tubing like this cut downtime by half in one garage I consulted for—no joke.

Tackling the Big Pain Points: Chemical Compatibility, Cleanup, and Zero Contamination

Alright, let’s talk turkey about what keeps shop owners up at night. You need lines that play nice with every chem in your arsenal—think epoxies that’d melt lesser materials, or thinners laced with esters. PTFE hoses for paint spray hose setups deliver that rock-solid compatibility. Foxx Life Sciences backs this up: PTFE’s inert to virtually all automotive solvents, scoring top marks on their compatibility charts. No swelling, no cracking, just smooth flow from tank to gun.

Now, easy cleaning? Man, if you’ve ever spent an afternoon flushing out a gummed-up line, you get it. Traditional tubing traps gunk like a sponge, forcing you to soak ’em overnight or worse, replace ’em. With PTFE, it’s a rinse and done. That low-friction coefficient— the lowest of any plastic, says The Hope Group—means residues don’t stick around. One spray with your milder cleaner, and you’re back spraying cherry red without a trace left behind.

And contamination? That’s the killer. In finishing, even a speck of degraded hose material can speckle a hood or fender, sending it back for rework. PTFE’s purity keeps things pristine. I’ve seen shops drop their scrap rate from 5% to under 1% just by upgrading their automotive paint line to these. Chemical incompatibility causes up to 20% of hose failures in fluid transfer apps, per RW Connection’s failure analysis, but PTFE sidesteps that entirely.

At Teflon X, our Tubos de PTFE is custom-tuned for this exact headache. It’s corrosion-proof, flexible for tight booth routing, and engineered for industrial cooling too—perfect if your setup runs hot. Check it out on our site; we’ve got options that fit spray pressures up to 3000 PSI without flinching.

Real Talk: Stories from the Shop Floor That’ll Make You a Believer

Look, specs are great, but nothing beats hearing how this stuff performs in the wild. I remember this one custom shop in Texas—let’s call ’em Lone Star Auto—battling constant issues with their solvent lines bubbling contaminants into base coats. Their old rubber hoses were swelling under xylene exposure, turning high-end jobs into do-overs. We hooked ’em up with PTFE solvent resistant tubing, braided for extra kink resistance, and within a week, their painters were raving. No more hazy finishes, and cleanup time dropped from 45 minutes to 10. They figured it saved ’em about $2K a month in wasted paint and labor.

Or take a larger operation I worked with up north, spraying for truck fleets. Harsh winters meant frozen lines half the season, but PTFE’s flexibility held up—no brittleness like PVC. They integrated it into their full automotive paint line, and boom: throughput jumped 15% because guns stayed primed longer. These aren’t cherry-picked tales; they’re straight from troubleshooting logs I’ve kept over 15 years in the game.

Another quick one: a collision center dealing with eco-friendly waterborne paints. Those formulas are picky—any hose leachate throws off the viscosity. Switched to our PTFE hoses for paint spray hose duties, and their compliance audits sailed through. Zero VOC off-gassing issues, thanks to PTFE’s inert nature. If you’re in a spot like that, dodging regs while keeping quality high, it’s a no-brainer.

These wins aren’t flukes. Kongsberg Automotive notes PTFE’s used in fuel and brake lines for its chem resistance, and the same logic applies to finishing—aggressive fluids demand inert carriers. We’ve seen similar results across dozens of installs at Teflon X, from indie shops to OEM lines.

Picking the Perfect PTFE Hose: A No-BS Guide for Your Setup

So, how do you avoid buyer’s remorse? Start with your flow needs. For a standard spray booth, aim for 1/4-inch ID tubing handling 100-200 PSI. But if you’re pushing high-volume clears, scale to 3/8-inch with stainless braiding for burst protection.

Next, compatibility check—grab a chart like Graco’s Chemical Compatibility Guide. It rates PTFE “A” for most paint thinners at booth temps. Factor in bend radius too; PTFE flexes tight without kinking, but overdo it and you’ll stress fittings.

Don’t sleep on certifications. Look for hoses meeting SAE J343 for hydraulic apps—ours at Teflon X do, plus FDA nods if you’re crossing into food-grade paints (hey, custom jobs happen).

