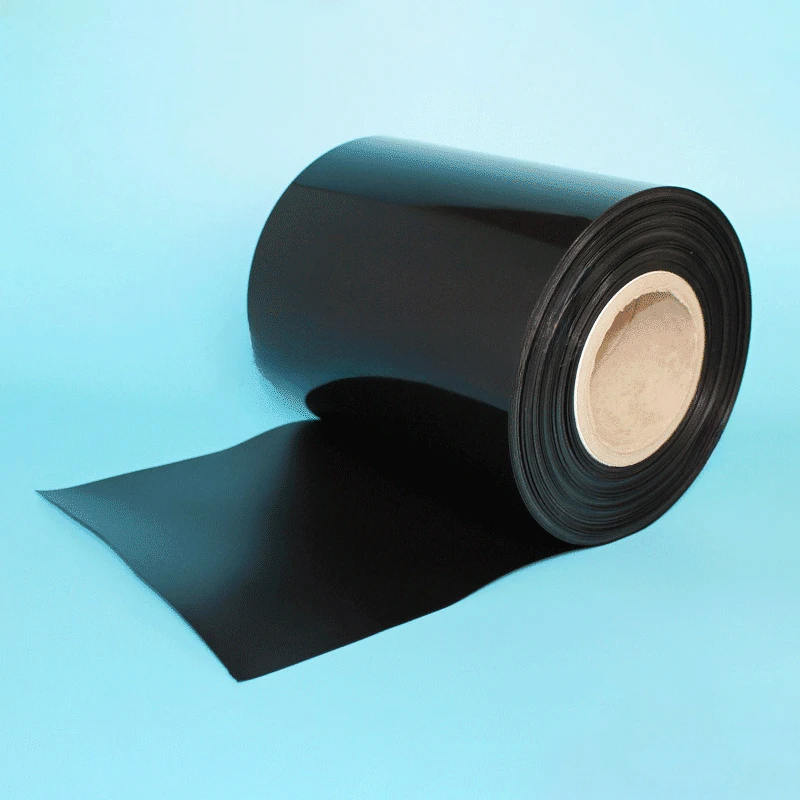

Présentation du produit

Experience unparalleled protection and efficiency with Teflon X’s UHMWPE Film, a cutting-edge Ultra-High Molecular Weight Polyethylene (UHMWPE) solution meticulously designed for superior shock absorption and dynamic performance. This high-impact UHMWPE Film absorbs energy 6× more effectively than ABS polymers, making it the go-to choice for applications demanding resilience against shocks, vibrations, and impacts without cracking or failure. Combined with an ultra-low friction coefficient (0.05–0.15) and exceptional chemical resistance, our UHMWPE Film extends service life in automotive components, machinery parts, and industrial linings, reducing wear and eliminating the need for external lubricants.

Téflon X UHMWPE Film boasts self-lubricating properties that minimize drag and energy loss, while its inherent toughness—rooted in molecular weights exceeding 3,000,000 g/mol—ensures it outperforms traditional materials in high-stress environments. From -200°C cryogenic flexibility to +80°C thermal stability, this lightweight (0.93 g/cm³ density), non-toxic UHMWPE Film resists corrosion from acids, alkalis, and solvents, thriving in harsh conditions. Ideal for sliding mechanisms where low friction and high impact strength converge, our UHMWPE Film drives innovation in automotive, aerospace, and industrial sectors—explore its versatility at teflonx.com.

Principales caractéristiques et avantages

Engineered from premium UHMWPE, Teflon X’s UHMWPE Film delivers these critical properties, optimized for shock absorption, low-friction operation, and long-term reliability:

- Superior Shock Absorption: Absorbs impact energy 6× better than ABS polymers, with no-break Izod strength to handle heavy shocks, vibrations, and drops without deformation or fracture.

- Ultra-Low Friction Coefficient: Self-lubricating surface (0.05–0.15 dynamic) reduces drag, noise, and wear in sliding mechanisms, comparable to PTFE for lubricant-free performance.

- High Impact Strength: Highest among thermoplastics, retaining toughness even at low temperatures, ideal for protective barriers and dynamic machinery components.

- Résistance chimique: Inert to corrosive chemicals, moisture (<0.01% absorption), and UV exposure, ensuring durability in automotive fluids, industrial cleaners, and harsh environments.

- Wear and Abrasion Resistance: Up to 15× more resistant than carbon steel, extending lifespan in high-contact applications like gears, guides, and conveyor linings.

