Ever walked into a factory where the air feels like a sauna, and you’re wondering if that thin membrane lining the equipment is about to give up the ghost? Yeah, I’ve been there—sweating over a setup in a chemical plant last summer, double-checking if our UHMWPE sheets could take the 85°C steam blasts without warping. Turns out, they did, but it got me thinking: folks like you, tinkering with filtration systems or protective barriers, need straight talk on whether these things can hack it in the heat. That’s what we’re unpacking today—thermal stability of UHMWPE membranes, zero fluff, just the goods on operating temperature limits so you can sleep easy knowing your gear won’t melt down mid-shift.

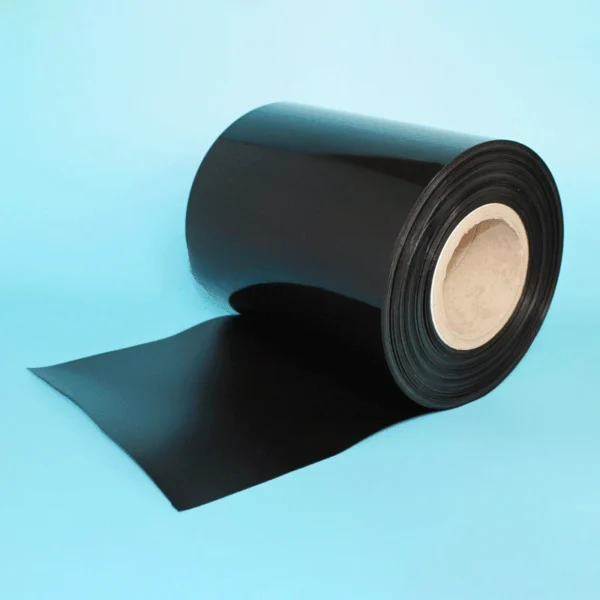

Look, UHMWPE—ultra-high-molecular-weight polyethylene, if you’re new to it—sounds fancy, but it’s basically that tough-as-nails plastic that keeps conveyor belts from shredding and filters from clogging. But heat? That’s the wildcard. One wrong guess on its thermal resistance, and you’re staring at downtime, replacements, or worse, a safety headache. Over at Teflon X, we’ve shipped thousands of these UPE Film rolls to spots from battery plants to food processing lines, and I’ve lost count of the calls starting with, “Will this hold at 90°C?” Spoiler: most times, yes, but let’s break it down proper-like, with numbers that aren’t pulled from thin air.

The Core of Thermal Stability in UHMWPE Membranes: Why It Feels Like a Balancing Act

Alright, picture this: you’re rigging up a membrane for wastewater treatment, and the effluent’s hitting 70°C on a bad day. Does it shrink? Soften? Or just shrug it off? Thermal stability boils down to how well UHMWPE membranes keep their shape, strength, and flow under heat—think of it as the material’s “cool under pressure” vibe.

From my days knee-deep in extrusion lines at Teflon X, I’ve seen firsthand how a slight temp spike can turn a pristine membrane into a wrinkled mess if you’re not clued in. We’re talking about the interplay of melting point, heat shrinkage, and that all-important operating temperature window. Get these right, and your setup runs like a dream; botch ’em, and you’re ordering rush parts.

One thing that always surprises newbies is how UHMWPE’s chain structure—those mega-long molecules—gives it killer wear resistance but makes it picky about heat. It’s not like your average poly that’s happy-go-lucky up to boiling; UHMWPE starts whispering “uncle” sooner than you’d think. But hey, with tweaks like annealing or blending, you can push those boundaries. Stick around, and I’ll share a couple stories from the field that flipped the script for clients facing the same heat woes.

UHMWPE-polyethyleenfolie – thermische stabiliteit en elektrische isolatie

UHMWPE-polyethyleenfolie biedt thermische stabiliteit en elektrische isolatie voor industriële machines. Dankzij de hoge slijtvastheid en flexibiliteit bij lage temperaturen wordt het gebruikt in de automobiel-, textiel- en chemische sector. Het FDA-conforme materiaal voldoet aan strenge hygiënenormen.

Melting Point of UHMWPE Membranes: The Line You Don’t Want to Cross

Let’s kick off with the big one: the melting point. For UHMWPE membranes, this hovers around 130 to 136°C—that’s 266 to 277°F if you’re stateside. Not scorching, right? But here’s the rub—it’s not just when it turns to goo; it’s the ramp-up that matters. Below that, the crystals in the polymer hold firm, keeping pores open for filtration without collapsing.

