Unmatched Reliability: PTFE Corrugated Fuel Hose for Aerospace Applications

In the demanding world of aerospace engineering, component failure is not an option. At 테프론 X, we engineer solutions that exceed industry standards. Our 항공우주용 PTFE 주름 연료 호스 is designed to provide safe, consistent, and efficient fuel transfer under the most extreme conditions imaginable. Whether for commercial aviation, military jets, or space exploration vehicles, our advanced 주름진 연료관 technology ensures mission-critical performance.

Why Choose Our PTFE Corrugated Fuel Hose?

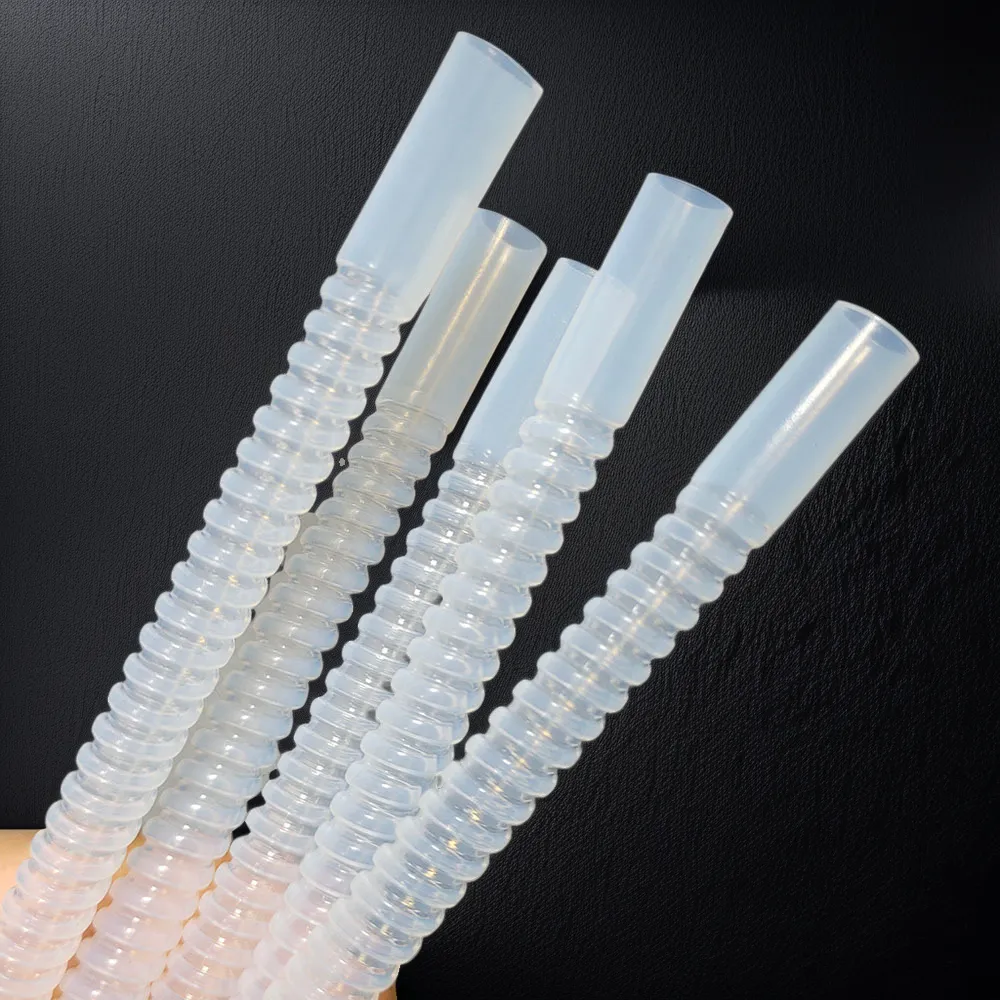

The core of our product lies in its premium construction. Unlike standard rubber hoses that degrade over time when exposed to aggressive aviation fuels, our 테프론 연료 호스 utilizes high-grade Polytetrafluoroethylene (PTFE). This material offers unparalleled chemical resistance, ensuring that the hose remains inert even when transporting highly corrosive jet fuels or hydraulic fluids.

