Przegląd produktu

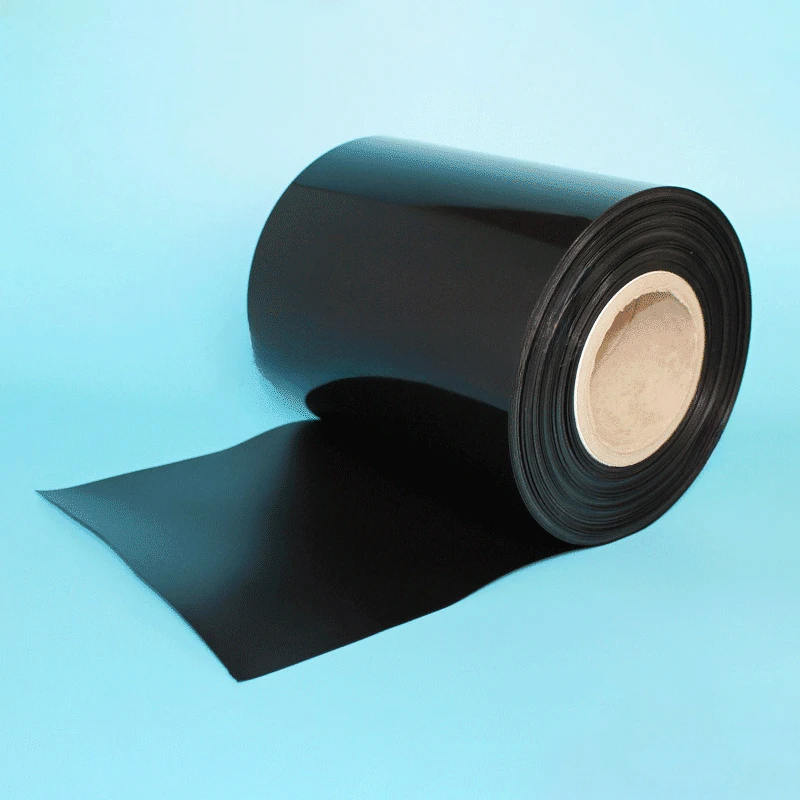

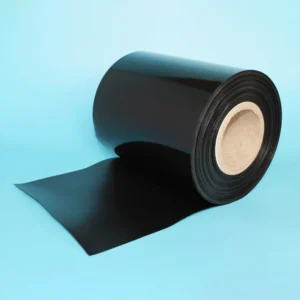

Revolutionize medical packaging and beyond with Teflon X’s UPE Film, an ultra-high molecular weight polyethylene (UHMWPE) material engineered for uncompromising safety and performance. This premium UPE Film shines in medical applications, offering full FDA compliance under 21 CFR 177.1520, exceptional biocompatibility, and complete non-toxicity to ensure hygienic, contamination-free environments. With high impact strength that absorbs shocks without failure and robust chemical resistance against acids, alkalis, and solvents, our UPE Film safeguards sensitive contents while reducing risks in hygiene-critical settings.

The self-lubricating surface of this UPE Film minimizes friction and adhesion, preventing microbial buildup and easing sterilization processes—ideal for sterile packaging and implants. Extending its versatility, Teflon X’s UPE Film supports automotive components for durable seals and textile industries for protective linings, all while maintaining low-temperature flexibility down to -200°C. Molecular weight exceeding 3,000,000 g/mol delivers inherent toughness and wear resistance up to 15 times that of carbon steel. Elevate your solutions with our reliable UPE Film—learn more at teflonx.com.

Główne cechy i korzyści

Teflonowe X-y UPE Film leverages advanced UHMWPE formulation to provide these vital properties, tailored for medical and industrial excellence:

- FDA Compliance and Biocompatibility: Meets stringent 21 CFR 177.1520 standards for food and medical contact, non-toxic, odorless, and hypoallergenic for safe use in implants, packaging, and devices.

- Wysoka wytrzymałość na uderzenia: Unrivaled toughness among thermoplastics, with no-break Izod impact to protect against drops and handling stresses in medical transport.

- Odporność chemiczna: Inert to corrosive substances, moisture, and disinfectants, ensuring stability and longevity in sterilized environments without degradation.

- Self-Lubricating Surface: Ultra-low friction (0.05–0.15 coefficient) reduces contamination risks by preventing sticking and bacterial adhesion in hygiene-sensitive applications.

- Non-Adhesive Properties: Low surface energy repels residues and facilitates easy cleaning, enhancing sterility in medical packaging and processing lines.

