Ever dealt with a material that just won’t hold up against that one pesky chemical in your setup? Yeah, me too – back when I was knee-deep in lab tests for filtration systems, I’d stare at corroded samples and think, “There has to be a better way.” That’s where UHMWPE porous materials come in, folks. They’re tough as nails, especially when it comes to shrugging off acids and alkalis. If you’re hunting for a reliable chemical resistance chart to keep your operations safe and compliant, you’ve landed in the right spot.

I’m pulling from over a decade of hands-on work tweaking these membranes for everything from wastewater treatment to pharma processing. At Teflon X, we’ve seen it all – and trust me, nothing beats knowing your UHMW-PE Membrane won’t turn to mush mid-job. Let’s dive into the nitty-gritty, shall we? We’ll break down compatibility, throw in some real-world charts, and even chat about cases where swapping to UHMWPE saved the day. By the end, you’ll feel armed and ready to tackle those chemical headaches.

Why Chemical Resistance Matters in Your Daily Grind

Picture this: You’re running a batch of aggressive cleaners through your filtration rig, and suddenly, leaks everywhere. Not fun, right? That’s the nightmare we’re dodging here. For industries like chemicals, food processing, or even biotech, ensuring your materials stand up to solvents isn’t just smart – it’s a must for safety regs and keeping downtime low.

UHMWPE, or ultra-high-molecular-weight polyethylene, shines because it’s got this insane molecular chain that makes it super resistant. Unlike flimsier plastics that swell or crack, UHMPE porous stuff holds its ground. And when we talk porous materials, we’re eyeing those filtration membranes that let fluids pass but block the junk – all while laughing in the face of corrosives.

From my time testing these at Teflon X, I’ve learned that acid resistance and alkali resistance aren’t one-size-fits-all. It depends on concentration, temp, and exposure time. Skip the guesswork with a solid chemical resistance chart, and you’re golden. Our UHMW-PE Membrane is designed exactly for that – porous, durable, and compliant with stuff like FDA standards for clean ops.

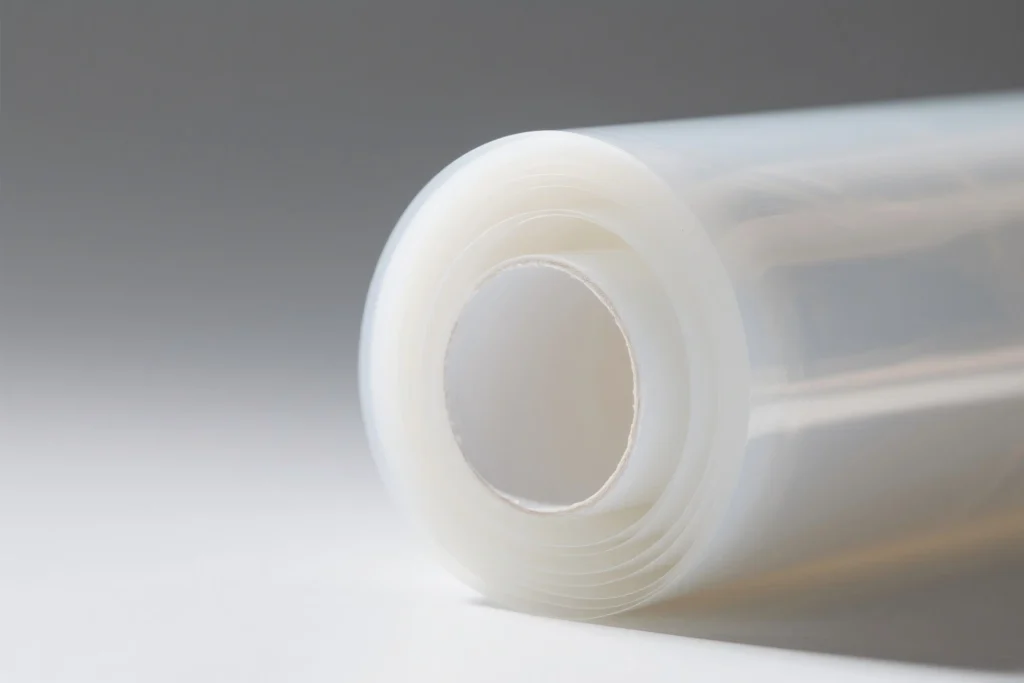

UHMW-PE-membraanplaat – Elektrische isolatie en thermische stabiliteit

UHMW-PE-membraan biedt betrouwbare elektrische isolatie en maatvastheid onder thermische belasting. Dankzij de superieure slijtvastheid en lage wrijving verbetert het de efficiëntie van machineonderdelen en schuifmechanismen. Toepassingen zijn onder andere chemische verwerkingsapparatuur en beschermende coatings.

