When a driver slams on the brakes at 70 mph because a deer decided to cross the highway, they aren’t thinking about the chemical composition of the hose transfering hydraulic fluid to their calipers.

But you do. As an aftermarket brand or performance shop owner, you obsess over this stuff. And you should.

I’ve been in the fluid transfer game for years, and if there’s one debate that never seems to die, it’s the battle between traditional rubber hoses and the PTFE brake hose. If you are sourcing parts for a performance line or looking to reduce warranty claims on your private label products, understanding the gritty engineering details between these two is non-negotiable.

We aren’t just talking about “feeling” a difference. We are talking about physics, volumetric expansion, and strict DOT compliance.

The Problem with Traditional Rubber (It’s Not Just Age)

Most OEM cars roll off the lot with EPDM (Ethylene Propylene Diene Monomer) rubber hoses. They are cheap, they work fine for Grandma’s grocery getter, and manufacturers love them because they keep costs down.

But here is the issue: Rubber is a sponge. Not literally, but functionally.

Over time, rubber suffers from permeation. Moisture from the atmosphere seeps through the rubber wall and gets into the brake fluid. Since DOT 3 and DOT 4 fluids are hygroscopic (they love water), this is a recipe for disaster. Water lowers the boiling point of your fluid.

식품 가공용 유연한 PTFE 내부 평면 외부 골판지 튜빙

당사의 유연한 PTFE 내부 평면 외부 골판지 튜브는 세척이 용이하도록 매끄러운 내부 층과 식품 가공 라인의 유연성을 위해 골판지 외부 층으로 설계되었습니다. 이 매끄러운 내부 보어 외부 골판지 PTFE 튜브는 FDA 규정을 준수하는 무독성 식품 및 음료 이송을 보장합니다.

점성 물질을 운반하는 데 적합한 PTFE 벨로우즈 튜브는 향미 오염을 방지하고 잦은 세척에도 잘 견딥니다.

이 내부 평면 외부 파형 골판지 파이프를 귀하의 설비에 통합하세요. PTFE 내부 평면 외부 골판지 튜빙 구조는 위생과 내구성을 보장합니다.

The “Mushy Pedal” Physics

When you press the brake pedal, you are generating hydraulic pressure. Let’s look at a simplified formula for Pressure (P):

P = F / A

Where:

- P is Pressure

- F is the Force applied

- 에이 is the Area

In a perfect world, all that pressure moves the caliper piston. But rubber hoses have a high volumetric expansion rate. When the pressure spikes, the hose walls balloon out.

Instead of that force squeezing the rotor, it’s wasted expanding the hose. This is what drivers call “brake fade” or a “spongy pedal.” It gets worse as the rubber ages and loses its structural integrity. I’ve seen 5-year-old rubber hoses that look fine on the outside but swell like a balloon animal under hard braking.

Why PTFE is the Superior Choice for Performance

So, why are we seeing a massive shift toward 테프론 X style solutions in the aftermarket? It comes down to the molecule.

PTFE (Polytetrafluoroethylene) is basically the superhero of materials. The Carbon-Fluorine bond is one of the strongest in organic chemistry. It doesn’t react with brake fluid. It doesn’t rot from ozone exposure. And most importantly for your customers, it doesn’t stretch.

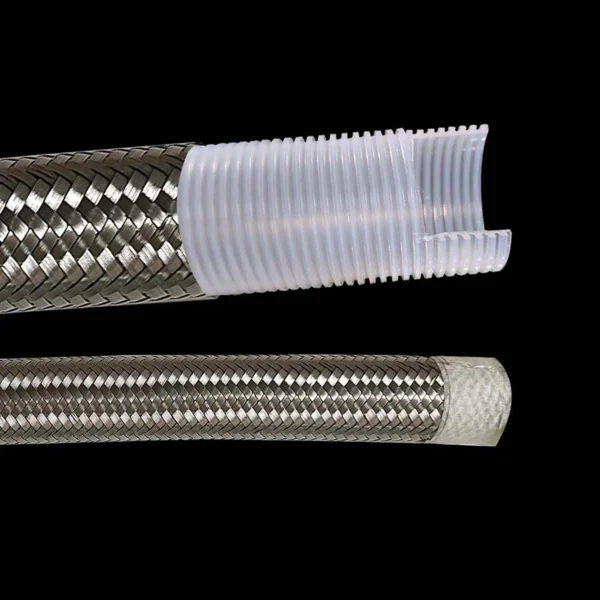

The Stainless Steel Braided Factor

A raw PTFE tube is great, but it needs armor. That’s where the stainless steel braided hose design comes in. We wrap the PTFE core in 304 or 316 stainless steel wire.

