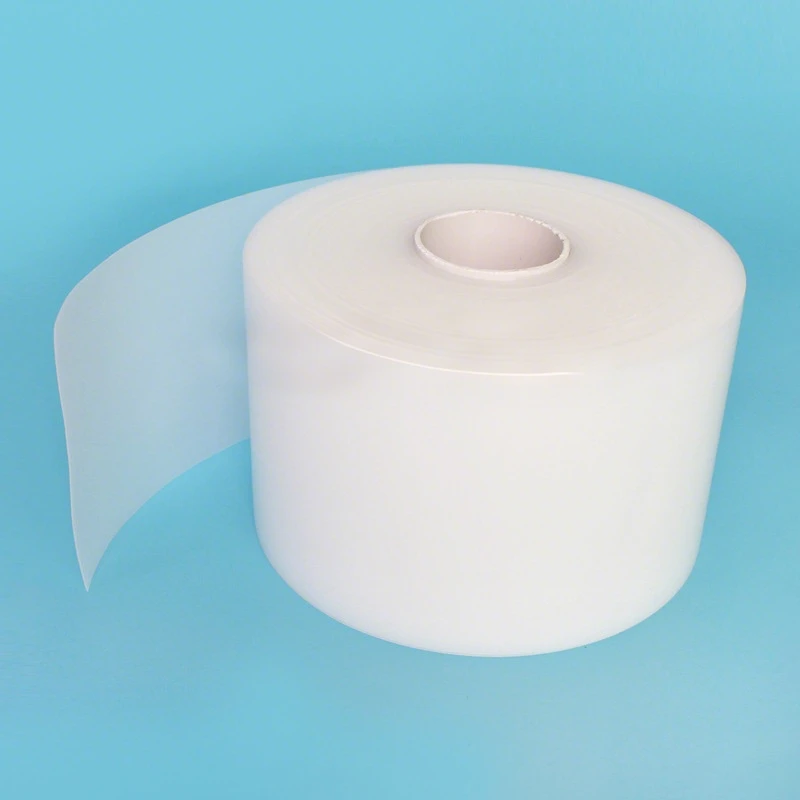

제품 개요

Engineered for the toughest environments, Teflon X’s UPE Film delivers unmatched performance as a premier Ultra-High Molecular Weight Polyethylene (UHMWPE) solution. This advanced UPE Film features non-adhesive surfaces that prevent material buildup and sticking, ensuring smooth operations in high-wear scenarios. Retaining exceptional ductility even at liquid nitrogen temperatures (-196°C), our UPE Film maintains flexibility and toughness without brittleness, making it ideal for cryogenic and extreme low-temperature applications.

With superior chemical resistance and thermal stability, Teflon X’s UPE Film excels in industrial linings, filtration systems, and automotive components, where reliability under stress is paramount. FDA-compliant and hygienic, this non-toxic UPE Film supports medical settings while reducing friction and extending service life. Molecular weight over 3,000,000 g/mol provides inherent self-lubrication and abrasion resistance that surpasses traditional materials. Discover how our UPE Film can safeguard your equipment—explore more at 테프론x.com.

주요 기능 및 이점

테프론 X UPE Film is crafted from high-performance UHMWPE, offering these critical advantages for demanding industrial use:

- Non-Adhesive Surface: Low surface energy prevents adhesion of materials, dirt, or residues, simplifying cleaning and maintenance in processing lines.

- Low-Temperature Flexibility: Ductile down to -200°C, retaining impact strength and preventing cracking in cryogenic storage or cold-chain logistics.

- Exceptional Wear Resistance: Outperforms steel in abrasion tests, ideal for high-friction linings in chutes, hoppers, and conveyors.

- Chemical and Corrosion Resistance: Inert to acids, alkalis, solvents, and moisture, ensuring longevity in harsh chemical environments.

- Self-Lubricating Properties: Ultra-low coefficient of friction (0.05–0.15) reduces energy loss and noise in moving parts like guides and slides.

