PTFE Teflon Hose for Aerospace | Lightweight Fuel & Coolant Lines

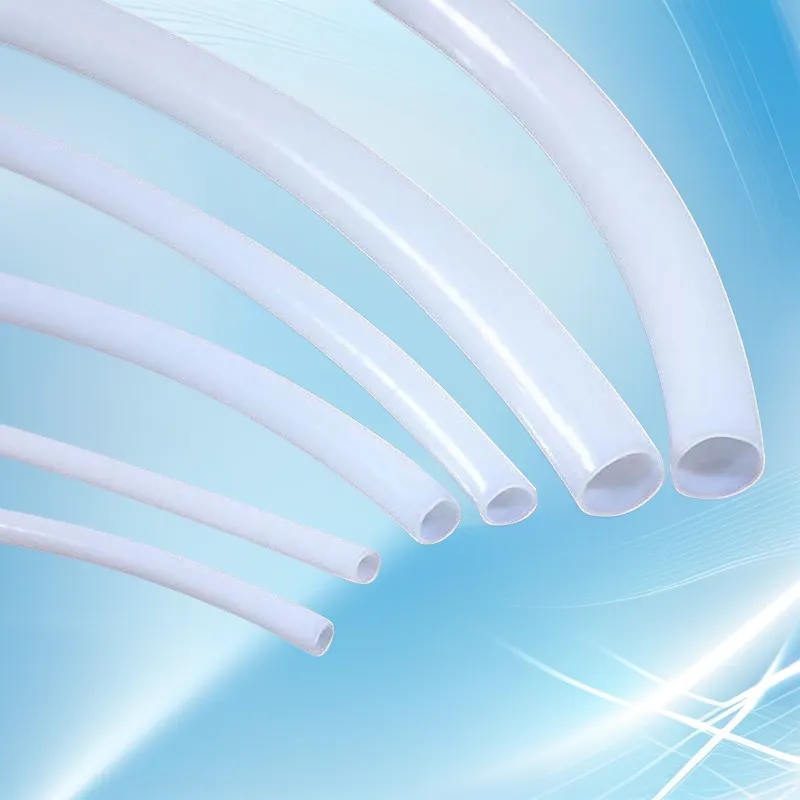

Welcome to Teflon X, a premier global ptfe tube manufacturer dedicated to advancing aerospace engineering. In an industry where every gram of weight matters and safety is absolute, standard fluid transfer systems are simply not enough. Our aerospace-grade PTFE Teflon Hose is engineered to deliver lightweight, high-performance solutions for fuel lines, hydraulic systems, and coolant circuits. By combining advanced material science with precision manufacturing, we provide tubing that meets the rigorous demands of modern aviation.

From commercial airliners to private jets and drones, the need for reliable fluid transfer under extreme conditions is universal. Our Teflon Braided Pipe offers the perfect balance of flexibility, weight reduction, and extreme durability, ensuring that your aircraft systems operate flawlessly at any altitude.

The Aerospace Advantage: Weight Reduction and Efficiency

One of the primary reasons aerospace engineers choose our polytetrafluoroethylene tubing over traditional rubber or metal piping is weight. PTFE is significantly lighter than comparable rubber hoses reinforced with heavy fabric or steel layers. In aviation, reducing weight translates directly to improved fuel efficiency and increased payload capacity.

Despite being lightweight, our ptfe teflon tubing does not compromise on strength. When paired with our high-tensile braiding options, it offers a superior strength-to-weight ratio. This allows designers to route fuel and hydraulic lines through complex airframes without adding unnecessary bulk, optimizing the overall architecture of the aircraft.

Withstanding Vibration and Thermal Cycling

Aircraft engines and airframes are subjected to constant vibration and rapid temperature changes during flight. A standard hose can fatigue, crack, or delaminate under these stresses. Our stainless steel braided teflon hose is specifically designed to combat these issues. The external stainless steel braid performs two critical functions:

- Vibration Dampening: The braided mesh absorbs mechanical vibration, preventing it from transferring to the inner ptfe tube and causing stress fractures.

- Thermal Expansion Control: As the fluid temperature changes, the braid restricts the radial expansion of the tube, maintaining consistent pressure and flow.

This construction ensures that our flexible ptfe tubing remains reliable whether the aircraft is sitting on a scorching runway or cruising at 30,000 feet in sub-zero temperatures.

Product Specifications

Teflon X adheres to the highest standards of quality control. Below are the technical parameters for our aerospace-grade tubing, highlighting the performance metrics essential for flight safety.

| Brand | Teflon X |

| Material | Ptfe / polytetrafluoroethylene |

| ID of Tube (Inner Diameter) | 6.3 ~ 25.4mm |

| Temperature Range | -70 ~ +260°C |

| Features | Corrosion resistance, high and low temperature resistance, high pressure resistance, soft |

Chemical Immunity for Critical Fluids

Aerospace fluids, including jet fuel, Skydrol (hydraulic fluid), and de-icing agents, are chemically aggressive. They can rapidly degrade conventional materials. However, the ptfe lined hose from Teflon X is chemically inert. The core polytetrafluoroethylene tubing is impervious to virtually all chemicals, ensuring that there is no leaching, swelling, or corrosion inside the line.

This property is vital for maintaining the purity of fuel systems and preventing blockages in sensitive hydraulic actuators. The smooth inner surface of the ptfe tube also minimizes pressure drops, ensuring that pumps operate efficiently and fluids reach their destination without delay.

Compliance and Safety Standards

Safety is non-negotiable in aerospace. Our manufacturing processes are aligned with AS/EN9100 standards, ensuring total traceability and quality assurance. The teflon tubing undergoes rigorous testing for pressure bursting, impulse capability, and leakage before it leaves our facility. When you specify a Teflon X product, you are choosing a component that contributes to the overall airworthiness and safety of the vehicle.

Why Partner with Teflon X?

1. Aerospace Expertise: We understand the unique challenges of flight. As a specialized ptfe tube manufacturer, we can assist in designing custom assemblies that fit tight engine nacelles or landing gear bays.

2. Custom Sizing: With an Inner Diameter (ID) range of 6.3mm to 25.4mm, we cover the majority of fuel and coolant line requirements for general and commercial aviation.

3. Extreme Temperature Resilience: Our flexible ptfe tubing operates effectively from -70°C to +260°C, handling the most extreme environmental swings found in aviation.

Contact Us for Engineering Support

Elevate your aerospace designs with the reliability of high-performance stainless steel braided teflon hose. Contact the engineering team at Teflon X today to discuss your specific requirements.

Email: allison.ye@teflonx.com

Website: https://teflonx.com/

Contact Page: Submit Your Inquiry Here

Reviews

There are no reviews yet.