Introduction to Premium PTFE Stainless Steel Braided Hose

Welkom bij Teflon-X, your premier destination for high-performance industrial fluid transfer solutions. Our flagship product, the PTFE Stainless Steel Braided Hose, represents the pinnacle of engineering for critical applications involving aggressive media, high temperatures, and high pressure. Whether you are managing complex chemical processing pipelines or demanding mining operations, our hoses provide the reliability and safety your infrastructure requires.

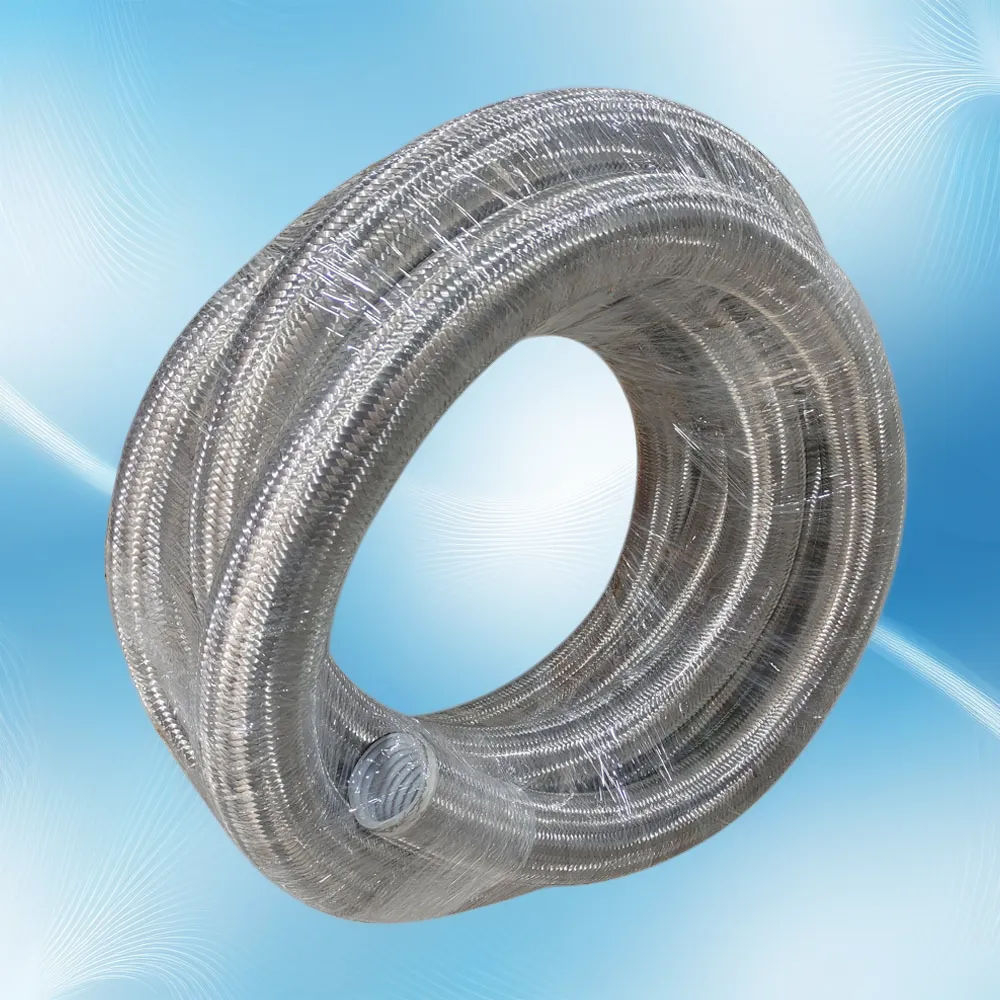

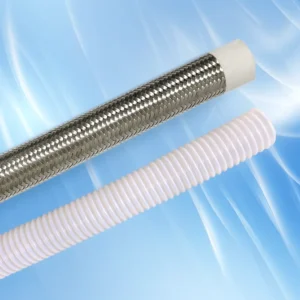

The core advantage of our gevlochten PTFE-slang lies in its unique construction. It combines a chemically inert PTFE (Polytetrafluoroethylene) liner with a robust, corrugated stainless steel outer shell. This dual-layer design ensures that the hose remains impervious to almost all industrial chemicals while maintaining structural integrity under stress. As a leading supplier, Teflon X is dedicated to providing a flexibele teflonslang that exceeds industry standards.