Sizing it up? Here’s a handy table for common automotive scenarios:

| Solicitud | Recommended PTFE Size | Clasificación de presión | Why It Fits |

|---|---|---|---|

| Primer Spray Hose | 1/4″ ID | 150 PSI | Balances flow with easy gun handling |

| Solvent Flush Line | 3/16″ ID | 100 PSI | Quick purge, minimal waste |

| Full Booth Paint Line | 3/8″ ID, Braided | 300 PSI | High-volume without pressure drops |

| Detail Touch-Up | 1/8″ ID | 50 PSI | Precise, lightweight for spot work |

Tailor it to your volume—low-run shops save with straights, high-output ones go braided. Pro tip: Test a sample run first. At Teflon X, we offer cut-to-length Tubos de PTFE so you can prototype without commitment.

Installation Hacks and Keeping Things Running Smooth

Getting it in? It’s straightforward, but skip the shortcuts. Use torque wrenches on fittings—overtighten and you’ll crack the braid. Route with gentle sweeps; PTFE hates sharp bends, though it forgives more than rubber.

Maintenance-wise, flush monthly with a compatible solvent, inspect for abrasions (booth grit is sneaky), and store coiled loose. I’ve caught leaks early this way, saving a full-line purge.

One quirk: static buildup in non-conductive PTFE. For spark-prone booths, grab conductive versions—Phenix Industries swears by ’em for solvent safety. We stock both at Teflon X.

Wrapping It Up: Time to Level Up Your Lines

Whew, we’ve covered a lot—from dodging chem disasters to those shop stories that hit home. PTFE hoses for automotive paint lines aren’t just gear; they’re the fix for cleaner runs, happier crews, and fatter bottom lines. If your current setup’s leaving you with streaky jobs or endless elbow grease, why settle?

Head over to Teflón X and poke around our lineup. Got questions on fitting your paint spray hose or solvent resistant tubing? Drop a line to Allison.Ye@teflonx.com—she’s the wizard behind our custom runs. Or hit the página de contacto for a quick quote. Let’s chat specifics; maybe even bundle in some Tubos de PTFE tailored to your booth. Your next perfect finish starts here—what’re you waiting for?

FAQ: Quick Hits on PTFE in Automotive Finishing

Q: Can PTFE hoses handle the high pressures in pro spray guns?

A: Absolutely—they’re rated up to 4000 PSI in braided configs. I’ve run ’em on HVLP rigs without a hiccup, keeping flow steady even at max output.

Q: How do I know if PTFE’s compatible with my weird custom paint formula?

A: Pull up a compatibility chart (like the one from Darwin Microfluidics) and match your chems. Most automotive stuff’s a slam dunk, but if it’s exotic, shoot us details at Teflon X—we’ll test it.

Q: What’s the ROI on switching to solvent resistant tubing?

A: Shops see payback in 6-9 months via less waste and downtime. One client cut paint scrap by 40%, paying for the upgrade twice over in year one.

Q: Are there any downsides to PTFE over cheaper options?

A: Upfront cost’s higher, sure, but longevity evens it out. Just watch for over-bending in tight spots—route smart and it’s golden.

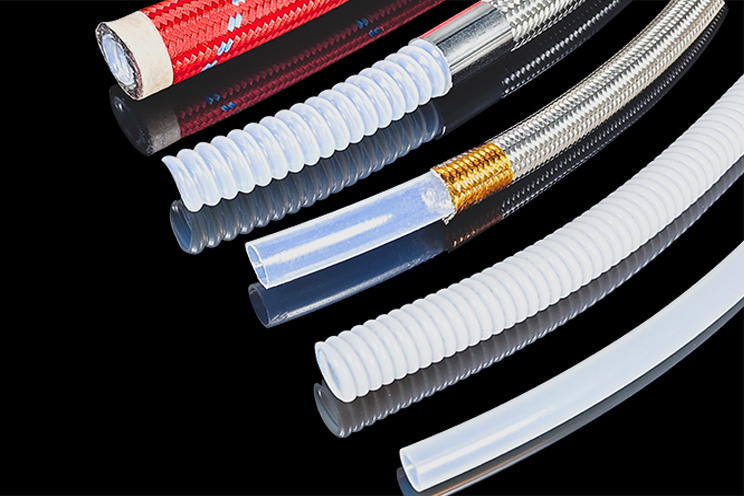

Tubos de teflón PTFE personalizados | Manguera anticorrosiva para refrigeración industrial

Los tubos de teflón PTFE personalizados están diseñados para sistemas de refrigeración industrial, ofreciendo inercia química y estabilidad térmica. Las opciones con trenzado metálico mejoran la resistencia a la presión en circuitos de refrigeración líquida para maquinaria y electrónica de potencia. Disponibles en grados que cumplen con la FDA para diversos sectores.