High-Temperature Teflon Tube | PTFE Insulation Sleeve for Electronics

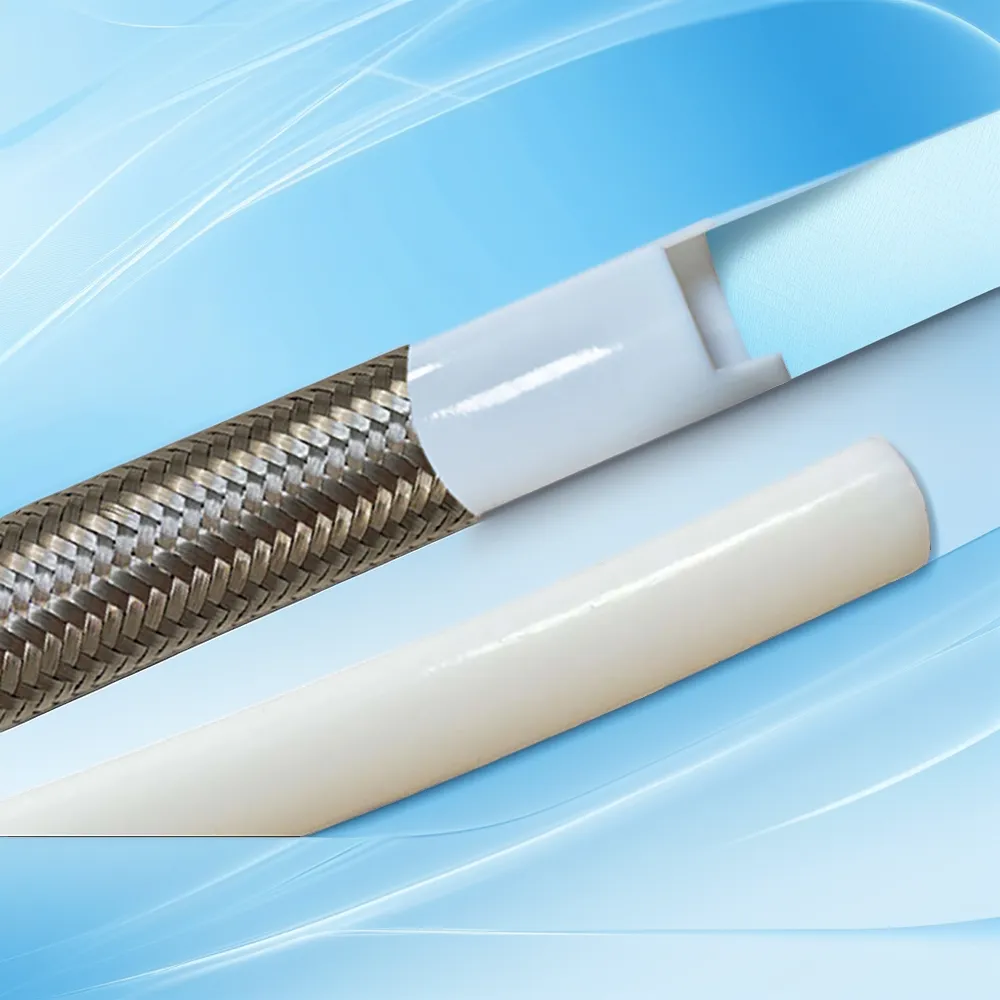

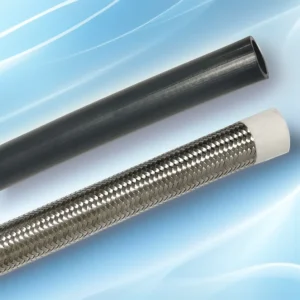

Welcome to Teflon X, your industry-leading ptfe tube manufacturer specializing in high-performance insulation solutions. In the rapidly evolving sectors of global electronics manufacturing, aerospace engineering, and semiconductor production, the protection of sensitive components is paramount. Our High-Temperature Teflon Tube serves as the ultimate barrier, offering superior dielectric properties combined with the rugged mechanical protection of a stainless steel braided teflon hose.