This does two things:

- Physical Protection: It stops road debris from nicking the line.

- Pressure Containment: It mechanically prevents the PTFE from expanding.

When you swap rubber for a braided PTFE line, you are essentially reducing the volumetric expansion to near zero. The driver feels immediate feedback. It’s not just marketing fluff; it is measurable fluid dynamics.

Deep Dive: DOT Compliance and Safety Standards

If you are selling parts in the US, you can’t ignore the Department of Transportation (DOT). Specifically, FMVSS 106.

I talk to a lot of startup brands who think they can just buy generic hose off Alibaba, crimp some fittings, and sell it. Do not do this.

DOT compliance isn’t a sticker you buy; it’s a rigorous testing protocol. To be street legal, a brake hose assembly must pass FMVSS 106 standards, which include:

- Whip Test: The hose is flexed and vibrated for roughly 35 hours while pressurized. It mimics years of suspension travel.

- Burst Strength: The hose must withstand pressures well above 4,000 psi (though we test much higher at 테프론 X).

- 인장 강도: You have to pull the fitting away from the hose with significant force to ensure the crimp holds.

Rubber hoses struggle to maintain these standards as they age. A PTFE hose, assuming the crimp is good, will pass these tests on day 1 and day 1,000 with almost identical results. That consistency is what you are selling to your B2B clients.

PTFE 벨로우즈 튜브: 제약용 내부 평면 외부 골판지

내부는 평평하고 외부는 주름진 PTFE 벨로우즈 튜브로, 제약 산업에 위생적이고 오염 없는 성능을 제공합니다. 내부는 매끈한 보어에 외부는 주름진 PTFE 튜브로, 제품 이송을 원활하게 하고 강력한 살균제에도 강합니다.

멸균 환경에 적합한 내부 평면 외부 웨이브 골판지 파이프는 약물 제조 공정에서 순도를 유지하며, 강도를 떨어뜨리지 않으면서도 유연성을 제공합니다.

효율성을 높이기 위해 PTFE 내부 평면 외부 골판지 튜빙을 선택하세요. PTFE 내부 평면 외부 골판지 파이프와 유사한 벨로우즈와 같은 구조로 엄격한 산업 표준을 준수합니다.

Technical Comparison: PTFE vs. Rubber

I put together this table to break down the differences. If you are building a pitch deck for a distributor, feel free to use this data.

| 특징 | EPDM Rubber Hose | PTFE (Teflon) Braided Hose |

|---|---|---|

| Core Material | Ethylene Propylene Diene Monomer | Polytetrafluoroethylene |

| Expansion Rate | High (Increases with age) | Negligible (Constant) |

| Fluid Compatibility | DOT 3, 4, 5.1 | All fluids (including DOT 5 Silicone) |

| 온도 범위 | -40°F to +250°F | -94°F to +500°F |

| 내마모성 | Low (requires rubber bumpers) | High (Stainless braid protection) |

| Typical Lifespan | 4-6 Years | Lifetime of the vehicle |

| 비용 | 낮은 | 중간~높음 |

You see the temperature range? That matters. If your customer is tracking their car, rotor temps can soar, radiating heat to the lines. Rubber gets soft when hot. PTFE doesn’t care.

Case Study: The “Soft Pedal” Fix

Let me share a quick story (names changed to protect the client). We had a performance shop, let’s call them “Apex Tuners,” reach out to us. They were building a line of big brake kits for the Subaru WRX platform.

They had amazing calipers and rotors, but they were packaging them with standard rubber lines to save $15 per kit.

The feedback was terrible. Customers complained that despite the expensive calipers, the pedal felt “mushy.”

Apex Tuners came to 테프론 X. We engineered a custom PTFE brake hose kit with a smoke-black PVC cover (to protect the braid and look cool).

The Result:

- Pedal firmness increased by roughly 30% (subjective driver feedback).

- Warranty claims regarding leaks dropped to zero over 12 months.

