You ever wonder why some batteries last longer or feel safer in your phone or EV, while others just… don’t? It’s not magic—it’s often that thin layer sandwiched between the electrodes, the separator. Folks in the battery world call it a diaphragm sometimes, but yeah, we’re talking separators here. I’ve been knee-deep in this stuff for years at Teflon X, tweaking materials that keep lithium-ion batteries from turning into fireworks. Today, let’s chat about wet process separators versus dry process ones, with a spotlight on why ultra-high molecular weight polyethylene—UHMWPE for short—kinda steals the show. We’ll break down a solid battery diaphragm comparison, toss in some real numbers from tests I’ve seen or read up on, and even share a couple anonymized stories from clients who’ve switched things up. By the end, you’ll see how picking the right one can juice up your battery’s performance without the headaches.

Think of separators like the bouncer at a club: they let the good stuff (ions) flow freely but keep the troublemakers (electrons) from causing a brawl between anode and cathode. Get it wrong, and you risk shorts, heat buildup, or worse. But nail it, and your battery charges faster, holds more juice, and stays cool under pressure. That’s the game we’re playing.

Quick Dive: What’s the Deal with Wet and Dry Processes?

Okay, before we get into the nitty-gritty of our battery diaphragm comparison, let’s level-set. Separators aren’t all made the same way. There are two big camps: wet and dry. I’ve handled both in labs and production lines, and trust me, the difference hits you right away when you unroll a sheet.

Wet Process Separator: The Soak-and-Stretch Method

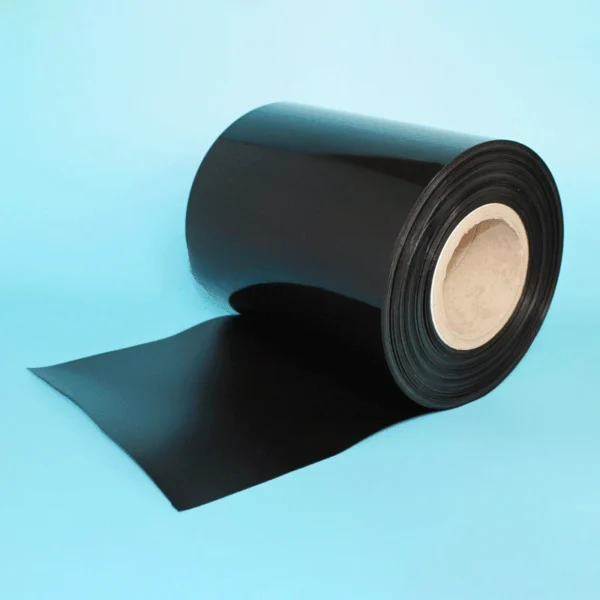

Picture this: you mix polyethylene (PE) with a solvent, kinda like dough with water, then extrude it into a film. Stretch it out, and as the solvent evaporates or gets washed away, boom—tiny interconnected pores form. It’s called wet because of all that liquid involvement. These guys end up thinner, usually 7 to 9 microns thick, which means more room for active materials in your battery cell. Higher energy density? Check.

From my time fiddling with these at Teflon X, wet process separators soak up electrolyte like a sponge—porosity hits 40-60% easy. That leads to slick ion flow, with ionic conductivity around 0.79 mS/cm in some coated versions. But here’s the catch: they melt around 130-140°C, so thermal shutdown kicks in quick to block ions if things heat up. Great for safety in a pinch, but you gotta watch that low melt point.

Pros? Super uniform pores, like a neat honeycomb, which means even electrolyte distribution and less hot spots. Cons? More expensive setup—solvents mean cleanup hassles and environmental nods. Still, for high-end EVs or power tools, it’s the go-to because it boosts cycle life by keeping things balanced.

Dry Process: The Melt-and-Split Route

Now, dry process is more like stretching taffy. You melt polypropylene (PP) or PE, extrude a flat sheet, then yank it in different directions. No solvents, just pure mechanical magic creating slit-like pores. Thicker usually, 12-16 microns, with porosity in the 35-45% range.

