Introduction to High-Performance Fluid Transfer

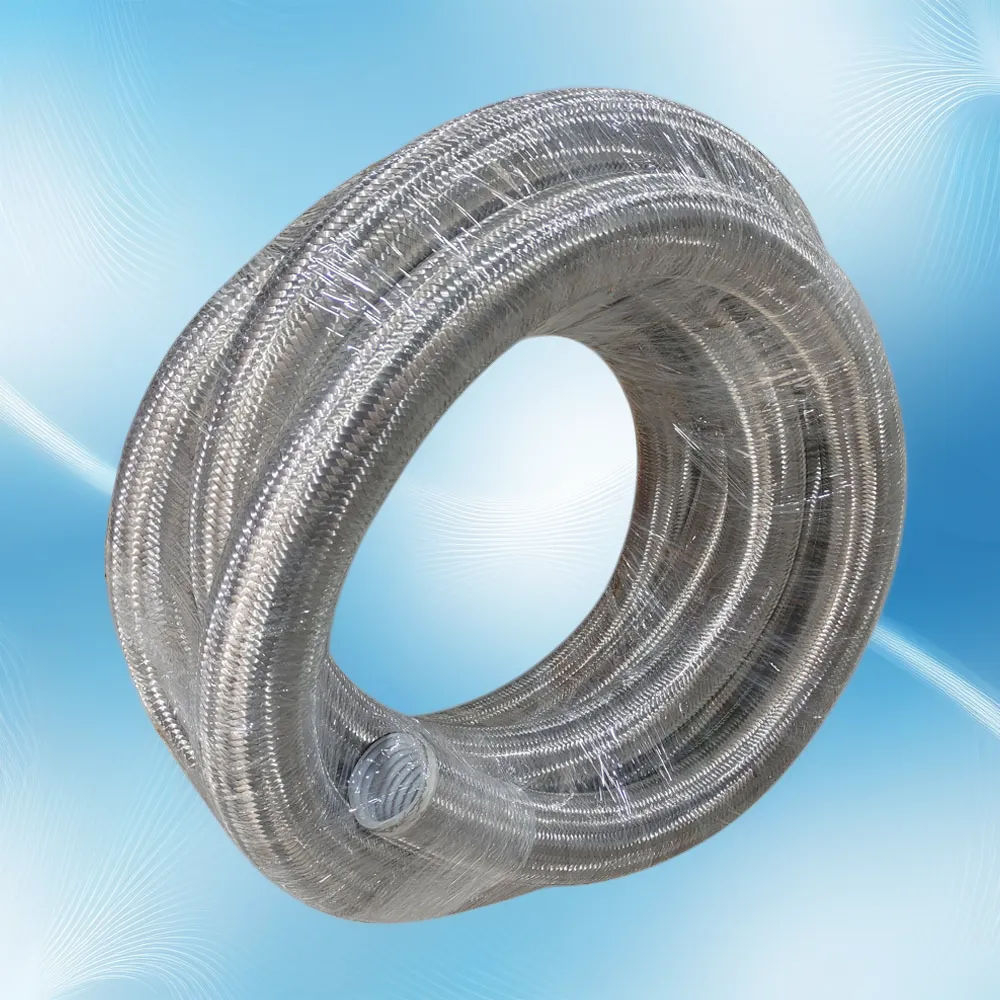

Welkom bij Teflon-X, the industry leader in advanced fluoropolymer hose solutions. Our Braided PTFE Hose with Stainless Steel Cover represents the gold standard for industrial safety and efficiency. Designed to withstand the most rigorous operational demands, this product integrates the chemical inertness of a PTFE core with the rugged structural integrity of a high-grade stainless steel exterior.

Whether you are operating a complex chemical processing plant, a precision semiconductor manufacturing facility, or a high-temperature oil system, our hoses ensure uninterrupted flow and safety. As a versatile flexibele teflonslang, it is specifically engineered to handle aggressive media that would degrade standard rubber or metal hoses, offering a long-lasting solution for critical infrastructure.

