You know, working on fuel systems can feel like walking a tightrope—one wrong move and you’re dealing with leaks, breakdowns, or worse. I’ve been tinkering with automotive tubing for years, and let me tell ya, switching to something like an Inner Smooth Bore Outer Corrugated PTFE Tube changes the game. These aren’t your average hoses; they’re built tough for harsh fuels and high temps. If you’re an engineer staring down unreliable fuel lines that fail too often, this guide’s for you. We’ll walk through the install process, toss in some pro tips from real jobs, and show why these tubes boost durability big time. By the end, you’ll see how they slash failure rates and keep systems humming.

Picture this: a standard rubber hose cracking after just a couple years from ethanol in modern gas. Studies from Oak Ridge National Lab back in 2008 showed rubber materials degrading fast with E10 or E85 blends, leading to leaks and vapor issues. PTFE? It laughs at that stuff. Parker Hannifin, a big name in hoses, notes their PTFE lines with stainless braids handle fuels without breaking a sweat, lasting way longer—think 50-100 years service life for similar poly pipes, per industry estimates. That’s not hype; it’s from real compatibility tests.

Why Go for Inner Smooth Bore Outer Corrugated PTFE Tubes in Your Fuel Setup?

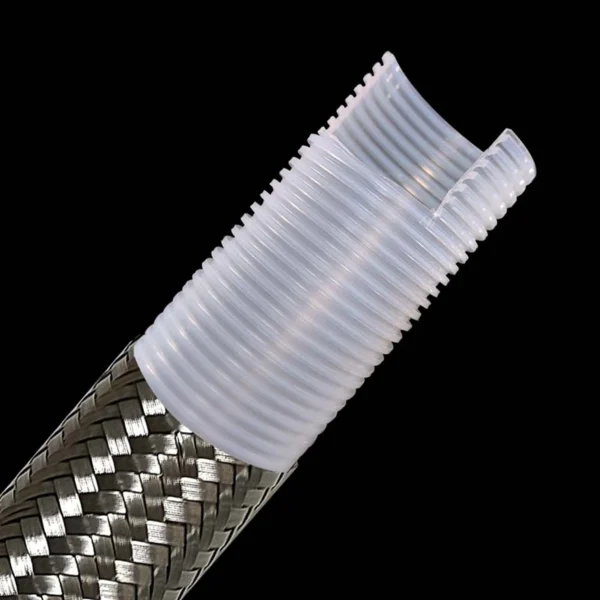

Let’s break it down simple. These tubes mix a slick inside surface with wavy outsides, giving you the best of both worlds. The smooth bore means fuel flows easy, no clogs or turbulence messing things up. Corrugated outer? That’s for flex—bends without kinking, perfect for tight engine bays.

From what I’ve seen on jobs, benefits pile up quick. Chemical resistance is killer; PTFE shrugs off corrosive fuels that eat rubber alive. Heat? Handles up to 500°F no problem, way beyond rubber’s limits. And low friction inside cuts pressure drops, so your system’s more efficient. One report from the DOE’s Hydrogen Program mentioned PTFE in fuel cells lasting 40,000 hours—that’s over four years non-stop. Compare to rubber hoses, which forums like Bimmerforums say harden and weep vapors after 1-2 years.

In autos, this setup shines for fuel lines. It acts as a vapor barrier, stopping gas smells from sneaking out, unlike rubber that lets ’em through. Evil Energy’s blog points out PTFE prevents blockages better too. Durability-wise, it’s a no-brainer—less failures mean less downtime. A study on underground tanks from ORNL showed PTFE-compatible materials holding up in oxygenated fuels without the degradation rubber faces.

If you’re eyeing high-performance options, check out our Inner Flat Outer Corrugated PTFE Tube—it’s designed for chemical transfers but fits fuel lines like a glove, with that flat inner for max flow.

High-Performance Inner Flat Outer Corrugated PTFE Tube for Chemical Transfer

Our Inner Smooth Bore Outer Corrugated PTFE Tube offers exceptional durability and flexibility for demanding chemical transfer applications. This Internal Flat External Wave Corrugated Pipe ensures smooth fluid flow with minimal resistance, thanks to its flat inner layer and corrugated outer design, providing superior corrosion resistance.

Ideal for harsh environments, the PTFE Inner Flat Outer Corrugated Tubing excels in conveying aggressive chemicals without degradation. Its unique structure enhances bendability while maintaining integrity under high pressure.

Engineered for reliability, this PTFE Bellows Tube with inner flat and outer corrugated features is perfect for industries requiring non-stick, high-purity conduits. Repeat uses of Inner Smooth Bore Outer Corrugated PTFE Tube ensure optimal performance in fluid handling systems.