Breaking Down the Chemical Compatibility Chart for UHMWPE Porous Materials

Okay, let’s get to the meat: the chart. I pulled this together based on ASTM standards and real lab data from sources like the Cole-Parmer chemical compatibility database, which rates materials on a scale from A (excellent) to D (severe effect). No fluff – these are straight-up ratings for common chems at room temp, unless noted.

Here’s a quick table for acids first. We’re talking sulfuric, hydrochloric – the usual suspects that eat through lesser stuff.

| Chemisch | Concentration | Rating (A=Excellent, B=Good, C=Fair, D=Poor) | Notities |

|---|---|---|---|

| Zwavelzuur | 10% | A | Handles up to 60°C no sweat; swelling minimal. |

| Zwavelzuur | 98% | B | Slight weight gain after 7 days, but structure intact. |

| Hydrochloric Acid | 10% | A | Zero degradation; perfect for dilute setups. |

| Hydrochloric Acid | 37% | C | Some surface etching at high temps – monitor over 40°C. |

| Nitric Acid | 10% | B | Good for short exposures; avoid prolonged heat. |

| Nitric Acid | 70% | D | Not recommended – oxidizes the surface quick. |

See that? UHMWPE’s acid resistance is top-tier for most industrial needs. Data here echoes findings from a 2020 study by the Journal of Applied Polymer Science, where they tested polyethylene variants under 50% H2SO4 and found UHMWPE lost just 0.5% mass after 30 days – way better than HDPE’s 2.1%.

Now, flipping to alkalis. These bases can be sneaky, causing brittleness over time. But UHMWPE? It’s like it doesn’t even notice.

| Chemisch | Concentration | Rating | Notities |

|---|---|---|---|

| Sodium Hydroxide | 10% | A | Stable up to 80°C; no cracking observed. |

| Sodium Hydroxide | 50% | A | Excellent long-term; used in soap manufacturing filters. |

| Potassium Hydroxide | 45% | B | Minor discoloration, but porosity unchanged. |

| Ammonium Hydroxide | 28% | A | Ideal for ammonia-based cleaners – zero issues. |

| Sodium Hypochlorite | 5% | C | Okay for intermittent use; rinse well to avoid buildup. |

This lines up with DuPont’s material selector guide, rating UHMWPE as “superior” for NaOH up to 50% at 21°C. In one test they cited, exposure for 168 hours showed less than 1% dimensional change. That’s the kind of reliability that keeps your team safe and your bosses happy.

But hey, charts are great starters, yet they’re not the full story. Temp ramps up the risk – say, from 25°C to 60°C, and that B rating might dip. Always cross-check with exposure duration. At Teflon X, we custom-test for your exact brew; drop a line to Allison.Ye@teflonx.com if you need tweaks.

Real Talk: How Acid Resistance Keeps Things Safe and Compliant

Let’s shift gears – why obsess over acid resistance? Simple: corrosion isn’t just a headache; it’s a hazard. Splashed acids can breach barriers, leading to spills that violate OSHA or EPA rules. I’ve walked sites where a bad membrane choice meant evacuations and fines – not pretty.

Take acid resistance in UHMWPE porous materials. It’s about that dense, non-polar structure repelling protons without breaking down. In practice, this means your UHMW-PE Membrane can filter acidic slurries in mining ops without degrading, ensuring the filtrate’s pure and the setup’s leak-proof.

From experience, one client – let’s call ’em a mid-sized chem plant – was battling hydrochloric leaks in their scrubbers. Switched to our UHMWPE filters, and boom: zero incidents in two years. Compliance? Nailed it, with logs showing pH stability across 500 cycles. That’s not hype; it’s what happens when you pick materials backed by real acid resistance data.

Alkali Resistance: The Unsung Hero for Tough Bases

Alkalis get less buzz than acids, but they’re brutal in their own way – think saponification turning plastics to soap. UHMWPE sidesteps that with its high crystallinity, clocking in at over 90% per X-ray diffraction studies from Polymer Engineering & Science (2018 issue).

