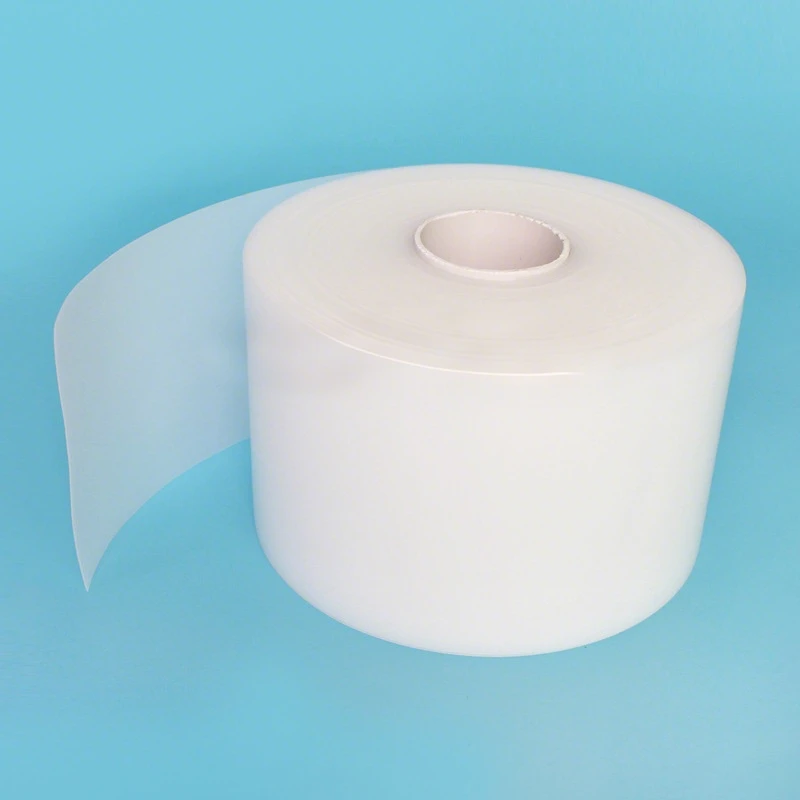

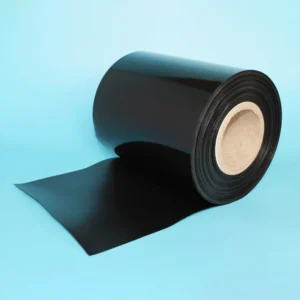

제품 개요

Unlock superior reliability in demanding electrical and thermal environments with Teflon X’s UHMW-PE Membrane Sheet, a high-performance Ultra-High Molecular Weight Polyethylene (UHMWPE) solution engineered for precision and endurance. This advanced UHMW-PE Membrane excels in providing robust electrical insulation, preventing breakdowns in high-voltage applications, while offering exceptional dimensional stability under thermal stress. With its superior wear resistance—up to 15 times that of carbon steel—and ultra-low friction properties, our UHMW-PE Membrane Sheet enhances efficiency in machinery parts, sliding mechanisms, and protective systems.

테프론 X UHMW-PE Membrane is chemically inert, resisting corrosion from acids, alkalis, and solvents (except oxidizing acids), and maintains self-lubricating performance to minimize maintenance. Ideal for chemical processing equipment and beyond, this non-toxic, low-moisture-absorbing material ensures long-term durability from -200°C to +80°C. As a versatile UHMW-PE Membrane, it supports innovation across industries—discover its potential at 테프론x.com.

주요 기능 및 이점

Crafted from premium UHMWPE with molecular weights over 3,000,000 g/mol, Teflon X’s UHMW-PE Membrane Sheet delivers these essential attributes for electrical, thermal, and mechanical excellence:

- 전기 절연: High dielectric strength safeguards against electrical failures in wiring, cables, and insulating barriers, with low conductivity for safe, reliable performance.

- 열 안정성: Maintains dimensional integrity and low thermal expansion under heat stress, operating seamlessly from cryogenic lows to elevated temperatures without warping or degradation.

- Superior Wear Resistance: 15× more abrasion-resistant than carbon steel, extending lifespan in high-friction zones like gears, guides, and conveyor components.

- 낮은 마찰 계수: Self-lubricating surface (0.05–0.15 dynamic) reduces energy loss, noise, and wear in sliding mechanisms, eliminating the need for external lubricants.