- Thermal and Low-Temperature Stability: Flexible from -200°C to +80°C, retaining ductility for cryogenic medical storage without brittleness or warping.

- Wear and Abrasion Resistance: 15× superior to carbon steel, extending shelf life in protective barriers for automotive and textile uses.

- Lightweight Versatility: Low density (0.93 g/cm³) for efficient packaging, available in thin films or sheets for custom medical solutions like drug delivery systems.

As a durable UPE Film, it combines safety, resilience, and efficiency, outperforming standard polymers in biocompatibility and contamination control for healthcare innovation.

Aplikacje

Teflonowe X-y UPE Film is the trusted choice for high-stakes environments, where biocompatibility and durability drive performance across sectors:

- Medical Packaging: Sterile barriers, blister packs, and implant wrappers, leveraging FDA compliance and non-toxicity to maintain product integrity and reduce contamination.

- Biomedical Devices: Coatings for orthopedic implants, catheters, and prosthetics, benefiting from high impact strength and self-lubrication for smooth, safe functionality.

- Automotive Components: Protective films for seals, gaskets, and interior linings, providing chemical resistance and low friction to withstand harsh conditions.

- Textile Industries: Anti-abrasion linings for machinery and protective fabrics, ensuring durability in high-wear processing without material transfer.

- Food and Hygiene Processing: Compliant liners for equipment and packaging, minimizing bacterial risks with non-adhesive, easy-to-clean surfaces.

- Pharmaceutical Delivery: Flexible films for drug pouches and transdermal patches, offering thermal stability for cold-chain logistics.

From safeguarding medical supplies to enhancing industrial resilience, our UPE Film delivers proven, contamination-resistant performance.

Dane techniczne

Poniżej znajduje się kompleksowa tabela standardowych parametrów dla Teflonu X Ultra-High Molecular Weight UPE Film. Customized variants, such as enhanced biocompatibility grades, are available—contact us for tailored UPE Film specyfikacje.

| Nieruchomość | Wartość/zakres | Standard testu/uwagi |

|---|---|---|

| Rodzaj materiału | Polietylen o ultrawysokiej masie cząsteczkowej (UHMWPE) | ASTM D4020 |

| Masa cząsteczkowa | >3 000 000 g/mol | Chromatografia żelowo-permeacyjna |

| Gęstość | 0,93 g/cm³ | ASTM D792 |

| Wytrzymałość na rozciąganie | 19,3-23 MPa | ASTM D638 |

| Wydłużenie przy zerwaniu | >300% | ASTM D638 |

| Twardość Shore D | 60-65 | ASTM D2240 |

| Wytrzymałość na uderzenia (Izod) | Bez przerwy (Niewzmocniony) | Najwyższa wśród tworzyw termoplastycznych |

| Współczynnik tarcia | 0,05-0,15 (dynamiczny) | Porównywalny do PTFE |

| Odporność na zużycie | 15x Stal węglowa | Test ścieralności Taber |

| Temperatura pracy | -200°C do +80°C | Ciągłe użytkowanie |

| Odporność chemiczna | Doskonały (kwasy, zasady, rozpuszczalniki) | Z wyjątkiem kwasów utleniających |

| Absorpcja wody | <0,01% (24 godz.) | ASTM D570 |

| Grubość | 0,1-5 mm | Możliwość dostosowania |

| Szerokość | Do 2 m | Format rolki lub arkusza |

| Zgodność z FDA | Tak (nietoksyczny, bezpieczny w kontakcie z żywnością) | 21 CFR 177.1520 |

| Porowatość (mikroporowata) | 30-70% (opcja) | Dla klas filtracji |

| Wytrzymałość dielektryczna | 20-30 kV/mm | ASTM D149 (wartość szacunkowa dla arkuszy) |

Uwaga: Wartości są typowe i mogą się różnić w zależności od procesu przetwarzania i gatunku. Szczegółowe arkusze danych można znaleźć na stronie teflonx.com.

Dlaczego warto wybrać Teflon X?

Teflon X excels in delivering cutting-edge polymer solutions, with our UPE Film undergoing rigorous FDA-aligned testing for biocompatibility and safety. This durable UPE Film integrates seamlessly into medical packaging and industrial applications, slashing contamination risks and boosting efficiency. Our commitment to innovation, global supply, and expert support positions us as your premier partner for high-performance UPE Film.

Protect your critical assets with Teflon X’s advanced UPE Film-Zapoznaj się z naszą ofertą na stronie teflonx.com or connect through our Strona kontaktowa. For expert advice, email teflonx.com.

Opinie

Na razie nie ma opinii o produkcie.