Low-Friction Skived Teflon Film for Aerospace & Automotive Components

Welcome to Teflon X, your specialized partner for advanced engineering materials. We are proud to introduce our high-performance Low-Friction Skived Teflon Film, a material meticulously designed to meet the rigorous standards of the aerospace and automotive sectors. By combining lightweight construction with extreme thermal resilience, our ptfe skived film serves as a critical component in next-generation engines, fuel systems, and high-voltage electronics.

What is Low-Friction Skived PTFE?

Skived film is created through a precision shaving process of a sintered Polytetrafluoroethylene (PTFE) billet. This manufacturing technique allows for the creation of incredibly thin, continuous sheets with a uniform molecular structure. The result is a skived ptfe material that maintains high tensile strength and flexibility while offering the lowest coefficient of friction of any solid material.

At Teflon X, our skived teflon films are engineered to reduce drag and wear in dynamic mechanical systems, making them indispensable for industries where efficiency and longevity are paramount.

Engineered for Aerospace and Automotive Excellence

Modern transport relies on materials that can withstand harsh environments without adding unnecessary weight. Our ptfe skived solution offers distinct advantages:

- Extreme Temperature Resistance: Capable of continuous operation up to +260°C (500°F), this skived film maintains its structural integrity in jet engines and high-performance automotive powertrains.

- Weight Reduction: The exceptional strength-to-weight ratio of our film aids in the overall lightweighting of aircraft and vehicles, contributing to better fuel efficiency.

- Superior Dielectric Properties: Functioning as a high-grade insulator, it is essential for protecting sensitive avionics and electric vehicle (EV) battery systems from high-voltage arcs.

- Chemical Inertness: The film is impervious to aviation fuels, hydraulic fluids, and automotive oils, preventing corrosion and degradation in fuel lines and tank liners.

Key Applications

The versatility of our ptfe skived film allows it to be deployed across various critical applications:

1. Automotive & Aerospace Mechanics

The low-friction surface is ideal for lining control cables, fuel hoses, and sliding bearings. It significantly reduces wear and tear in moving parts, extending the maintenance intervals for aircraft and vehicles.

2. Electrical Insulation

Due to its high dielectric strength, our skived ptfe is widely used as an insulating film for high-frequency capacitors, flexible printed circuit boards (PCBs), and wire wrapping in aerospace instrumentation.

3. Industrial Manufacturing

Beyond vehicles, this material is used in conveyor belts requiring heat resistance and non-stick properties, ensuring smooth operation in manufacturing plants.

Technical Specifications

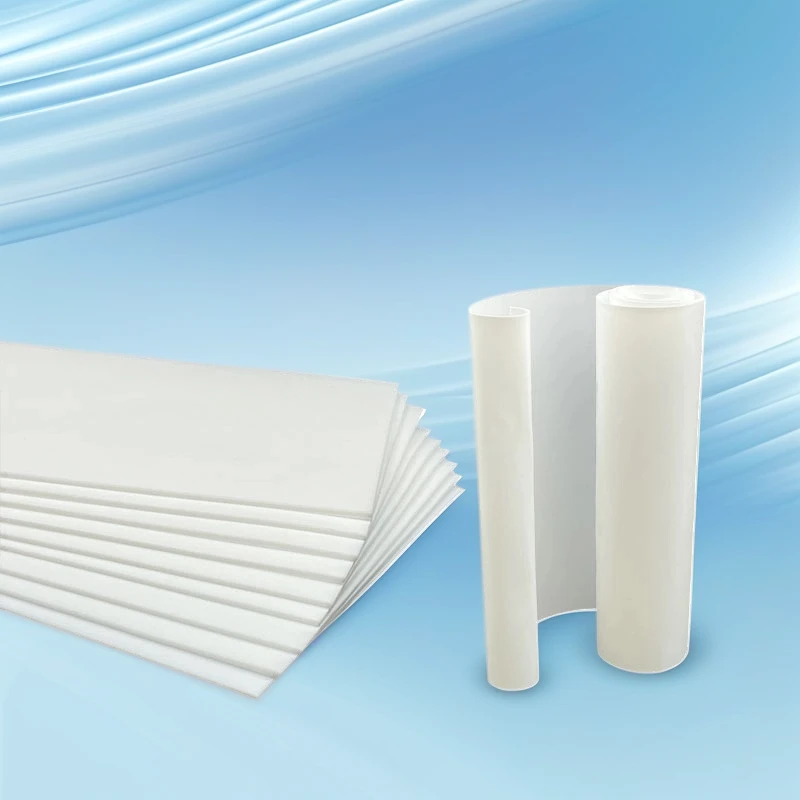

We provide skived teflon films in a variety of thicknesses and widths to suit specific engineering blueprints. Below are the standard technical parameters for our aerospace-grade film.

| Property | Typical Value |

|---|---|

| Material Composition | Virgin PTFE (Polytetrafluoroethylene) |

| Service Temperature | -200°C to +260°C |

| Melting Point | 327°C |

| Thickness Range | 0.025mm – 3.0mm (Customizable) |

| Density | 2.15 – 2.20 g/cm³ |

| Tensile Strength | ≥ 25 MPa |

| Elongation at Break | ≥ 250% |

| Dielectric Strength | ≥ 45 kV/mm (depending on thickness) |

| Friction Coefficient | < 0.05 (Static & Dynamic) |

| Flammability | UL94 V-0 (Non-flammable) |

Quality Assurance at Teflon X

In the aerospace and automotive industries, material failure is not an option. At Teflon X, our manufacturing process includes rigorous quality testing. We ensure that every roll of ptfe skived tape is free from pinholes and defects that could compromise dielectric performance or barrier integrity.

We also offer etched versions of our skived film to allow for bonding to other surfaces, such as steel or rubber, expanding its utility in composite structures.

Contact Our Engineering Team

Are you looking for a reliable supplier of high-performance skived teflon? Contact Teflon X today to discuss your specifications or request a sample of our aerospace-grade materials.

Email: allison.ye@teflonx.com

Contact Page: Get a Quote

Website: https://teflonx.com/

Reviews

There are no reviews yet.