If you’re running a paint shop and dealing with uneven spray patterns day in and day out, you know how frustrating that can be. One minute everything’s going smooth, the next you’re getting streaks, tails, or just patchy coverage that means extra touch-ups and wasted time. I’ve seen it plenty over the years – pressure drops, hoses swelling from solvents, or just plain old wear causing all sorts of headaches. That’s where high-pressure PTFE hoses come in, especially for airless paint spray setups. They’re a game changer for getting that nice, even fan pattern every time.

Let’s talk about what really causes those inconsistent sprays first. From what I’ve experienced on job sites and backed by industry folks, the big culprits are things like insufficient pump pressure leading to poor atomization, clogged or worn tips, thick paint that’s not flowing right, or – and this is huge – issues with your hose. A cheap or worn-out hose can cause pressure fluctuations, especially over longer runs, resulting in tails at the edges of your spray fan or uneven thickness.

Why Hose Choice Matters for Consistent Spray Patterns

In airless paint spraying, your hose is the lifeline carrying paint at super high pressures – we’re talking 2000 to 4000 PSI or more typically. Any restriction, swelling, or degradation in the hose messes with that steady flow. Standard nylon or rubber hoses might handle basic stuff, but when you’re dealing with aggressive solvents in modern paints, they can soften, swell, or break down faster. That leads to pressure drops and uneven patterns.

PTFE (that’s Teflon to most of us) lined hoses with stainless steel braiding fix a lot of these problems. The inner core is super smooth and chemically inert, so paints and solvents just glide through without sticking or causing buildup. No swelling means consistent diameter, which keeps pressure stable from pump to gun. Add the stainless braid, and you’ve got flexibility without kinking, plus burst ratings way up there – often 5000 PSI or higher working pressure.

I’ve switched shops over to these, and the difference is night and day. Sprays come out even, with full fan width and no heavy edges. Less overspray waste too, since the atomization stays spot on.

Key Benefits of High-Pressure PTFE Hoses in Paint Applications

- Solvent Resistance: PTFE handles pretty much any paint solvent without degrading. Unlike nylon, which can swell or crack with strong stuff like ketones or thinners, PTFE stays tough. Industry data shows over 20% of hose failures come from chemical exposure – switching to a good solvent resistant hose cuts that risk big time.

- Stable Pressure for Even Patterns: The smooth bore reduces friction, so you maintain pressure better over long hoses. No more tails from drops – just clean, consistent coverage.

- Durability and Flexibility: Stainless braided means it bends easy without collapsing, great for moving around big jobs. And it lasts longer, reducing downtime.

Here’s a quick comparison table to show why PTFE edges out common alternatives for high pressure painting:

| Hose Type | Pressure Rating (Typical Working) | Solvent Resistance | Flexibility | Common Issues in Paint Spraying | Lifespan Estimate |

|---|---|---|---|---|---|

| Nylon/Fiber Braided | 3000-4000 PSI | Moderate | Good | Swelling from solvents, pressure drops | 1-2 years heavy use |

| Rubber Covered | 2000-3300 PSI | Low | Fair | Degradation, kinking | 6-18 months |

| PTFE Stainless Braided | 4000-7000+ PSI | Excellent | Excellent | Minimal – mostly wear from abrasion | 3-5+ years |

These numbers come from typical manufacturer specs like those from Graco-compatible hoses and industrial suppliers. PTFE ones handle the tough stuff way better.

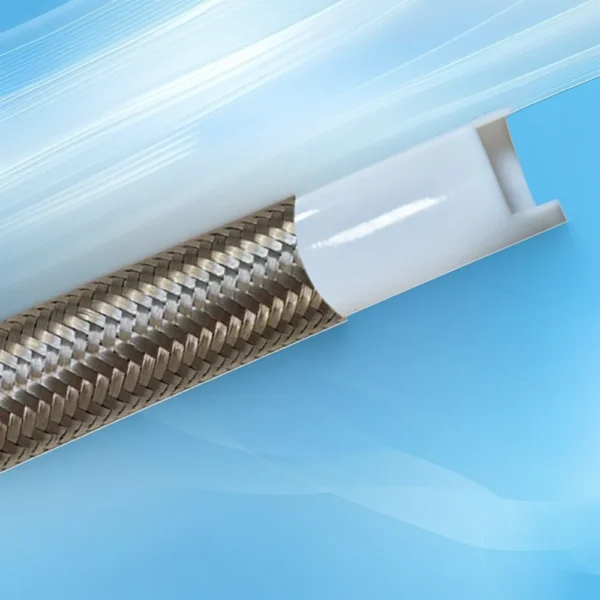

Stainless Steel Braided Teflon Hose | High-Pressure PTFE Lined Tubing

Stainless steel braided PTFE hose combines superior chemical inertness with reinforced mechanical strength, ideal for high-pressure hydraulic systems and aerospace cooling lines. The PTFE inner layer resists acids, alkalis, and solvents, while the metal braiding enhances durability up to 1.6 MPa. Available in ID 1–200 mm for flexible installation.

