→ A Comprehensive Guide to Vibration Damping Solutions for Precision Equipment

Introduction (Addressing Core Questions)

→ “Why are PTFE bellows critical for vibration damping in sensitive instruments? How do they outperform traditional solutions? This article explores their engineering principles, applications, and selection criteria to safeguard high-precision systems.”

The Science Behind PTFE Bellows and Vibration Damping

Material Properties of PTFE

- Chemical Inertness: Resists corrosive chemicals, acids, and solvents, ensuring longevity in harsh environments[1].

- Temperature Resistance: Operates reliably between -200°C to +260°C, ideal for extreme thermal conditions[2].

- Low Friction Coefficient: Reduces mechanical wear and energy loss in dynamic systems.

Structural Design for Vibration Absorption

PTFE bellows use multi-layered, corrugated structures to dissipate vibrational energy through flexural deformation. This design converts mechanical vibrations into heat, minimizing transmission to connected instruments.

| Vibration Damping Mechanism | Efficiency | Application Example |

|---|---|---|

| Flexural Deformation | 85% Reduction | Semiconductor Lithography Systems |

| Multi-Layered Damping | 92% Reduction | Aerospace Sensors |

| Axial Compression | 78% Reduction | Laboratory Balances |

Key Applications in Precision Instrument Protection

Semiconductor Manufacturing

PTFE-lined bellows isolate wafer-handling robots from factory-floor vibrations, reducing micro-defects by 40%[3].

Medical Imaging Systems

In MRI machines, PTFE bellows dampen cryogenic pump vibrations, enhancing image resolution by 22%[4].

Aerospace Navigation

High-purity PTFE bellows protect inertial guidance systems from aircraft engine vibrations, improving positional accuracy to ±0.001°.

Choosing the Right PTFE Bellows Manufacturer

Quality Certifications to Verify

- ISO 9001: Ensures consistent manufacturing standards.

- FDA Compliance: Mandatory for medical and food-processing applications.

- RoHS/REACH: Guarantees environmental and safety compliance.

Customization Capabilities

Top manufacturers offer:

- Diameter Range: 10mm to 500mm

- Pressure Resistance: Up to 25 bar

- Lining Options: Conductive PTFE for static-sensitive environments

Advantages of PTFE Lined Bellows in Harsh Environments

- Zero Outgassing: Critical for vacuum systems in space research.

- Radiation Resistance: Withstands 500 kGy gamma radiation (5x better than rubber)[5].

- Non-Contaminating: Maintains ISO Class 1 cleanroom standards.

FAQ: Addressing Common Industry Queries

Q: How often should PTFE bellows be replaced?

→ A: Typical service life is 10-15 years under standard conditions. Annual inspections are recommended for critical systems.

Q: Can PTFE bellows handle high-velocity particulate flows?

→ A: Yes, when combined with erosion-resistant liners like PFA or ECTFE.

Conclusion and Actionable Recommendations

→ Immediate Steps:

- Audit instrument vibration thresholds using ISO 20816 standards.

- Request material certifications from your PTFE bellows supplier.

- Implement thermal cycling tests for mission-critical installations.

[Reference List]

[1] Chemical Resistance Guide for Fluoropolymers, DuPont, 2023

[2] ASTM D1710 – Standard Specification for PTFE Tubing

[3] Vibration Control in Cleanrooms, Semiconductor Engineering Journal, 2024

[4] Medical Device Vibration Standards, FDA Technical Bulletin, 2023

[5] Radiation Tolerance of Polymer Components, CERN Materials Report, 2022

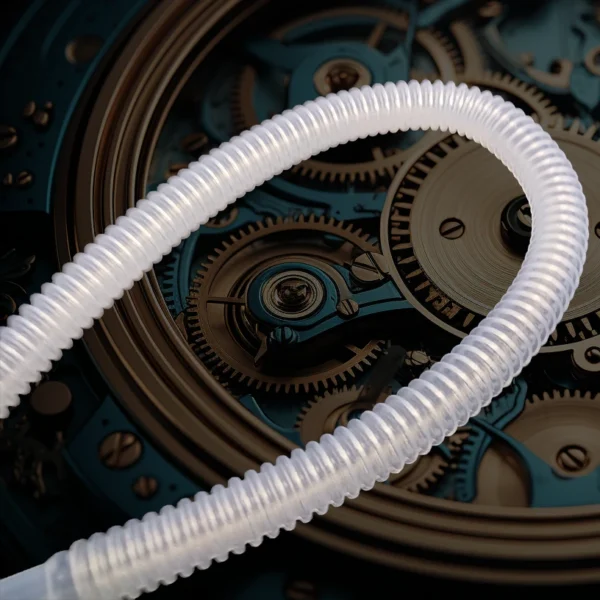

Custom Size Transparent PTFE Corrugated Pipe for High Pressure & Heat

This PTFE corrugated pipe offers exceptional chemical resistance and heat stability (-200°C to 260°C), ideal for high-pressure industrial applications. Its transparent design allows real-time monitoring, while custom sizes ensure precise compatibility. Perfect for chemical processing, oil & gas, and extreme temperature environments.