Superior Construction and Design

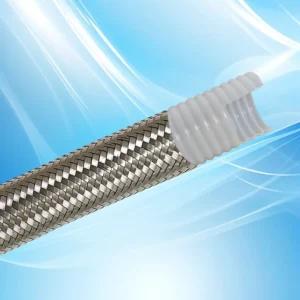

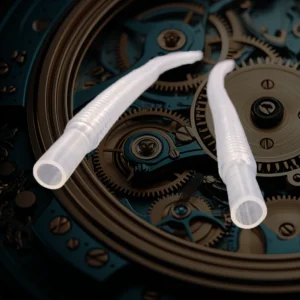

The secret to the performance of our roestvrijstalen gevlochten teflon slang lies in its dual-layer engineering. The inner liner consists of high-quality Polytetrafluoroethylene (PTFE). This material is renowned for its non-stick properties and nearly universal chemical resistance. Depending on your flexibility requirements, we offer both smooth bore and PTFE gegolfde slang designs. The corrugated (or convoluted) profile is essential for applications requiring significant maneuverability and kink resistance.

Surrounding this core is a robust exterior reinforcement. This gevlochten PTFE-slang features a single or double layer of braided stainless steel (typically Grade 304 or 316). This braiding not only protects the softer PTFE liner from external physical damage and abrasion but also significantly increases the pressure rating of the hose assembly. The result is a PTFE roestvrijstalen gevlochten slang that remains dimensionally stable even under high internal pressures.

Key Features and Operational Benefits

At Teflon X, we focus on solving real-world engineering challenges. Our teflon gevlochten slang offers distinct advantages:

- Extreme Temperature Resilience: Capable of operating in environments ranging from cryogenic lows of -200°C up to scorching highs of +260°C, making it ideal for thermal cycling applications.

- Ongeëvenaarde chemische weerstand: De PTFE-gevoerde flexibele slang is impervious to virtually all industrial chemicals, including strong acids, alkalis, and chlorinated solvents.

- Thermal Compensation: The unique design allows for thermal expansion and contraction, handling axial movements of up to ±30mm without compromising seal integrity.

- Static Dissipation: We offer conductive (carbon-lined) versions of the gevlochten ptfe-slang to prevent static charge build-up when transferring non-conductive fluids like fuels or solvents.

- Hygiene and Safety: Our hoses are FDA-compliant, ensuring they are safe for use in food, beverage, and pharmaceutical processing where purity is paramount.

Applications in Industry

De veelzijdigheid van kronkelige slangen and smooth bore PTFE assemblies allows them to be deployed across a vast sector of industries. In the semiconductor industry, where ultra-high purity is required, our hoses ensure no leachables contaminate the process. In chemical plants, the resistance to corrosive substances like sulfuric acid and aqua regia prevents dangerous leaks. Furthermore, the flexibility of our flexibele teflonslang makes it an excellent choice for correcting misalignment in piping systems or connecting vibrating machinery.

Technische specificaties

To ensure you select the correct PTFE roestvrijstalen gevlochten slang for your specific application, please review the standard parameters below. Teflon X can also customize lengths and fittings to meet your exact specifications.

| Product Parameter | Specificatiedetails |

|---|---|

| Product Name | Braided PTFE Hose with Stainless Steel Cover |

| Inner Core Material | Virgin PTFE or Black Conductive (Anti-static) PTFE |

| Outer Reinforcement | Stainless Steel Wire Braid (SS304 / SS316) |

| Structure Type | Available in Smooth Bore or Corrugated (Convoluted) |

| Temperatuurbereik | -200°C tot +260°C (-328°F tot +500°F) |

| Werkdruk | High Pressure Rated (Varies by diameter, up to 250 Bar) |

| Vacuum Resistance | Full vacuum rated models available (with internal spring support) |

| Axial Movement | Up to ±30mm (for specific expansion joint models) |

| Naleving | FDA 21 CFR 177.1550, ISO 9001 |

| Common Sizes | DN6 (1/4″) to DN150 (6″) |

Waarom Teflon X kiezen?

When you choose a roestvrijstalen gevlochten teflon slang from Teflon X, you are investing in reliability. Our rigorous quality control processes ensure that every PTFE gegolfde slang meets strict international standards before it leaves our facility. We understand that in high-stakes environments, failure is not an option.

Whether you need a vacuum-compatible solution or a specialized FDA-grade PTFE-gevoerde flexibele slang, our engineering team is equipped to provide technical support and custom fabrication services. We pride ourselves on rapid delivery and exceptional customer service.

Ready to Optimize Your Systems?

Contact us today to discuss your requirements, request a quote, or get technical advice on our Braided PTFE Hose producten.

Or email our sales specialist directly:

allison.ye@teflonx.com

Learn more about our company at Teflon X Website.

Beoordelingen

Er zijn nog geen beoordelingen.