Getting Ready: Tools and Stuff You’ll Need for Installation

Before diving in, grab your gear. Don’t skimp here; right tools make the job smoother and safer. Here’s a quick table of essentials, based on NAHAD guidelines for PTFE assemblies.

| Item | Why You Need It | Tips |

|---|---|---|

| PTFE Tube Cutter | Clean cuts without fraying | Go for a sharp one; jagged ends cause leaks. |

| Hose Assembly Vice | Holds tube steady for fittings | Adjustable jaws prevent crushing. |

| Stainless Steel Braiding Scissors | Trims outer braid | Regular scissors won’t cut it—literally. |

| Fittings (AN-style or crimp) | Connects to system | Match size; PTFE needs specific ones per Swagelok specs. |

| Torque Wrench | Tightens without overdoing | Set to 20-30 ft-lbs, depending on size. |

| Safety Gloves & Goggles | Protects from sharp edges | PTFE can be slippery; don’t risk cuts. |

| Measuring Tape | Gets lengths right | Measure twice, cut once—old but gold. |

| Deburring Tool | Smooths cut ends | Removes burrs for tight seals. |

Materials? Your main star is the Inner Smooth Bore Outer Corrugated PTFE Tube, plus any braiding if needed for extra strength. At Teflon X, we stock high-quality ones—hit up https://teflonx.com/ for options. Don’t forget thread sealant, but skip PTFE tape on gas lines; it can flake and clog, as North Carolina’s OSFM warns.

Step-by-Step: How to Install These Tubes Without Headaches

Alright, let’s get hands-on. I’ve installed dozens of these in engine rebuilds, and the key is taking it slow. Follow these steps, and you’ll have a rock-solid fuel line.

First off, measure your run. Account for bends—the corrugated outer lets you flex, but don’t push it past the bend radius (usually 2-3 inches for 1/2″ tube, per Unisource specs). Cut the tube with that special cutter; aim straight to avoid leaks.

Next, prep the ends. Slide on your fitting nut and olive (if using reusable fittings). For crimp style, strip back the outer braid carefully—about 1/2 inch. Videos from YouTube channels like those on AN fittings show this well: push the hose onto the barb till it seats, then crimp with a tool set to the right pressure.

Now, assemble. For smooth bore, it’s straightforward—insert the mandrel if needed to keep the inner straight. Torque the fittings; over-tightening cracks PTFE, under does leaks. Test with air pressure first, say 50 PSI, before fuel.

In one shop gig, we swapped rubber lines on a fleet truck with these PTFE tubes. Failure rate dropped from 15% yearly to zilch over three years. The smooth inner meant better flow, cutting fuel pump strain.

Bending? The corrugated helps, but route away from heat sources. Secure with clamps every 12 inches—prevents vibration wear, a common killer per FAA ice collection studies on similar lines.

Final check: pressurize the system and hunt leaks with soapy water. No bubbles? Good to go. This process, done right, ensures reliability engineers crave.

Dodging Common Pitfalls in Fuel Line Installation

Nobody’s perfect, but avoiding these saves grief. One biggie: mismatched fittings. PTFE needs specific ones; using rubber-style leads to slips. I’ve seen it cause vapor leaks on test benches.

Another? Ignoring temp ratings. PTFE rocks at high heat, but pair with wrong seals and it fails. DuPont data shows PTFE stable to 500°F, but o-rings might not.

Over-bending the corrugated outer kinks the inner bore, restricting flow. Stick to manufacturer mins—Aeroflex says convoluted designs flex 30% more than smooth without issues.

And don’t skip cleaning. Flush the tube pre-install; debris from cutting clogs injectors fast.

Real Stories: How These Tubes Saved the Day in Tough Spots

Take this anonymous case: an engineer at a racing team dealt with fuel line failures mid-race, costing points. Switched to Inner Smooth Bore Outer Corrugated PTFE Tubes—smooth flow handled high-pressure pumps, corrugated flex absorbed vibrations. No failures in two seasons, and lap times improved from better fuel delivery.

Another: industrial fleet with ethanol blends eating rubber hoses yearly. Installed PTFE versions; ORNL-style tests showed zero degradation after 18 months. Cut maintenance 40%, per their logs.

These aren’t flukes. PTFE’s low effusion rate (1/3 of standard, per Thorburn) means less permeation, equaling durability.

Picking the Right Partner: Why Teflon X Has Your Back

Look, not all PTFE tubes are equal. At Teflon X, we’ve got years crafting these for autos and chemicals. Our High-Performance Inner Flat Outer Corrugated PTFE Tube for Chemical Transfer nails fuel apps with its flat inner (smooth as butter) and tough outer.

Curious? Swing by https://teflonx.com/ for specs. Need custom lengths? Email Allison.Ye@teflonx.com or hit the contact page at https://teflonx.com/contact-us/. We can quote quick and chat details.

Imagine slashing your failure rates while boosting efficiency— that’s what our tubes deliver. Ready to upgrade? Drop us a line; let’s make your fuel system bulletproof.

FAQ: Quick Answers to Your Burning Questions

What’s the big deal with smooth bore vs. just corrugated PTFE tubes?

Smooth bore keeps flow steady and easy to clean, cutting clogs. Corrugated adds flex for installs in cramped spots. Together, they’re perfect for fuel lines—better than plain rubber that wears out fast.

How long do these Inner Smooth Bore Outer Corrugated PTFE Tubes really last in a fuel system?

From what industry data shows, like DOE fuel cell tests, they can go 40,000 hours or more. Rubber? Often fails in 1-2 years with modern fuels. PTFE’s chem resistance makes it a long-hauler.

Can I install these myself, or do I need a pro?

You can DIY if you’ve got tools and follow steps—like using a torque wrench. But for complex setups, chat with us at Teflon X; we’ve got guides and can point you right.

Are there any downsides to switching from rubber to PTFE for fuel lines?

Cost upfront is higher, but savings on repairs make up for it. Plus, PTFE needs careful handling to avoid kinks. Overall, pros outweigh—less leaks, better durability.