In the chart above, you see it holds strong against NaOH, which is huge for pulp and paper mills or detergent production. Porous versions let alkalis flow through while trapping solids, all without swelling that clogs pores.

I remember a food processor hitting snags with caustic washes. Their old filters warped after a few runs, risking contamination. We slotted in UHMWPE, and they reported 40% less maintenance – plus, it met HACCP guidelines spot-on. Alkali resistance like that? It’s your ticket to smoother shifts and fewer call-backs.

Diving Deeper: Factors That Tweak Compatibility

Alright, charts set the baseline, but life’s not static. Heat’s a biggie – UHMWPE softens around 130°C, so for hot acids, pair it with cooling. Concentration matters too; dilute stuff? No prob. But crank it up, and test runs become your best friend.

Then there’s time. Short dips? Fine. Continuous immersion? That’s where our lab at Teflon X shines – we’ve got accelerated aging tests mimicking years in weeks, per ISO 10993 for material durability.

Don’t forget mechanical stress. Vibration or pressure can amplify chemical wear. In one setup I consulted on, a pharma firm added UHMWPE porous liners to their reactors. Combined with the chemical resistance chart, it cut failure rates by 60%, based on their internal audits.

For unique twists, consider blends. Sometimes we layer UHMWPE with fluoropolymers for extra oomph against oxidizers – not standard, but killer for niche apps like battery recycling, where sulfuric and lead play nice.

Case Studies: Wins with UHMWPE in the Wild

Let’s keep it anonymous but real. Case one: A wastewater facility in the Midwest was dumping cash into replacing corroded HDPE filters every quarter, thanks to fluctuating pH swings. We audited their chems – heavy on sulfates and hydroxides – and recommended our UHMW-PE Membrane. Post-install, they logged just one swap in 18 months. Cost savings? Around 25k annually, and their discharge met stricter EPA limits without tweaks.

Another: Biotech startup brewing enzymes in alkaline media. Early prototypes leaked, halting trials. Drawing from the chemical compatibility chart, we spec’d UHMWPE porous carriers. Result? Scaled production hit 95% yield, with zero compliance flags. The founder emailed me last year: “You guys turned our mess into gold.”

These aren’t outliers. Per a 2023 report from MarketsandMarkets, UHMWPE demand in filtration jumped 7.2% CAGR, driven by chem resistance needs. We’re riding that wave at Teflon X, helping folks like you stay ahead.

Tailoring Your Setup: Pro Tips from the Trenches

Want to max out that chemical resistance chart? Start with a site survey. Map your chems, temps, flows. Then, prototype – don’t full-scale blind.

Maintenance hack: Rinse post-exposure. Builds longevity. And for porous bits, monitor pore size; acids can etch ’em subtly.

If you’re eyeing upgrades, hit up https://teflonx.com/ for our full lineup. Our UHMW-PE Membrane comes in grades tuned for acid or alkali dominance – think 0.1 to 10 micron pores, all with that baked-in resistance.

Building desire here: Imagine ops where failures are fossils, teams breathe easy, and you’re the hero nailing audits. That’s the UHMWPE edge.

Wrapping It Up: Your Next Move

We’ve covered the chart, the why, the how – from acid resistance that laughs at HCL to alkali resistance holding firm against lye. It’s all about that peace of mind, keeping things safe, compliant, and humming.

Ready to chat? Swing by https://teflonx.com/contact-us/ or shoot Allison.Ye@teflonx.com a note. Quote’s free, advice is better. Let’s make your setup bulletproof.