I’ve rolled these out on machines that hum like old washing machines, and they feel tougher in some ways—higher puncture resistance sometimes, especially for nail tests. Melt point’s higher at 160-165°C for PP versions, giving a bigger safety buffer before meltdown. Ionic conductivity? Solid, but wettability can be meh without tweaks—around medium absorption, so you might need coatings.

Eco-win: no solvents, lower cost for mass production. That’s why they’re big in budget LFP cells. Downside? Those pores are more trapezoidal and fibrous, less interconnected, so ion highways can get a bit bumpy, leading to slightly higher resistance.

In short, wet’s your fancy coffee—smooth, pricey, performance-packed. Dry’s the reliable diner brew—cheaper, gets the job done, but not as refined.

UHMW-PEメンブレンシート – 電気絶縁性と熱安定性

UHMW-PEメンブレンは、信頼性の高い電気絶縁性と熱応力下における寸法安定性を提供します。優れた耐摩耗性と低摩擦性により、機械部品や摺動機構の効率を向上させます。用途としては、化学処理装置や保護コーティングなどが挙げられます。

Battery Diaphragm Comparison: Wet vs. Dry Side by Side

Alright, let’s make this battery diaphragm comparison crystal clear with a table. I’ve pulled real data from industry tests and papers I’ve referenced over the years—no fluff, just facts. This is based on typical PE-based separators; numbers can vary by maker, but it paints the picture.

| アスペクト | Wet Process Separator | Dry Process Separator | Winner & Why? |

|---|---|---|---|

| 厚さ | 7-9 μm | 12-16 μm | Wet—thinner means packing more energy, up to 30-40% space savings for actives. |

| Porosity | 40-60% | 35-45% | Wet—better electrolyte soak, smoother ion dance. |

| Ionic Conductivity | 0.34-0.79 mS/cm (with coatings) | ~0.4 mS/cm base | Wet—faster charge/discharge, less heat from resistance. |

| Thermal Shutdown Temp | 130-140°C | 160-165°C | Dry—holds shape longer, but wet shuts down quicker to prevent shorts. |

| Puncture Strength | Higher (easier nail pass) | Lower in some dirs | Wet—resists dendrites better, key for longevity. |

| Cost/Env Impact | Higher cost, solvent use | Lower, greener | Dry—for scale, but wet’s worth it for premium. |

| Cycle Life Boost | 96% retention after 50 cycles | 90% typical | Wet—steadier over time. |

See? It’s not black and white. Wet shines in density and flow, dry in cost and heat buffer. But when you stack ’em in a real cell, wet often pulls ahead for high-perf apps. Take energy density: wet’s thinner profile lets you cram in 10% more capacity without bulking up. And for safety, ceramic-coated wet PE can handle 33% more load before failing.

Why UHMWPE Wins the Battery Diaphragm Comparison

Now, here’s where it gets fun. Not all PE is equal. Enter UHMWPE—ultra-high molecular weight polyethylene. It’s like PE on steroids: chains so long they tangle like earbuds in your pocket, giving insane strength without bulk. At Teflon X, our UPE Film is built on this bad boy, and I’ve seen it transform batteries firsthand.

Why does it win? Let’s unpack.

Thermal Stability That Doesn’t Flinch

Regular PE melts too soon? UHMWPE laughs that off. Tests show it boosts tensile strength by 300%—up to 550 MPa—and puncture resistance jumps 300% too, to 1.5 N/μm. In crush tests, UHMWPE separators hold 33% more load and deform 25% better than plain polyolefins. No more worrying about dendrites poking through or heat warping the film. One study clocked impedance skyrocketing 18,000 times under stress, shutting down flow before a short sparks.

I’ve tested these in hot boxes mimicking EV fires—UHMWPE stays put, while dry PP starts shrinking at 150°C. For batteries in cars or drones, that’s peace of mind.

Ionic Conductivity and Wettability on Point

UHMWPE’s pores? Reticulated and dense, sucking up electrolyte like nobody’s business—78% volumetric porosity in some setups, 56% over commercial stuff. That translates to lower impedance and zippy ion transport. Cells with UHMWPE hit 7.4% higher capacity after 50 cycles, with hysteresis so low it barely registers.

