Alright, picture this: You’re knee-deep in a project, staring at a stack of hose specs that might as well be written in ancient runes. The boss is breathing down your neck for a quick decision on that PTFE lined hose, and one wrong pick could mean leaks, downtime, or worse—a total system meltdown. Sound familiar? I’ve been there, more times than I’d like to admit. Over the past 15 years hustling in industrial supply, I’ve helped folks from small shops to big chem plants dodge those bullets. And today, I’m laying it all out for you—no fluff, just the real deal on how to zero in on the right PTFE lined hose without second-guessing yourself.

We’re talking about those tough-as-nails hoses that handle the nasty stuff: corrosive acids, scorching temps, you name it. If you’re a buyer or that go-to engineer who’s gotta spec this out based on pressure ratings, heat thresholds, or what kinda fluid’s sloshing through, this guide’s your roadmap. By the end, you’ll have a clear framework to match your setup’s demands, plus some insider tips from jobs I’ve wrapped up myself. Let’s dive in and get you sorted.

What Makes a PTFE Lined Hose Such a Game-Changer?

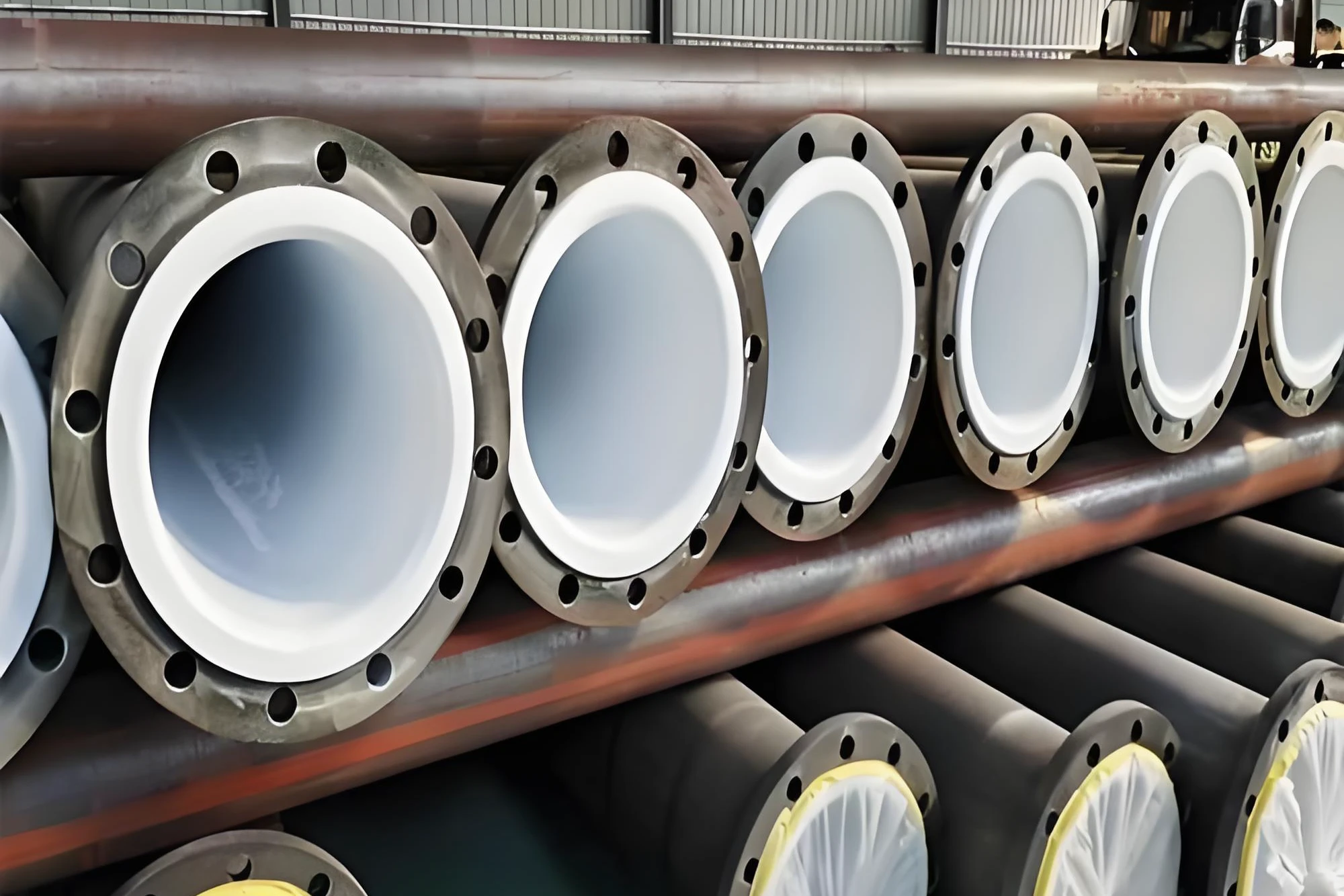

Before we jump into the steps, let’s level-set. A PTFE lined hose? It’s basically a rubber or thermoplastic outer jacket wrapped around a slick inner tube made from PTFE—that’s polytetrafluoroethylene, the stuff behind non-stick pans and a ton of high-tech gear. Why PTFE? It shrugs off chemicals like they’re nothing. According to specs from Danfoss PowerSource, these hoses can take temps from -54°C to 260°C without batting an eye, and they’re low-friction for smooth flow.

