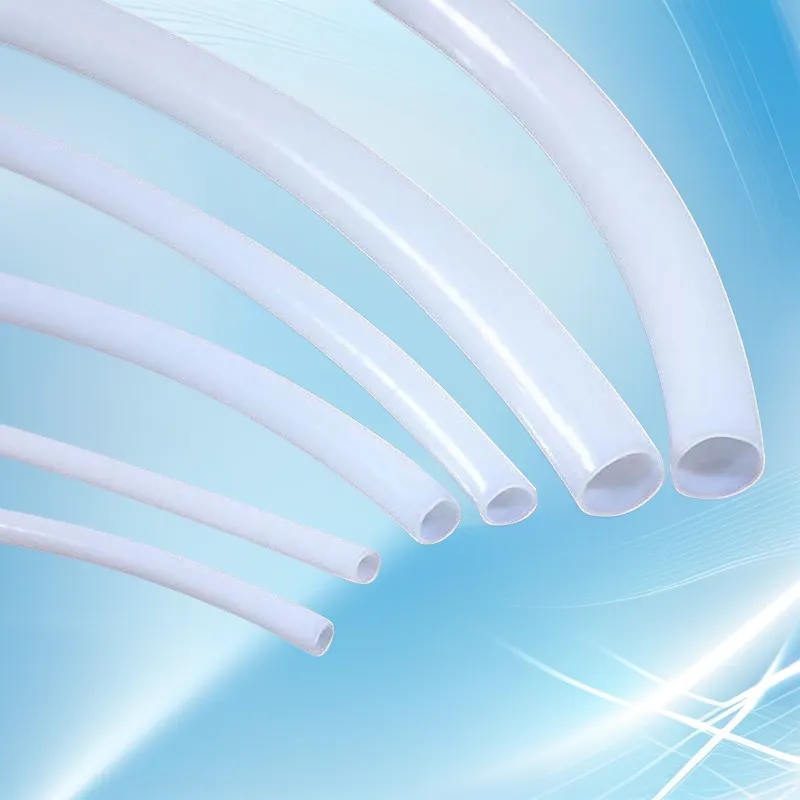

Low-Friction PTFE Tube | Energy-Efficient Material Transport Solutions

Welcome to Teflon X, your trusted partner for high-efficiency industrial fluid and material transfer. In the world of manufacturing and processing, friction is the enemy of efficiency. It causes pressure drops, increases energy consumption, and leads to equipment wear. Our Low-Friction PTFE Tube is engineered to combat these challenges directly. As a specialized ptfe tube manufacturer, we have developed a solution that drastically reduces fluid resistance, optimizing your systems for maximum performance and cost savings.

Whether you are designing pneumatic conveying systems for powders or pumping highly viscous liquids like adhesives or resins, the surface properties of your tubing matter. Our ptfe teflon tubing offers an ultra-smooth inner wall that revolutionizes material transport, ensuring that your operations run smoother, faster, and more economically.

The Science of Efficiency: Reducing Energy by 20%

The standout feature of our polytetrafluoroethylene tubing is its incredibly low coefficient of friction, rated at just 0.04. To put this in perspective, it is one of the slipperiest solid materials in existence—comparable to wet ice on wet ice. In practical applications, this means that fluids and granular materials slide through the ptfe tube with minimal resistance.

For industrial pumps and compressors, this reduction in resistance is significant. By switching to our low-friction ptfe lined hose, facilities can reduce the energy required to move materials by up to 20%. This not only lowers your monthly utility bills but also reduces the mechanical load on your pumps, extending their operational lifespan and reducing maintenance costs.

Ideal for Viscous Liquids and Powder Handling

Handling sticky, viscous materials or fine powders often leads to clogs and buildup in standard piping. Our flexible ptfe tubing eliminates this issue. The non-stick surface prevents materials from adhering to the tube walls. This is particularly beneficial for:

- Viscous Fluids: Paints, glues, and food pastes flow freely without narrowing the effective diameter of the tube over time.

- Pneumatic Conveying: Powders and granules are transported efficiently without clumping or blocking the line.

- Sanitary Applications: The lack of buildup means there are fewer places for bacteria or contaminants to hide, making cleaning cycles faster and more effective.

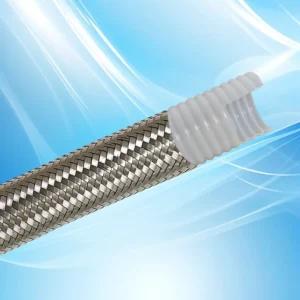

Reinforced for Durability: Stainless Steel Braided Options

While low friction is essential for flow, industrial environments also demand physical durability. That is why we integrate our low-friction liner into a robust stainless steel braided teflon hose. The external stainless steel braid provides critical reinforcement, allowing the hose to withstand high internal pressures and external physical abuse.

This braided design ensures that while the inner teflon tubing facilitates smooth flow, the outer layer protects against abrasion, kinking, and impact. This combination makes our product ideal for dynamic applications where the hose may be dragged, bent, or subjected to vibration.

Product Specifications

Teflon X provides high-performance tubing that meets rigorous technical standards. Below are the specific parameters for our Low-Friction PTFE Tube series:

| Brand | Teflon X |

| Material | Ptfe / polytetrafluoroethylene |

| ID of Tube (Inner Diameter) | 6.3 ~ 25.4mm |

| Temperature Range | -70 ~ +260°C |

| Features | Corrosion resistance, high and low temperature resistance, high pressure resistance, soft |

Anti-Static Solutions for Safety

In pneumatic conveying, the friction of dry powders moving at high speeds can generate static electricity. If uncontrolled, this can lead to dangerous sparking or dust explosions. To address this, Teflon X offers custom anti-static coatings for our ptfe tube products. By incorporating conductive carbon black into the PTFE matrix, we can dissipate static charge safely, ensuring compliance with safety regulations in hazardous environments.

Thermal and Chemical Resilience

Beyond its low-friction properties, our polytetrafluoroethylene tubing retains the legendary chemical and thermal resistance of PTFE. It operates flawlessly in temperatures ranging from -70°C to +260°C, making it suitable for transporting hot resins or cryogenic fluids. Furthermore, it is chemically inert, ensuring it will not react with aggressive solvents or acids.

Why Choose Teflon X?

1. Efficiency Focused: Our engineering centers on reducing your operational costs through superior material science.

2. Customization: From standard sizes (ID 6.3mm – 25.4mm) to custom anti-static blends, we tailor our ptfe teflon tubing to your needs.

3. Quality Assurance: As a premier ptfe tube manufacturer, every batch is tested to ensure a consistent friction coefficient and wall thickness.

Contact Us for Energy-Saving Solutions

Ready to reduce energy consumption and improve flow rates in your facility? Upgrade to the Low-Friction PTFE Tube from Teflon X. Contact our team today for a consultation.

Email: allison.ye@teflonx.com

Website: https://teflonx.com/

Contact Page: Get a Quote Here

Reviews

There are no reviews yet.