- 열 안정성: Operates reliably from cryogenic lows to +80°C, with minimal thermal expansion for precise applications.

- Hygienic and Biocompatible: FDA-approved, odorless, and non-toxic, perfect for food processing, medical packaging, and sterile environments.

- Versatile Customization: Available in thin films for linings or microporous variants for enhanced filtration and breathability.

This robust UPE Film combines the best of polyethylene engineering, providing a lightweight, cost-effective alternative to metals and elastomers for superior durability.

응용 프로그램

테프론 X UPE Film is the preferred choice for protecting and enhancing performance in diverse sectors, thanks to its non-adhesive and flexible properties:

- Industrial Linings: Chute, hopper, and tank liners to combat abrasion, sticking, and corrosion in mining, agriculture, and bulk material handling.

- Filtration Systems: Microporous UPE Film for water treatment, gas separation, and chemical processing, offering high permeability and chemical inertness.

- Automotive Components: Weather stripping, bushings, and protective films for reduced friction, noise reduction, and impact resistance in vehicles.

- Medical and Hygiene: Sterile packaging, implant coatings, and medical device linings, leveraging FDA compliance for safe, clean contact.

- Cryogenic and Cold Storage: Seals and barriers in liquid nitrogen systems, retaining flexibility for aerospace and scientific applications.

- General Manufacturing: Conveyor guides, drawer slides, and machine guards to minimize wear and facilitate smooth material flow.

Whether lining industrial equipment or enabling precise filtration, our UPE Film ensures efficiency and longevity in every deployment.

기술 사양

Below is a comprehensive table of standard parameters for Teflon X’s UPE Film. Custom options, including specialized thicknesses and widths, are available—contact us for bespoke UPE Film solutions.

| 재산 | Value/Range | Test Standard/Notes |

|---|---|---|

| Material Type | Ultra-High Molecular Weight Polyethylene (UHMWPE) | ASTM D4020 |

| Molecular Weight | >3,000,000 g/mol | Gel Permeation Chromatography |

| 밀도 | 0.93 g/cm³ | ASTM D792 |

| Tensile Yield Strength | 19.3–23 MPa | ASTM D638 |

| Elongation at Break | >300% | ASTM D638 |

| Shore D Hardness | 60–65 | ASTM D2240 |

| Impact Strength (Izod) | No Break (Unnotched) | Highest among thermoplastics |

| 마찰 계수 | 0.05–0.15 (Dynamic) | Comparable to PTFE |

| 내마모성 | Exceeds Carbon Steel | Taber Abrasion Test |

| Operating Temperature | -200°C to +80°C | Continuous Use, Ductile at -196°C |

| 내화학성 | Excellent (Acids, Alkalis, Solvents) | Except Oxidizing Acids |

| 물 흡수 | <0.01% (24 hrs) | ASTM D570 |

| 두께 | 0.025–1.5 mm | Customizable, Skived Film |

| 너비 | Up to 2 m | Roll or Sheet Format |

| FDA 규정 준수 | Yes (Non-Toxic, Food Contact Safe) | 21 CFR 177.1520 |

| Porosity (Microporous) | 30–70% (Optional) | For Filtration Grades |

Note: Values are typical and may vary based on processing and grade. For detailed datasheets, visit 테프론x.com.

왜 테프론 X를 선택해야 하나요?

Teflon X is at the forefront of polymer innovation, delivering premium UPE Film with rigorous testing and customization to meet your exact needs. Our non-adhesive, low-temperature flexible UPE Film integrates seamlessly, reducing downtime and costs while upholding the highest safety standards. Backed by global supply chains and technical expertise, we’re your reliable source for transformative materials.

Elevate your industrial linings and beyond with Teflon X’s versatile UPE Film—view our full range at 테프론x.com or submit inquiries through our 문의하기 페이지. Reach 앨리슨.예@테프론x.com for personalized support.

상품평

아직 상품평이 없습니다.