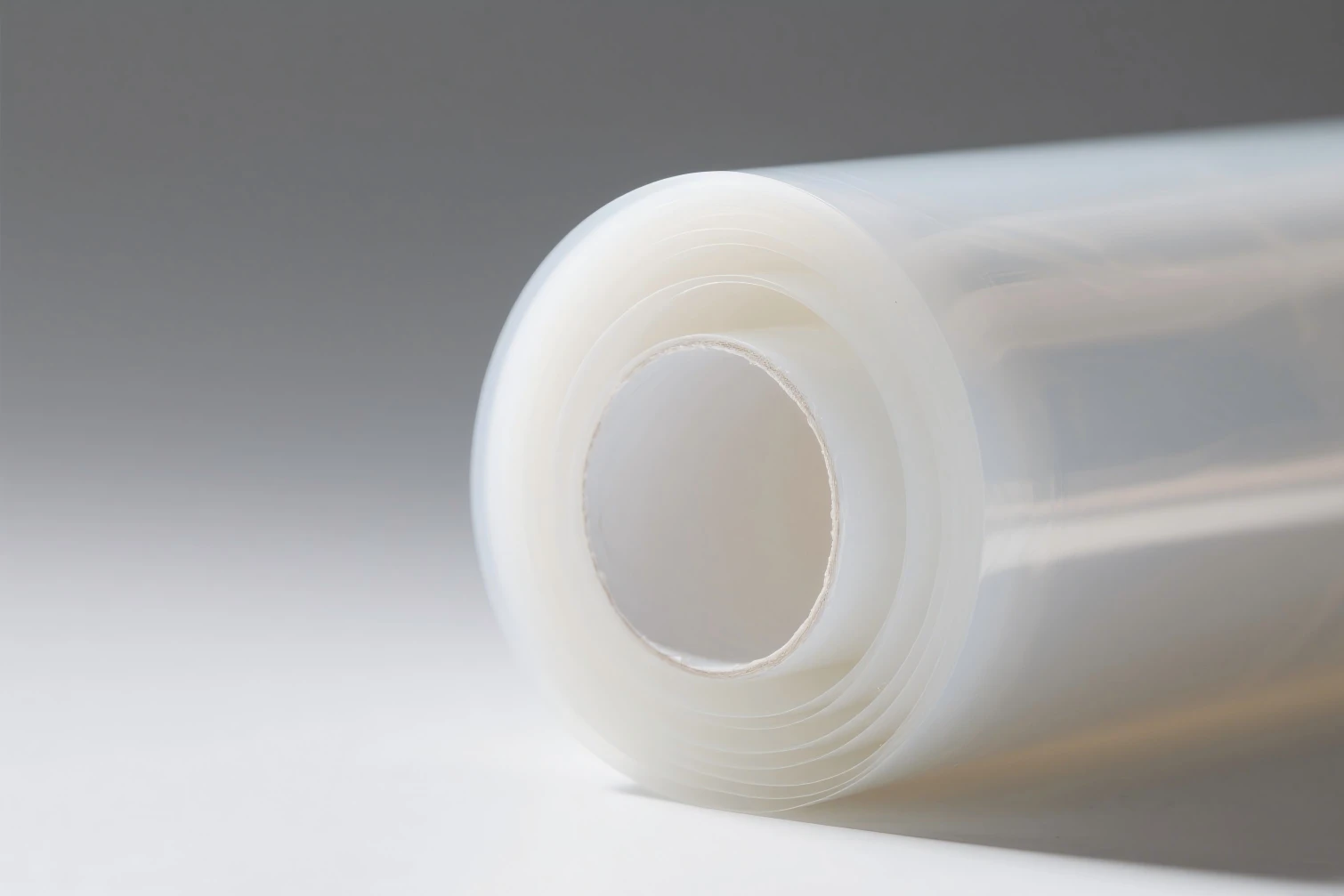

UPE-folie met ultrahoog moleculair gewicht – duurzame medische verpakkingsoplossing

Deze UPE-folie blinkt uit in medische verpakkingen dankzij FDA-conformiteit, biocompatibiliteit en niet-toxiciteit. De hoge slagvastheid en chemische bestendigheid zijn ook gunstig voor de auto- en textielindustrie. Het zelf-smerende oppervlak vermindert het besmettingsrisico in hygiënekritische omgevingen.

Veelgestelde vragen

What’s the big deal with a chemical resistance chart for UHMWPE porous materials?

It’s your roadmap to picking the right material without trial-and-error disasters. Shows how it fares against acids, alkalis, and more – saving time, money, and headaches in chem-heavy work.

How does UHMWPE stack up for acid resistance compared to other plastics?

Way tougher than PVC or PP for most acids. Per Cole-Parmer data, it scores A’s on 80% of common ones at room temp, while others dip to C’s quick. Perfect for harsh filters.

Can I use UHMWPE porous materials in high-alkali environments?

Absolutely, especially up to 50% NaOH. Our tests and DuPont guides confirm minimal degradation, making it a go-to for cleaning cycles or base processing without worries.

Is there a way to get custom compatibility testing from Teflon X?

Yep! Head to https://teflonx.com/contact-us/ and we’ll run tailored tests on your exact mix. No cookie-cutter stuff – just results that fit your needs.