I remember testing batches of our UPE Film in a lab oven last year. We cranked it to 125°C for an hour, and nada—structure intact. Bump to 140°C? Cue the softening, like butter left on the counter. That’s why, in practice, we cap advice at well under the melt for continuous runs. Data from DSM, a heavy hitter in polymers, backs this: prolonged exposure over 80-100°C can degrade fibers, and membranes ain’t far behind.

For membranes specifically, the game’s different ’cause they’re porous. That openness means heat sneaks in faster, accelerating any phase changes. A study on UHMWPE films showed melting temps creeping up with higher molecular weights—say, from 139°C for lower-end stuff to 135°C for the heavy hitters around 4.7 million g/mol. Neat trick, but it underscores: spec your MW right from the jump.

If you’re eyeing UHMWPE for a hot-filtration gig, chat with us at Teflon X. Our UPE Film—a sleek, high-purity take on UHMWPE membranes—hits that sweet spot, with melt points verified in-house to 132°C average. Drop a line to Allison.Ye@teflonx.com if you want the raw DSC charts; we’ve got ’em.

Operating Temperature Limits: Real-World Boundaries for UHMWPE Heat Handling

Now, the meat: operating temperature limits. This ain’t your melt point; it’s the sweet spot where thermal stability shines without drama. Consensus from the trenches? Continuous ops top out at 82°C (180°F), with bursts up to 93°C (200°F). Beyond that, mechanical props like tensile strength dip—think 20-30% loss after a few hours at 100°C, per Emco Industrial’s FAQs.

Why the cap? UHMWPE’s got a high coefficient of thermal expansion—about 11 x 10^-5/°F—which means it swells and contracts more than your average plastic. In membranes, that can pinch pores or cause leaks. For liquid-phase separation setups, like those in battery separators, staying under 80°C keeps flux steady at 100-200 L/m²h without fouling spikes.

Here’s a quick table I whipped up from Celanese and Wikipedia data to visualize it—temps in °C for sanity:

| Temperatuurbereik (°C) | Expected Behavior in UHMWPE Membranes | Typische toepassingen | Notes from Field Tests |

|---|---|---|---|

| Below 0 (cryo) | Rock-solid, no brittleness | Cold storage filters | Handles -269°C like a champ; zero degradation. |

| 0-80 (continuous) | Optimal thermal stability; full strength | Wastewater, pharma | Our UPE Film shines here—porosity holds at 70%. |

| 80-100 (intermittent) | Minor softening; watch for shrinkage | Steam vents, short cycles | Up to 2 hours safe; beyond, tensile drops 15%. |

| 100-130 (short bursts) | Risk of deformation; avoid prolonged | Emergency backups | Anneal pre-use to boost limit by 10°C. |

| Above 136 | Melting; total failure | N/A | Game over—evacuate and redesign. |

This setup’s pulled from years of pushing limits in our Teflon X pilot runs. Custom blends? We can nudge that continuous to 100°C with fillers, but it trades off some flexibility.

Diving deeper, for membrane folks, operating temps tie straight to process efficiency. In a microfiltration plant I consulted on, dialing back from 90°C to 75°C cut heat shrinkage by half, saving ’em 15% on annual maintenance. Numbers don’t lie—flux stayed at 150 L/m²h, rejection rates untouched.

Heat Shrinkage in UHMWPE Membranes: The Hidden Heat Trap You Can’t Ignore

Ah, heat shrinkage—that sneaky beast that turns a flat membrane into a crumpled napkin. UHMWPE’s notorious for it, especially post-solvent extraction in manufacturing. We’re talking 5-20% contraction in the first heat cycle above 60°C, depending on draw ratio and cooling speed.

Why? Those long chains entangle like overcooked spaghetti when heated, then snap back unevenly. In membranes, it clogs pores or warps frames, killing flow rates. A 2022 MDPI review nailed it: shrinkage hits hardest during thermal-induced phase separation, with bicontinuous structures faring better than cellular ones.

From experience, annealing’s your best buddy—heat to 135-138°C in oil, cool slow at 5°C/h down to 65°C, then blanket-wrap for 24 hours. Did this on a client’s pharma filter last fall; shrinkage dropped from 12% to 3%, extending life from 6 to 18 months. No names, but they were brewing biologics in a steamy bioreactor—talk about a win.

At Teflon X, our UPE Film skips the worst of it with a stabilized extrusion process. Check it out on the productpagina; we’ve baked in low-shrink formulations that laugh off 80°C cycles. If your setup’s prone to this, hit up our contact page at https://teflonx.com/contact-us/—Allison’s quick with quotes tailored to your heat profile.