I’ve swapped out failing rubber hoses in breweries where beer lines got gummed up from pH swings—PTFE fixed that overnight. It’s not just durable; it’s versatile for everything from pharma transfers to automotive fuel lines. But here’s the kicker: Not all PTFE lined hoses are created equal. Skip the guesswork, and you’ll avoid those “oops” moments that cost real money.

스테인리스 스틸 브레이디드 PTFE 호스 - 냉각수용 정전기 방지 테플론 튜브

이것 스테인리스 스틸 브레이디드 PTFE 호스 냉각수 응용 분야에 완벽한 솔루션입니다. 정전 방지 브레이디드 튜브, 고온에 견디면서 정전 방전을 방지합니다. 신뢰할 수 있는 제품으로 사용하세요. 스테인리스 스틸 냉각수 호스 또는 엔진 냉각수 라인. 이것 전도성 편조관 오래 지속되도록 만들어졌습니다.

Step 1: Nail Down Your Pressure Requirements

First things first—pressure. If your system’s pushing high PSI, you can’t skimp here. Start by checking your pump specs or whatever’s driving the flow. Most industrial apps run 50-200 bar, but some hydraulic setups crank it to 400 bar or more.

Look, I once consulted on a food processing line where the buyer grabbed a hose rated for 100 bar thinking it’d cover their spikes. Boom—burst on day three. Lesson learned: Always build in a safety margin, like 1.5x your max expected pressure.

Here’s a quick table to eyeball common pressure ratings for PTFE lined hoses, pulled from real manufacturer data like what’s out there from Flextech Industries:

| 호스 유형 | Max Working Pressure (bar) | 파열 압력(바) | 가장 적합한 |

|---|---|---|---|

| Single Braid PTFE Lined | 150-250 | 600-1000 | General chem transfer |

| Double Braid PTFE Lined | 300-400 | 1200-1600 | High-pressure hydraulics |

| Convoluted PTFE Lined | 50-150 | 200-600 | Vacuum or flexible apps |

Source: Adapted from Flextech’s T6100 series specs, where working pressure hits 241 bar standard. Pro tip: For impulse services—like pumps that pulse—derate by about 1000 PSI, as Twin City Hose recommends in their PTFE brochure. That keeps things from fatiguing too quick.