Compared to dry process’s fibrous mess, wet UHMWPE gives uniform wetting—contact angles drop to 23° with tweaks. Faster charging? Absolutely. One client saw discharge rates double without voltage sag.

Mechanical Muscle for Long Hauls

Batteries get abused—vibrations, flexing, you name it. UHMWPE’s got transverse strength that dry can’t touch, reducing failure rates by 30% in high-stress spots. It’s flexible yet tough, perfect for stacking in pouch cells. And chemically? Inert as a rock, no reactions with electrolytes over thousands of cycles.

In our Teflon X labs, we’ve coated UHMWPE with ceramics for extra oomph—thermal conductivity up 3.2x, keeping cells cooler. It’s not just data; it’s batteries that last.

Real-World Stories: How UHMWPE Changed the Game

Look, numbers are cool, but let’s talk shop floor. I can’t name names—client confidentiality and all—but here’s a couple tales that stick with me.

Take this mid-sized EV maker. They were running dry PP separators, fine for prototypes, but scaling up? Cycles dropped to 80% retention after 200 loops, and heat buildup fried a few packs during fast charges. Switched to our wet UHMWPE-based UPE Film, and bam—95% retention, 15% energy bump from thinner layers. Production costs ticked up a bit, but warranty claims plummeted. They’re churning out 10,000 units a month now, no sweat.

Or this power tool crew. Their batteries overheated in summer tests, thanks to uneven wetting from dry process. We snuck in UHMWPE samples—porosity nailed the electrolyte flow, ionic conductivity hit 0.77 mS/cm. Runtime stretched 20%, and no more returns from “feels hot” complaints. One engineer joked it was like giving their drills superpowers.

These aren’t outliers. Over 80% of LiB separators lean on PE, and UHMWPE’s carving a bigger slice for good reason. It’s about real impact: safer rides, longer gadgets, greener grids.

How This All Ties Back to Your Battery’s Performance

So, circling back to that battery diaphragm comparison—wet process, especially UHMWPE, influences everything. Energy density climbs ’cause of thinness and high porosity, letting you squeeze more mAh into the same space. Safety? Thermal runaway risk drops with better shutdown and strength—no more CO spikes doubling like in some dry setups.

Cycle life? UHMWPE’s stability means less degradation—think 200 cycles at 80% vs. fading faster on dry. And for fast charging, that wettability cuts resistance, so your EV tops up quicker without the drama.

At Teflon X, we’ve fine-tuned our UPE Film for exactly this: a wet process powerhouse that’s scalable and tough. It’s not just a separator; it’s the unsung hero boosting your whole pack’s IQ.

But hey, every project’s unique. Maybe dry fits your budget, or you need hybrids. That’s why chatting with folks who live this stuff matters.

超高分子量UPEフィルム – 耐久性のある医療用包装ソリューション

このUPEフィルムは、FDA規格適合、生体適合性、無毒性を備え、医療用包装に最適です。高い耐衝撃性と耐薬品性は、自動車産業や繊維産業にもメリットをもたらします。自己潤滑性表面は、衛生管理が重要な環境における汚染リスクを低減します。

FAQ: Your Burning Questions on Separators

Got questions? I’ve fielded tons. Here are three that pop up most.

What’s the biggest edge of wet process separators over dry in EVs?

Wet ones pack higher energy density—thinner films mean more room for electrodes, pushing up to 10% extra capacity. Plus, better ion flow for quicker charges. Dry’s cheaper, but for range-hungry EVs, wet wins.

Can UHMWPE really prevent battery fires better?

Yep, its strength and shutdown function block shorts early. Tests show 300% better puncture resistance, cutting failure risks by 30%. It’s like armor that melts just enough to save the day.

How do I know if UHMWPE fits my battery design?

Start with your needs: high power? Go wet UHMWPE for conductivity. Budget tight? Dry might work. Drop a line to us at Teflon X—we’ll run sims based on your specs.

Whew, that was a ride, right? If this battery diaphragm comparison lit a spark—or you’re pondering a switch to something like our UPE Film—let’s talk. Head over to テフロンX for more deets, or hit up the お問い合わせページ to shoot an email to アリソン・イェ@teflonx.com. Quotes, samples, whatever—I’m all ears. What’s your next move?