Why Choose Our Stainless Steel Braided Teflon Hose?

In the world of industrial hoses, versatility and durability are paramount. Our stainless steel braided Teflon hose is specifically designed to handle the toughest challenges. Unlike standard rubber or metal hoses, the PTFE lining offers a non-stick surface with an extremely low coefficient of friction. This means faster flow rates and zero residue buildup, which is crucial for maintaining purity in pharmaceutical and food processing applications.

Furthermore, the flexibility of our kronkelige slangen allows them to absorb significant axial and lateral displacements. This makes them the ideal solution for piping systems that experience vibration, thermal expansion, or misalignment. If your system requires a PTFE-gevoerde flexibele slang that can withstand continuous movement without fatigue, Teflon X has the solution.

Key Features and Applications

Ons PTFE gegolfde slang is engineered to resist some of the most corrosive substances known to man. It effectively handles concentrated sulfuric acid, chlorine gas, sodium hydroxide, and even aqua regia. This chemical resistance makes our teflon gevlochten slang an indispensable component in the chemical, petrochemical, and semiconductor industries.

- Extreme Chemical Resistance: The inert nature of the PTFE core ensures compatibility with virtually all chemicals.

- High-Temperature Performance: Operates efficiently in extreme temperature ranges, from cryogenic lows to scorching highs.

- Superieure flexibiliteit: The convoluted design of our flexibele teflonslang ensures easy installation in tight spaces.

- Abrasion Resistance: Specialized models are available for mining applications where external wear is a concern.

Technische specificaties

To help you select the right PTFE roestvrijstalen gevlochten slang for your specific needs, please refer to the general specifications below. For custom sizes or specific pressure ratings, please contact our engineering team.

| Parameter | Specificatiedetails |

|---|---|

| Inner Core Material | Virgin PTFE or Conductive (Anti-static) PTFE |

| Outer Reinforcement | Single or Double Stainless Steel Braid (SS304 / SS316) |

| Temperatuurbereik | -70°C to +260°C (-94°F to +500°F) |

| Drukclassificatie | Up to 250 Bar (depending on diameter and braid layers) |

| Standard Diameters | 1/4″ (DN6) to 4″ (DN100) |

| Fittings/Connections | Flanges, Camlocks, Threaded (NPT/BSP), Triclamp, JIC |

| Safety Factor | 4:1 (Burst Pressure to Working Pressure) |

Durability in Harsh Environments

For industries such as mining or flue gas desulfurization systems, standard hoses often fail due to abrasion or chemical attack. Our abrasion-resistant gevlochten PTFE-slang models feature added external protection layers to withstand physical wear and tear. The integration of a stainless steel braid not only provides pressure resistance but also acts as a shield against external mechanical damage.

When dealing with “aggressive media,” safety cannot be compromised. A leak in a line carrying chlorine gas or concentrated acid can be catastrophic. That is why every PTFE-gevoerde flexibele slang manufactured by Teflon X undergoes rigorous testing, including hydrostatic pressure tests and continuity checks, ensuring you receive a defect-free product.

Contact Teflon X for Your Custom Solutions

At Teflon X, we understand that every project is unique. Whether you need a standard kronkelige slang assembly or a custom-designed PTFE gegolfde slang with specific end fittings, our team is ready to assist you. We pride ourselves on fast turnaround times and exceptional customer support.

Don’t settle for inferior fluid transfer components. Upgrade to the reliability of a teflon gevlochten slang today.

Ready to order or need technical advice?

Click here to visit our Contact Page

Or email our sales specialist directly at:

allison.ye@teflonx.com

Explore more at Teflon X Official Website.

Beoordelingen

Er zijn nog geen beoordelingen.