While standard plastic tubing often melts or degrades under electrical load or thermal stress, our premium polytetrafluoroethylene tubing thrives in these environments. It is the preferred choice for insulating high-voltage cables, protecting wiring harnesses in aircraft, and shielding delicate semiconductor components from environmental hazards.

Superior Dielectric Properties for Electronics

The primary advantage of using a ptfe tube in electronic applications is its exceptional electrical insulation capability. PTFE has a low dielectric constant and a high dielectric strength, meaning it effectively prevents electrical arcing and signal interference. This makes our ptfe teflon tubing an essential component for coaxial cables, high-frequency signal lines, and high-voltage interconnects.

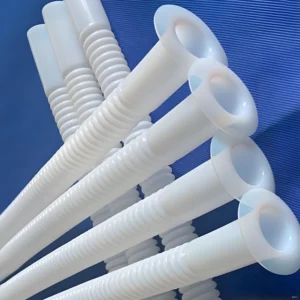

Unlike lower-grade insulators, our flexible ptfe tubing maintains these electrical properties over a wide range of frequencies and temperatures. Whether used as a simple insulation sleeve or as the core of a ptfe lined hose for liquid cooling systems in supercomputers, the material ensures stable and reliable performance.

Extreme Thermal Stability

Heat management is a critical challenge in modern electronics. Our teflon tubing is engineered to withstand extreme thermal conditions. As highlighted in our product description, the raw PTFE material can handle temperatures as low as -200°C and as high as +260°C. This makes it perfect for cryogenic applications in quantum computing or high-heat environments near combustion engines.

For our specific braided assemblies, which offer enhanced structural integrity, the operational range remains robust. This thermal resilience ensures that the polytetrafluoroethylene tubing will not crack, melt, or deform, even when subjected to thermal cycling in soldering processes or aerospace maneuvers.

Mechanical Protection: The Braided Advantage

For applications requiring more than just electrical insulation, we offer the stainless steel braided teflon hose. In rugged industrial environments, cables and wires are at risk of abrasion, cuts, and crushing. The stainless steel braiding acts as a flexible armor, protecting the inner ptfe tube and the cables inside it from physical damage.

Despite this heavy-duty reinforcement, the product remains a flexible ptfe tubing solution. It allows for tight routing inside compact electronic enclosures without compromising the insulation barrier or the flow of cooling fluids.

Product Specifications

At Teflon X, we adhere to strict manufacturing standards. Below are the technical parameters for our High-Temperature Teflon Tube series:

| Brand | Teflon X |

| Material | Ptfe / polytetrafluoroethylene |

| ID of Tube (Inner Diameter) | 6.3 ~ 25.4mm |

| Temperature Range | -70 ~ +260°C |

| Features | Corrosion resistance, high and low temperature resistance, high pressure resistance, soft |

Global Compliance and Safety

We understand that the electronics industry is governed by strict regulations. Our ptfe teflon tubing is fully RoHS-compliant, ensuring it contains no hazardous substances such as lead or mercury. Furthermore, our manufacturing processes align with UL-certification standards for flammability and safety. When you specify a ptfe lined hose from Teflon X, you are choosing a product that meets global requirements for safety and environmental responsibility.

Why Choose Teflon X?

1. Expert Manufacturing: As a dedicated ptfe tube manufacturer, we have the expertise to produce tubing with consistent wall thickness and concentricity, vital for high-voltage insulation.

2. Custom Solutions: Whether you need a simple insulating sleeve or a complex stainless steel braided teflon hose for liquid cooling, we can customize lengths and diameters (ID 6.3mm – 25.4mm).

3. Reliability: Our teflon tubing is tested to ensure it remains “soft” and flexible while providing maximum durability.

Contact Us

Ensure the longevity and safety of your electronic systems with high-performance polytetrafluoroethylene tubing. Contact the experts at Teflon X today.

Email: allison.ye@teflonx.com

Website: https://teflonx.com/

Contact Page: Get a Quote Today

Reviews

There are no reviews yet.