- 내화학성: Inert to corrosive substances, moisture, and most chemicals, ensuring stability in harsh processing environments with minimal absorption (<0.01%).

- Impact and Toughness: Unmatched among thermoplastics, with no-break Izod impact for shock absorption in dynamic machinery and protective applications.

- Lightweight and Versatile: Low density (0.93 g/cm³) for easy handling, available in sheet or microporous formats for customized UHMW-PE Membrane uses in filtration or coatings.

- Eco-Friendly Compliance: Non-toxic, odorless, and recyclable, meeting FDA standards for hygienic applications while promoting sustainability.

이것 UHMW-PE Membrane outperforms traditional insulators and liners, combining electrical safety with mechanical resilience for cost-effective, high-efficiency solutions.

응용 프로그램

테프론 X UHMW-PE Membrane Sheet is engineered for critical roles where electrical insulation, thermal stability, and durability converge, powering efficiency in varied sectors:

- Chemical Processing Equipment: Linings for pipes, tanks, valves, and pumps, leveraging chemical resistance and wear protection to handle corrosive flows and abrasives.

- Electrical and Electronics: Insulating sheets for cables, transformers, and circuit boards, providing dielectric barriers and thermal management in high-voltage systems.

- Machinery Parts and Sliding Mechanisms: Guide rails, bushings, and wear strips in automation, reducing friction and extending service life in industrial assembly lines.

- Protective Coatings: Anti-abrasion overlays for chutes, hoppers, and truck beds, ensuring smooth material flow and corrosion resistance in mining and logistics.

- Filtration and Separation: Microporous UHMW-PE Membrane variants for chemical filters and gas separators, offering high permeability with structural integrity.

- Aerospace and Automotive: Thermal-stable components like seals and insulators, benefiting from low weight, impact resistance, and low-friction performance.

From safeguarding chemical plants to optimizing machinery, our UHMW-PE Membrane Sheet delivers proven results in wear-prone, electrically sensitive environments.

기술 사양

Below is a comprehensive table of standard parameters for Teflon X’s UHMW-PE Membrane Sheet. Tailored specifications, including enhanced porosity or thickness, are available—contact us for custom UHMW-PE Membrane designs.

| 재산 | Value/Range | Test Standard/Notes |

|---|---|---|

| Material Type | Ultra-High Molecular Weight Polyethylene (UHMWPE) | ASTM D4020 |

| Molecular Weight | >3,000,000 g/mol | Gel Permeation Chromatography |

| 밀도 | 0.93 g/cm³ | ASTM D792 |

| Tensile Yield Strength | 19.3–23 MPa | ASTM D638 |

| 휴식 시 신장 | >300% | ASTM D638 |

| Shore D Hardness | 60–65 | ASTM D2240 |

| Impact Strength (Izod) | No Break (Unnotched) | Highest among thermoplastics |

| 마찰 계수 | 0.05–0.15 (Dynamic) | Comparable to PTFE |

| 내마모성 | 15x Carbon Steel | Taber Abrasion Test |

| 작동 온도 | -200°C to +80°C | Continuous Use |

| 내화학성 | Excellent (Acids, Alkalis, Solvents) | Except Oxidizing Acids |

| 물 흡수 | <0.01% (24 hrs) | ASTM D570 |

| 두께 | 0.1–5 mm | Customizable |

| 너비 | Up to 2 m | Roll or Sheet Format |

| FDA 규정 준수 | Yes (Non-Toxic, Food Contact Safe) | 21 CFR 177.1520 |

| Porosity (Microporous) | 30–70% (Optional) | For Filtration Grades |

| 유전 강도 | 20–30 kV/mm | ASTM D149 (Estimated for Sheets) |

Note: Values are typical and may vary based on processing and grade. For detailed datasheets, visit 테프론x.com.

왜 테프론 X를 선택해야 하나요?

Teflon X pioneers advanced polymer technologies, offering elite UHMW-PE Membrane Sheet solutions with uncompromising quality and adaptability. Our UHMW-PE Membrane integrates electrical insulation and thermal stability with unmatched wear resistance, streamlining your operations and reducing costs. Supported by expert guidance and global logistics, we empower your success in chemical and industrial innovation.

Secure the advantages of Teflon X’s durable UHMW-PE Membrane—peruse our catalog at 테프론x.com or engage via our 문의하기 페이지. Direct inquiries to 앨리슨.예@테프론x.com for swift assistance.

상품평

아직 상품평이 없습니다.