- They were able to market the “Stainless Steel Lines Included” as a premium upsell feature.

It turns out, the hose was the weakest link in their $2,000 braking system. Don’t let a cheap hose ruin your premium product.

Manufacturing: What Goes Into a Teflon X Hose?

We don’t just buy hose; we engineer solutions. Whether it is brake line durability or industrial applications, the process matters.

At our facility, we focus on:

- 버진 PTFE: We don’t use regrind. Regrind introduces impurities that can lead to microscopic stress cracks.

- Controlled Braiding: The tension on the stainless steel strands must be uniform. If one strand is loose, it creates a weak point where the inner liner can herniate.

- 100% Pressure Testing: Every single assembly that leaves the line gets pressure tested. No sampling. 100%.

While we are discussing different hose types, it is worth noting that we also specialize in other fluid transfer solutions. For applications requiring extreme flexibility (like fuel return lines or complex routing), you might look at our PTFE 골판지 호스. While not typically used for high-pressure braking, understanding the difference between smooth bore (for brakes) and corrugated (for flexibility) shows you know your stuff.

The Economics of Durability

Sure, PTFE costs more upfront. But calculate the TCO (Total Cost of Ownership).

If a rubber hose fails, you have towing costs, repair labor, brake fluid flushes, and potential bodywork damage. A PTFE hose is a “install it and forget it” component. For your brand, this means brand loyalty. Customers trust parts that don’t fail.

산업 기계용 주름 연료 튜브

PTFE 주름 연료 호스로 제작된 주름 연료 튜브는 EMI 차폐 및 열 안정성을 갖춰 산업 장비를 지원합니다. 테플론 연료 호스 구조는 극한의 온도와 화학 물질에 대한 내성을 갖추고 있습니다. 유연한 설계는 정렬 불량을 보정하여 유지 보수가 용이하고 수명이 연장됩니다.

How to Choose the Right OEM Partner

If you are looking for a manufacturer, ask them these questions:

- “Can you provide the DOT registration number?”

- “What is the burst pressure rating of your -3 AN line?”

- “Do you use 304 or 316 stainless?” (304 is fine for most, 316 is better for marine/salted roads).

If they hesitate, run.

At Teflon X, we are open about our specs. We know that brake line durability isn’t just about passing a test; it’s about keeping a family safe in their minivan or a racer safe at 150 mph.

FAQ: Common Questions About PTFE Brake Lines

Q: Are PTFE brake hoses street legal?

A: Yes, provided they are manufactured to FMVSS 106 standards and assembled by a registered manufacturer. A generic DIY line made in a garage is technically not street legal for highway use. Always look for the DOT stamp on the fitting or hose.

Q: Do stainless steel braided hoses need to be replaced?

A: Unlike rubber, which has a shelf life, PTFE doesn’t degrade from age. However, you should inspect them regularly. If the stainless braid is frayed from rubbing against a shock absorber, the hose is compromised and must be replaced immediately.

Q: Will switching to PTFE make my brakes stop the car faster?

A: technically, the friction stops the car. However, PTFE lines reduce the reaction time. By eliminating hose expansion, the time between your foot hitting the pedal and the caliper clamping the rotor is reduced. This can shave precious feet off your stopping distance during panic braking.

고압 테프론 브레이드 호스 - 산업용 PTFE 라이닝 플렉시블 호스

이것 PTFE 라이닝 플렉서블 호스 300°C의 단기간 노출 및 극저온 조건을 견뎌냅니다. 꼬불꼬불한 호스 진동 응력을 완화하는 설계로 유압 시스템, 연료 라인 및 용융염 이송에 적합합니다. 논스틱 표면은 오염을 줄이고, 반투명 옵션은 유량 모니터링을 가능하게 합니다.

Ready to Upgrade Your Product Line?

Look, the automotive market is crowded. To stand out, you need to offer quality that people can feel the second they touch the pedal.

If you are tired of dealing with inconsistent rubber hoses or want to launch a private label stainless steel braided hose line that meets strict DOT compliance, we need to talk.

Don’t settle for “good enough” when safety is on the line.

Contact Teflon X today. Let’s engineer a solution that fits your brand and your budget.

- Email me directly: 앨리슨.예@테프론x.com

- Get a Quote: 문의하기