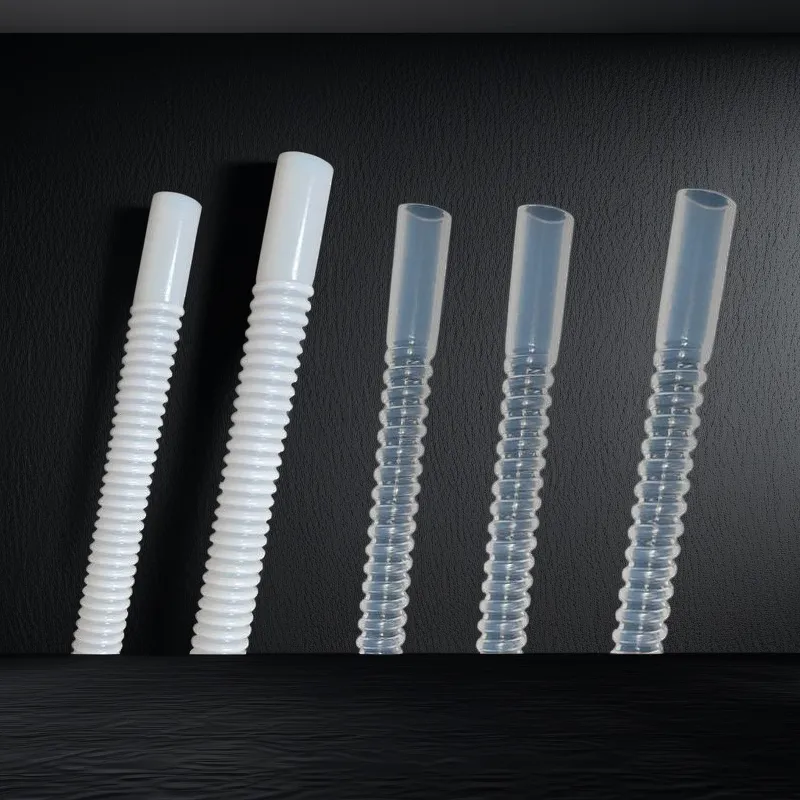

One of the standout features of this product is its flexibility. The unique convoluted design of our PTFE 골판지 연료 호스 allows for tight routing in confined spaces within aircraft fuselages and engine compartments. This flexibility also acts as a dampener, absorbing the intense vibrations typical of aerospace environments, thereby protecting sensitive connection points from stress fractures.

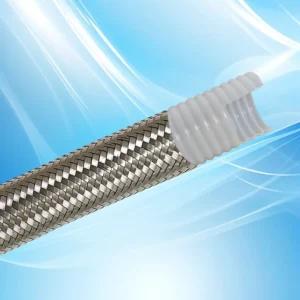

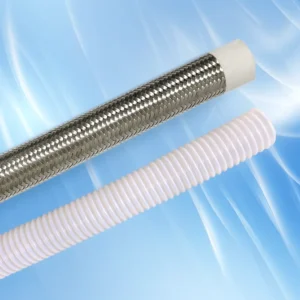

Durability is further enhanced by a robust reinforcement layer. While the inner core is a high-purity PTFE 연료 라인, the exterior is braided with high-tensile stainless steel (304 or 316 grade). This braiding protects the inner 주름진 연료관 from physical abrasion, cuts, and kinks while significantly increasing the pressure rating of the assembly.

주요 기능 및 이점

- Extreme Temperature Resistance: Capable of operating flawlessly in temperatures ranging from -80°C to +250°C, making it suitable for both cryogenic fuel systems and high-heat engine zones.

- 화학적 불활성: 그만큼 테프론 연료 호스 liner is impervious to almost all chemicals, fuels, and solvents, ensuring zero contamination of the fuel supply.

- 뛰어난 유연성: 그만큼 주름진 연료관 design offers a tighter bend radius compared to smooth-bore hoses without collapsing.

- High-Pressure Performance: Stainless steel reinforcement ensures the PTFE 연료 라인 can withstand high operational pressures and surge loads.

- Non-Aging Properties: Unlike rubber, PTFE does not age, crack, or harden over time, offering a virtually unlimited shelf life and reduced maintenance intervals.

기술 사양

우리의 PTFE 주름 연료 호스 is manufactured to meet rigorous aerospace standards. Below are the general specifications for our standard series. Custom sizes and braiding options are available upon request.

| 매개변수 | 사양 세부 정보 |

|---|---|

| Inner Material | Virgin or Anti-static (Conductive) PTFE (Corrugated) |

| 외부 보강 | Single or Double Stainless Steel Braid (SS304/SS316) |

| 온도 범위 | -80°C to +250°C (-112°F to +482°F) |

| 작동 압력 | Up to 3000 PSI (depending on diameter and braid) |

| 파열 압력 | 4:1 Safety Factor (4x Working Pressure) |

| Available Sizes (ID) | 1/4″ (6mm) to 4″ (100mm) |

| Vacuum Resistance | Full Vacuum (sizes up to 1″) |

| 피팅 | JIC, NPT, BSP, Flanges (Customizable) |

Applications in Aerospace

그만큼 PTFE 연료 라인 solutions provided by Teflon X are versatile. They are essential components in:

- Main engine fuel feed lines

- Auxiliary Power Unit (APU) fuel supply

- Hydraulic actuation systems

- Cooling systems requiring temperature-resistant hoses

- Instrumentation lines

Quality Assurance and Contact

~에 테프론 X, quality is our promise. Every PTFE 골판지 연료 호스 undergoes rigorous hydrostatic pressure testing and visual inspection before leaving our facility. We understand that in aerospace, safety is paramount.

Are you looking for a custom solution or need technical data regarding a specific 주름진 연료관 diameter? Our engineering team is ready to assist you in selecting the perfect 테프론 연료 호스 for your project.

For more information, please visit our website at 테프론x.com. To request a quote or discuss your requirements, please visit our 연락처 페이지 or email our sales team directly at allison.ye@teflonx.com.

상품평

아직 상품평이 없습니다.