- Thermal Versatility: Stable from -200°C to +80°C with low thermal expansion, maintaining flexibility and integrity in fluctuating temperature conditions.

- Lightweight and Tough: Low density for easy integration, with elongation >300% for energy dissipation in impact-prone uses like bumpers and fenders.

- Eco-Friendly Compliance: Non-toxic, recyclable, and FDA-compliant, supporting sustainable designs in automotive and medical-adjacent industrial applications.

This resilient UHMWPE Film revolutionizes shock-sensitive systems, combining low friction with unmatched impact protection for cost-effective, high-efficiency outcomes.

Applications

Téflon X UHMWPE Film is tailored for environments requiring robust shock absorption and smooth operation, enhancing performance across diverse industries:

- Automotive Components: Vibration dampeners, bumpers, and seals, leveraging high impact strength and low friction to absorb road shocks and reduce squeaks in assemblies.

- Machinery Parts: Wear strips, guide rails, and sliding mechanisms in automation lines, where self-lubrication and chemical resistance minimize maintenance and downtime.

- Industrial Linings: Chute and hopper coatings for material handling, preventing adhesion and absorbing impacts from abrasive flows in mining and logistics.

- Aerospace and Defense: Protective films for lightweight armor and ballistic layers, utilizing superior energy absorption and low weight for enhanced safety.

- Marine and Dock Applications: Fender pads and boat liners, resisting scratches, dents, and impacts while providing low-friction surfaces for docking.

- Bottling and Packaging: Star wheels and conveyor guides, benefiting from high wear resistance and shock tolerance in high-speed, repetitive operations.

From automotive resilience to industrial durability, our UHMWPE Film provides proven low-friction and high-impact solutions for demanding, motion-intensive roles.

Spécifications techniques

Below is a comprehensive table of standard parameters for Teflon X’s UHMWPE Film. Custom variants, such as reinforced or thinner gauges for specific shock absorption needs, are available—contact us for tailored UHMWPE Film configurations.

| Propriété | Value/Range | Test Standard/Notes |

|---|---|---|

| Material Type | Ultra-High Molecular Weight Polyethylene (UHMWPE) | ASTM D4020 |

| Molecular Weight | >3,000,000 g/mol | Gel Permeation Chromatography |

| Densité | 0.93 g/cm³ | ASTM D792 |

| Tensile Yield Strength | 19.3–23 MPa | ASTM D638 |

| Elongation at Break | >300% | ASTM D638 |

| Shore D Hardness | 60–65 | ASTM D2240 |

| Impact Strength (Izod) | No Break (Unnotched) | Highest among thermoplastics |

| Coefficient de frottement | 0.05–0.15 (Dynamic) | Comparable to PTFE |

| Résistance à l'usure | 15x Carbon Steel | Taber Abrasion Test |

| Operating Temperature | -200°C to +80°C | Continuous Use |

| Résistance chimique | Excellent (Acids, Alkalis, Solvents) | Except Oxidizing Acids |

| Absorption d'eau | <0.01% (24 hrs) | ASTM D570 |

| Épaisseur | 0.1–5 mm | Customizable |

| Largeur | Up to 2 m | Roll or Sheet Format |

| Conformité à la FDA | Yes (Non-Toxic, Food Contact Safe) | 21 CFR 177.1520 |

| Porosity (Microporous) | 30–70% (Optional) | For Filtration Grades |

| Rigidité diélectrique | 20–30 kV/mm | ASTM D149 (Estimated for Sheets) |

Note: Values are typical and may vary based on processing and grade. For detailed datasheets, visit teflonx.com.

Pourquoi choisir Teflon X ?

Teflon X sets the benchmark in advanced polymer films, rigorously testing our UHMWPE Film for exceptional shock absorption and low-friction prowess that surpasses competitors. This high-performance UHMWPE Film integrates seamlessly into your designs, absorbing 6× more impact than ABS while slashing wear and lubrication needs, ultimately driving operational savings and reliability. Backed by our innovation-driven expertise, global supply chain, and personalized support, Teflon X empowers your projects with durable UHMWPE Film solutions.

Harness the power of Teflon X’s impact-resistant UHMWPE Film—view our complete range at teflonx.com or inquire through our Page Contactez-nous. For specialized recommendations, email Allison.Ye@teflonx.com.

Avis

Il n’y a pas encore d’avis.