Przegląd produktu

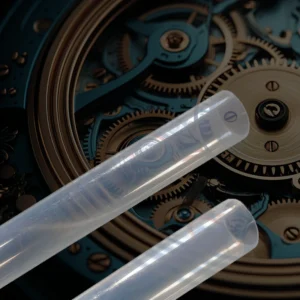

Experience unmatched protection with Teflon X’s heat shrink tubing, featuring high clarity PFA construction for superior optical transparency and industrial-grade performance. Our heat shrink tubing is meticulously designed for low friction and exceptional chemical resistance, safeguarding wires and connections in the most demanding environments. The non-stick properties of this heat shrink tubing effectively prevent debris adhesion, making it an essential solution for food processing, medical equipment, and beyond. With UL certification ensuring safety and reliability, Teflon X’s heat shrink tubing delivers robust insulation while maintaining crystal-clear visibility for effortless inspections and maintenance.

As a leader in fluoropolymer innovations, Teflon X provides premium heat shrink tubing that excels in harsh conditions, from extreme temperatures to corrosive exposures. Discover our complete lineup at https://teflonx.com/, or connect with our team through the Strona kontaktowa or via email at Allison.Ye@teflonx.com for tailored recommendations on heat shrink tubing Aplikacje.

Główne cechy

- Exceptional High Clarity: Provides unparalleled optical transparency in heat shrink tubing for precise visual monitoring of wiring and components.

- Low Friction Design: Ensures smooth installation and reduced wear, a core advantage of our advanced heat shrink tubing.

- Superior Chemical Resistance: Shields against acids, solvents, and corrosives, prolonging the life of protected wires with reliable heat shrink tubing.

- Powierzchnia nieprzywierająca: Prevents buildup of contaminants and simplifies cleaning, ideal for hygienic environments using heat shrink tubing.

- Broad Temperature Range: Operates from -200°C to +260°C continuously, with short-term peaks up to 300°C for versatile heat shrink tubing use.

- UL-Certified Safety: Meets stringent standards for flammability and electrical performance in heat shrink tubing for industrial wiring.

- Excellent Electrical Insulation: High dielectric strength protects against shorts and enhances safety in heat shrink tubing Aplikacje.

- UV and Abrasion Resistance: Maintains integrity in outdoor and high-wear settings, supporting durable heat shrink tubing installations.

- Flexible Shrink Ratio: 2:1 ratio allows secure conformity to irregular shapes with our heat shrink tubing.

Dane techniczne

Teflonowe X-y heat shrink tubing adheres to industry-leading standards for quality and performance. Below is a comprehensive table of key parameters:

| Parametr | Specification | Notatki |

|---|---|---|

| Tworzywo | Perfluoroalkoxy (PFA) | Fluoropolymer for superior performance |

| Kolor | Clear/Transparent | High optical clarity for visual inspection |

| Shrink Ratio | 2:1 | Expands to fit over components, shrinks to 50% of original diameter |

| Operating Temperature | -200°C to +260°C (continuous) | Short-term up to +300°C; suitable for cryogenic to high-heat uses |

| Shrink Temperature | 150°C – 200°C | Quick recovery with standard heat sources like hot air guns |

| Wytrzymałość dielektryczna | >15 kV/mm | Excellent insulation for high-voltage applications |

| Wytrzymałość na rozciąganie | ≥25 MPa | High mechanical durability |

| Elongation at Break | ≥300% | Flexible and resistant to cracking |

| Hardness (Shore D) | 55 – 65 | Balances flexibility with rigidity |

| Specific Gravity | 2.15 g/cm³ | Lightweight yet robust |

| Flammability | UL 224 VW-1 | Self-extinguishing, low smoke generation |

| Standard Sizes (ID) | 1.0 mm – 50 mm | Custom sizes available upon request |

| Wall Thickness (Recovered) | 0.2 mm – 2.0 mm | Thin walls for space-constrained designs |

Note: Specifications are based on standard testing methods (e.g., ASTM D2671). For exact values tailored to your application, contact Teflon X.

Aplikacje

Teflonowe X-y heat shrink tubing is engineered for versatility across critical sectors:

- Industrial Wiring and Electronics: Insulates harnesses and connectors with high-clarity heat shrink tubing for reliable, inspectable protection.

- Food Processing and Medical Equipment: Non-stick, low-friction heat shrink tubing prevents contamination in sterile and hygienic operations.

- Aerospace and Automotive: Withstands extreme temperatures and chemicals using durable heat shrink tubing for engine and avionics wiring.

- Chemical and HVAC Systems: Corrosion-resistant heat shrink tubing shields against harsh fluids and environmental stresses.

- Semiconductor and Laboratory: High-purity heat shrink tubing supports contamination-free assembly and fluid handling.

Compliant with UL, RoHS, and SEMI standards, our heat shrink tubing integrates seamlessly into regulated workflows.

Why Choose Teflon X’s Heat Shrink Tubing?

Teflon X stands out with heat shrink tubing that combines high clarity, low friction, and unmatched durability, backed by decades of fluoropolymer expertise. Our UL-certified products undergo rigorous ISO-compliant testing to guarantee performance in the toughest conditions. Elevate your industrial wiring solutions—reach out today at Allison.Ye@teflonx.com Lub https://teflonx.com/contact-us/ for quotes, samples, or custom heat shrink tubing options.

Opinie

Na razie nie ma opinii o produkcie.