Grab your system’s peak pressure, factor in surges, and match it. If you’re dealing with flares for easy connections, check out our PTFE Lined Hose with Flared Ends at Teflon X—they’re built for that extra reliability without the hassle.

Step 2: Temperature—Hot or Cold, It Gotta Hold

Temp’s a sneaky one. PTFE shines here, handling -70°C to +230°C in many builds, per UK-based Flexibles Ltd. data. But your outer braid or cover? That might cap out lower if it’s rubber-wrapped.

Think about your process: Is it steam cleaning at 150°C? Cryo storage dipping to -50°C? I’ve seen engineers overlook ambient swings in outdoor installs—hoses cracking from freeze-thaw cycles. Always ask: What’s the fluid temp, and what’s the environment doing?

Break it down like this under an H3 for clarity:

Matching Temp to Your Setup

- Low-Temp Apps: Go for virgin PTFE liners; they stay supple down to -200°C theoretically, but real-world’s around -65°F as Danfoss notes.

- High-Heat Scenarios: Double-check braid material—stainless steel holds up to 450°F without sagging.

- Cycling? If temps yo-yo, pick convoluted styles; they’re less prone to kinking.

In one gig I did for a distillery, we spec’d a PTFE lined hose for ethanol vapors hitting 180°C intermittent. Switched to a silicone-covered version for chafe resistance, and it’s been humming for three years straight. No drama.

Step 3: Media Compatibility—What’s Flowing Through?

This is where PTFE earns its keep: Chemical resistance that’s off the charts. It laughs at acids, bases, solvents—pretty much everything short of molten alkali metals. Tubes International’s BIOFLON line, for instance, uses virgin PTFE for zero contamination in pharma-grade transfers.

But don’t assume total immunity. Start with your SDS sheets for the media: pH, viscosity, abrasives? PTFE’s inert to 98% of chemicals at room temp, but at 200°C, some fluorides might nibble at it.

I’ve got a mental checklist from years of audits:

- Corrosive? PTFE’s your friend—beats rubber every time.

- Food-grade? Ensure FDA-compliant liners, no carbon black additives.

- Abrasive slurries? Add a conductive layer to zap static buildup.

Quick story: A client in paints was routing solvents that ate through their old PVC lines. We went with a smooth-bore PTFE lined hose, and output jumped 20% from better flow. No clogs, no spills.

Step 4: Sizing It Up—ID, OD, and Length

Size matters, folks. Too small, and you choke flow; too big, and it’s wasteful. Inner diameter (ID) ties to your volume needs—use the formula: Flow rate (GPM) = (ID in inches)^2 * velocity (ft/s) * 0.408. Aim for 5-10 ft/s to avoid turbulence.

Length? Measure end-to-end, add 10% flex. For custom runs, that’s where Custom PTFE Hose Assemblies come in handy at Teflon X—we tailor ’em to your blueprint.

Outer diameter affects routing—keep it under 2 inches for tight spaces. And bends? Minimum radius is 4x ID to dodge kinks.

Ends and Fittings: Why Flared Makes Life Easier

Connections can make or break it. Swaged, crimped, or threaded—pick based on your system’s vibe. But for leak-proof seals under pressure, nothing beats flared ends. A PTFE Lined Hose with Flared Ends gives that JIC 37-degree flare for quick, secure hookups without adapters.

I’ve retrofitted flared setups in auto plants where vibration was shredding threads. Result? Zero failures in 18 months. If your app’s got movement, flare it up.

Going Custom: When Stock Just Won’t Do

Off-the-shelf is fine for basics, but for wonky routes or exotic media, custom PTFE hose assemblies are the move. At Teflon X, we crank these out with your exact specs—length, ends, even anti-static tweaks.

One time, a biotech firm needed a 50-foot loop with sanitary tri-clamp ends for sterile fills. Stock? Nah. Custom? Delivered in two weeks, and they’re still using it for vaccine trials. Tailored means no compromises.