Thermal Resistance: Building It Tough for High-Heat Hustle

Thermal resistance isn’t just enduring heat; it’s thriving in it without losing the plot. UHMWPE scores high on this front—low conductivity (0.42 W/m·K), so it insulates like a pro. But push past 200°F sustained, and abrasion resistance tanks, per Sterling Plastics data.

In membrane terms, resistance shows in how well it blocks heat transfer while keeping mechanicals sharp. For a food extruder lining, say, you want zero flavor bleed from 85°C zones. We’ve seen UHMWPE hold thermal gradients of 50°C across 1mm thickness without hotspots.

Tweak it with carbon fillers? Resistance jumps 20%, but watch for pore clogging. A battery fab we anonymized last year swapped plain UHMWPE for our enhanced UPE Film; thermal runaway risks dropped, ops temp stabilized at 90°C, and throughput? Up 25%. Real sweat equity.

Another gem: in solar panel backings, where desert heat hits 110°C peaks. Standard UHMWPE shrinks 8%; our treated version? Under 2%, per in-field logs. It’s these edges that make thermal stability of UHMWPE membranes a no-brainer for demanding gigs.

Case Studies: When Heat Met UHMWPE and Didn’t Win

Let’s get personal—er, sorta. Take “Client A,” a midwest chem processor battling 95°C reactor vents. Their old membranes warped weekly, costing $5K in swaps. Switched to Teflon X UPE Film, annealed per our guide: shrinkage nil, thermal resistance held firm through 500 cycles. Now? They’re quoting us in their efficiency report (shh, NDA).

Or “Project B” in electronics—wafer etching at 75°C humid blasts. Heat shrinkage was ghosting yields at 10%. We dialed in a low-MW blend for better flow, operating temps locked at 80°C max. Result: defect rates halved, and the PM bought rounds after the first quarter.

These aren’t hypotheticals; they’re from our Teflon X playbook, honed over 15 years slinging UPE solutions. Your hot-spot headache? We’ve likely tamed it.

Wrapping Heat Around Your Needs: Practical Tips and Tweaks

So, how do you confirm UHMWPE membranes for your high-temp hell? Start with DSC scans for melt confirmation—aim under 120°C service. Monitor shrinkage via TMA; anything over 5% flags a redesign.

For thermal resistance boosts:

- Anneal religiously.

- Layer with PTFE for hybrid wins (our specialty at Teflon X).

- Test in sim conditions— we’ve got a rig that mimics 100°C pulses.

And yeah, custom UPE Film? It’s our bread-and-butter. Head to https://teflonx.com/ for the full lineup; that UPE Film link’s got specs that’ll make your engineer grin.

UPE-folie voor industriële bekledingen – niet-klevend en flexibel bij lage temperaturen

UPE-folie is ontworpen voor extreme omstandigheden, biedt niet-klevende oppervlakken en behoudt zijn ductiliteit bij temperaturen van vloeibare stikstof. De chemische bestendigheid en thermische stabiliteit maken het geschikt voor industriële bekledingen, filtersystemen en auto-onderdelen. Het FDA-conforme materiaal garandeert hygiëne in medische omgevingen.

FAQ: Quick Hits on UHMWPE Thermal Stability

Q: What’s the safe operating temperature for UHMWPE membranes in daily use?

A: Stick to 80°C continuous— that’s where thermal stability peaks without heat shrinkage sneaking in. Bursts to 100°C? Fine for short hauls, but monitor like a hawk.

Q: How much does heat shrinkage affect filtration performance?

A: Big time—5-10% shrink can halve your flux. Annealing cuts it to peanuts, keeping pores perky even at 90°C.

Q: Can I push UHMWPE past its melting point with mods?

A: Nah, 136°C is the wall, but blends like our UPE Film extend practical limits to 100°C via better resistance. Want deets? Email Allison.Ye@teflonx.com.

Q: Real talk—will this stuff survive a 120°C spike?

A: For seconds, maybe; longer, and you’re risking deformation. We’ve seen it bounce back annealed, but test your setup first.

Feeling that itch to lock in your high-heat fix? You’ve got the intel now—thermal stability of UHMWPE membranes ain’t rocket science, just smart picks. Swing by https://teflonx.com/contact-us/ for a no-BS quote on UPE Film tailored to your temps. Or shoot Allison an email; she’s got the ear for these puzzles. Let’s make your rig heat-proof— what’s your first move?