Real-World Scenarios: How These Hoses Solve Uneven Spraying

Think about a busy coating workshop painting metal parts or furniture. One shop I know (keeping it anonymous, but mid-sized operation) was battling constant uneven patterns on their airless lines. They’d get good sprays close to the pump but tails and streaks further out with 50-foot hoses. Turned out their old nylon airless paint spray hoses were absorbing solvents, changing diameter slightly and causing fluctuations.

They swapped to stainless steel braided PTFE hoses – like our Stainless Steel Braided Teflon Hose at Teflon X – and boom, consistent patterns across the board. Downtime from hose swaps dropped, and finish quality went up. Less rework meant happier customers and more jobs done per day.

Another case: a facility doing high-volume automotive refinishing. Aggressive thinners were eating through standard hoses fast, leading to bursts and messy cleanups. High-pressure PTFE held up, no swelling, steady flow for perfect even coats every pass.

Industry stats back this up – hose failures can cost way more than just replacement, with downtime adding 10-30 times the part cost in lost production. Preventing that with reliable gear like a good high pressure painting hose keeps things running smooth.

Tips for Getting the Best Spray Patterns with PTFE Hoses

- Match your hose ID to the job – 1/4″ for most standard airless paint spray hose needs, bigger like 3/8″ for thicker materials or longer runs to minimize pressure loss.

- Keep it clean – flush thoroughly after use, especially with solvents. PTFE makes this easier since nothing sticks.

- Check fittings and springs – use spring guards to prevent kinks at ends.

- Pair with quality tips – a worn tip will still cause issues, no matter the hose.

- Go for braided – the stainless outer protects against abrasion in busy shops.

At Teflon X, we’ve been supplying these for years, and our Stainless Steel Braided Teflon Hose is built tough for exactly these paint applications. Super resistant to solvents, high pressures no problem, and flexible enough for daily use.

Comparing Hose Materials for Airless Paint Spraying

To make it clearer, let’s break down how PTFE stacks up specifically for consistency:

- Flow Stability: Smooth PTFE inner means low friction – paint moves steady, no pulses.

- Temperature Tolerance: Handles hot or cold without softening or brittling.

- Long-Term Reliability: Less expansion under pressure than others.

If you’re tired of fighting uneven sprays, upgrading to a high-quality airless paint spray hose with PTFE core could be the fix.

Flexible PTFE Tubing | Non-Stick Teflon Tube for Food & Pharma Industries

Flexible PTFE tubing features a non-stick surface, meeting strict hygiene standards for food-grade oil transfer and pharmaceutical sterile filtration. Its bend tolerance and thermal stability (-200°C to +260°C) ensure reliable performance in dynamic environments. Custom lengths and braiding options available.

Maintenance Basics to Keep Patterns Consistent

Even the best hose needs some care. Rinse it out regularly, store coiled loosely, inspect for wear. A little effort goes far in avoiding those frustrating inconsistent days.

We’ve helped plenty of workshop managers sort this out. If inconsistent spraying is hitting your productivity, reach out – we can talk specifics for your setup.

Frequently Asked Questions

What causes uneven spray patterns in airless painting?

A lot of times it’s low pressure, worn tips, thick paint, or hose problems like restrictions or degradation. Fixing the hose often solves a chunk of it.

Are PTFE hoses worth it over cheaper nylon ones for paint spraying?

Yeah, especially if you’re using solvent-based paints or need long hoses. They resist chemicals better, hold pressure steady, and last longer – fewer headaches with patterns.

How do I know if my hose is causing bad spray patterns?

Test with a short whip hose direct from pump. If patterns improve, your main hose might be the issue – swelling, kinks, or wear dropping pressure.

Can high-pressure PTFE hoses handle all types of paints?

Pretty much – water-based, solvent-based, even aggressive stuff. The PTFE lining is inert to most everything.

What’s the best length for an airless paint spray hose?

Depends on the job, but 50 feet is common. Longer needs bigger ID or better material like PTFE to avoid pressure loss.

If this sounds like what your shop needs, check out more at Teflon X. We’ve got options tailored for high pressure painting. Drop us a line at Allison.Ye@teflonx.com or through our contact page for quotes or advice on getting consistent sprays sorted. We’d love to help you dial it in.