High Pressure PTFE Hose Flared Ends – For Demanding Hydraulic Jobs

Need a high pressure PTFE hose with flared ends? Our hoses excel in demanding hydraulic and pneumatic systems. This robust, high pressure PTFE hose offers unmatched safety and durability.

PTFE Lined Hose vs. The Competition: A No-Brainer Table

To drive it home, here’s how PTFE stacks against rubber or metal in key spots (data from AFTubes and Piping World guides):

| 특징 | PTFE Lined Hose | 고무 호스 | Metal Hose |

|---|---|---|---|

| Temp Range (°C) | -60 to +260 | -30 to +120 | -200 to +600 |

| Chem Resistance | Excellent (98% inert) | Fair (limited acids) | Good (but corrodes) |

| 유연성 | High (convoluted opt.) | 중간 | 낮은 |

| Cost per Foot (est.) | $15-50 | $5-20 | $20-100 |

| Lifespan (years) | 5-10+ | 2-5 | 10+ (if no corrosion) |

PTFE wins on balance for chem-heavy work. As Marshall Equip points out, it’s the go-to for industries like chem processing where downtime’s a killer.

Real Talk: Stories from the Field That’ll Make You Think Twice

Let’s get personal—I’ve got scars from bad picks. Take “Project Acid Wash”: A mid-size chem plant was sourcing hoses for sulfuric acid transfer. Buyer went cheap on a FEP-lined alternative. Three months in, delamination everywhere. We stepped in with PTFE lined hoses rated to 200 bar, full vacuum capable. Swapped ’em, and their throughput stabilized—no more emergency shutdowns. Saved ’em about $40k in lost production, I’d wager.

Or “Brew Blues”: Craft brewery fighting CO2 line freezes. Off-the-shelf rubber cracked at -20°C bursts. Custom PTFE assembly with insulated cover? Temps held steady, and their IPA’s flowing smoother than ever. These aren’t hypotheticals; they’re from my notebook, anonymized of course.

Seeing setups thrive like that? That’s why I do this. Your turn to avoid the pitfalls.

Common Pitfalls and How to Sidestep ‘Em

Even pros trip up. Overlooking static in flammable media? Add carbon black to the liner—prevents sparks, as per Titeflex’s ThermMaster specs. Ignoring certifications? Look for ISO 9001 or FDA stamps. And maintenance? Flush quarterly; it’ll extend life by 30%, from what I’ve tracked on installs.

Budget-wise, upfront cost stings, but ROI’s quick—fewer replacements mean real savings.

Wrapping This Up: Time to Make Your Move

Whew, we covered a lot—pressure maps, temp tricks, media matches, all the way to custom tweaks. Picking the right PTFE lined hose boils down to knowing your params cold and matching ’em smart. Do that, and you’re not just buying a part; you’re future-proofing your operation.

Feeling pumped to spec one out? Hit up the team at Teflon X—we’ve got the expertise to walk you through it. Swing by https://teflonx.com/ for more on our lineup, or drop a line to 앨리슨.예@테프론x.com for a no-obligation quote. Head to our 연락처 페이지 and let’s chat details. What’s your toughest challenge right now? I’m betting we can sort it.

Teflon X PTFE Lined Hose with Flared Ends – Smooth Bore Design

Our PTFE Lined Hose with Flared Ends ensures a pure, contamination-free fluid path. This high-purity PTFE lined hose is ideal for critical applications. Get reliable performance.

FAQ: Quick Hits on PTFE Lined Hoses

What’s the biggest mistake folks make when selecting a PTFE lined hose?

Rushing the pressure calc without surge factors. Always derate for safety—I’ve seen it bite too many times.

Can PTFE lined hoses handle full vacuum?

Yep, most convoluted ones do, down to -1 bar. Great for suction lines in tanks.

How do I know if I need a custom PTFE hose assembly?

If stock lengths or ends don’t fit your route, or if media’s super niche—custom’s cheaper than failures long-term.