Introduction

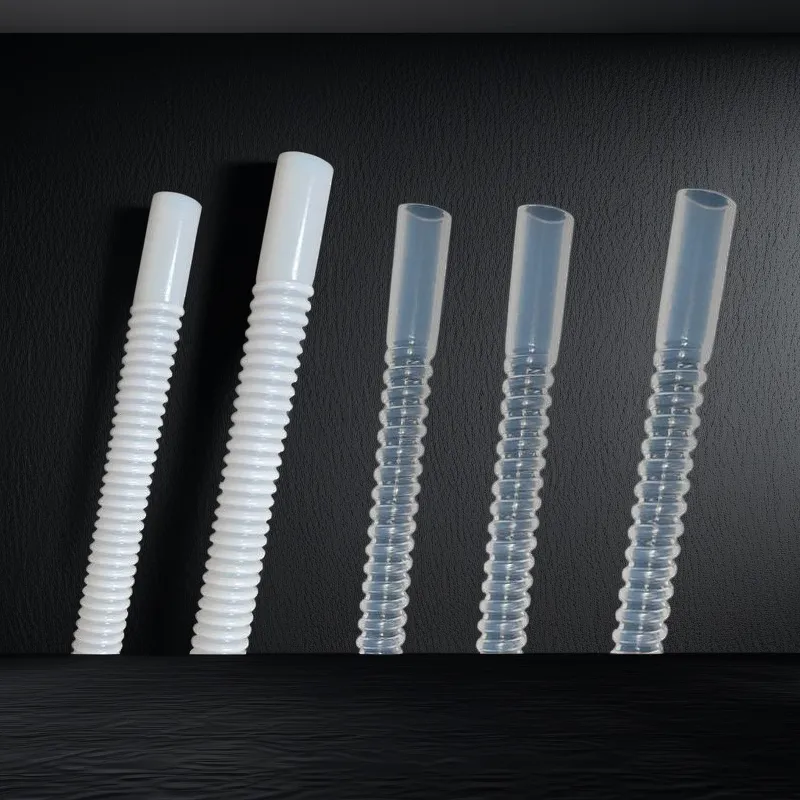

Water treatment systems are critical for ensuring clean, safe water in industrial, municipal, and commercial applications. Selecting the right components for these systems is essential to ensure efficiency, durability, and compliance with stringent regulations. Among these components, PTFE hose stands out as a superior choice due to its exceptional chemical resistance, flexibility, and longevity. Whether used in water treatment systems, chemical processing, or fuel transfer, PTFE corrugated fuel hose and PTFE lined bellow offer unmatched performance.

Why PTFE Hose Excels in Water Treatment Systems

PTFE (Polytetrafluoroethylene) is a fluoropolymer known for its non-stick properties, high thermal stability, and resistance to corrosive chemicals. These characteristics make PTFE hose an ideal choice for water treatment systems, where exposure to aggressive chemicals, high temperatures, and varying pressures is common.

Key Benefits of PTFE Hose

- Chemical Resistance: PTFE hoses withstand a wide range of chemicals, including acids, bases, and solvents used in water treatment processes. According to a 2021 study by the American Water Works Association (AWWA), chemical compatibility is a top consideration for material selection in water treatment facilities.

- Temperature Tolerance: PTFE hoses operate effectively in temperatures ranging from -70°C to 260°C (-94°F to 500°F), making them suitable for both hot and cold water treatment applications.

- Flexibility and Durability: The corrugated design of PTFE corrugated fuel hose enhances flexibility, allowing it to handle dynamic movements without kinking or cracking. This is critical in systems requiring frequent maintenance or adjustments.

- Non-Stick Surface: The low-friction surface of PTFE prevents scaling and buildup, reducing maintenance costs and ensuring consistent flow rates.

- Compliance with Standards: PTFE hoses meet FDA, USP Class VI, and NSF standards, ensuring they are safe for potable water applications.

Comparison of PTFE Hose vs. Other Materials

| Material | Chemical Resistance | Temperature Range | Flexibility | Cost |

|---|---|---|---|---|

| PTFE Hose | Excellent | -70°C to 260°C | High | Moderate |

| Rubber Hose | Moderate | -40°C to 100°C | Moderate | Low |

| Stainless Steel | Good | -200°C to 600°C | Low | High |

| PVC Hose | Poor | 0°C to 60°C | High | Low |

Source: Data compiled from industry standards and manufacturer specifications (2023).

The table above highlights why PTFE hose outperforms alternatives like rubber or PVC in demanding water treatment environments.

Applications of PTFE Hose in Water Treatment

PTFE hoses, including PTFE corrugated fuel hose and PTFE lined bellow, are versatile and widely used in various water treatment processes. Below are some key applications:

1. Chemical Dosing Systems

Water treatment often involves dosing chemicals like chlorine, sodium hydroxide, or sulfuric acid to purify water. PTFE hose ensures safe and reliable transfer of these chemicals without degradation.

2. Filtration Systems

In reverse osmosis (RO) and ultrafiltration systems, PTFE lined bellow provides a flexible, corrosion-resistant connection between components, maintaining system integrity under high pressure.

3. Wastewater Treatment

Wastewater treatment plants handle aggressive chemicals and fluctuating temperatures. PTFE corrugated fuel hose is used to transport sludge, chemicals, and treated water, ensuring long-term performance.

4. Potable Water Systems

For drinking water applications, PTFE hoses comply with stringent safety standards, ensuring no contamination occurs during water transfer.

Case Study: A 2022 report by the Water Environment Federation (WEF) highlighted a municipal water treatment plant in California that reduced maintenance costs by 15% after switching to PTFE hoses for chemical dosing lines.

How PTFE Hoses Enhance System Efficiency

Reduced Maintenance Costs

The non-stick and corrosion-resistant properties of PTFE hose minimize blockages and extend service life. A 2020 study by the International Water Association (IWA) found that facilities using PTFE-based components reported 20% lower downtime compared to those using rubber or PVC hoses.

Improved Flow Rates

The smooth inner surface of PTFE lined bellow reduces friction, ensuring consistent flow rates and minimizing energy consumption in pumping systems.

Environmental Benefits

PTFE hoses are recyclable and have a longer lifespan than alternatives, reducing waste and supporting sustainable water treatment practices.

Choosing the Right PTFE Hose for Your Water Treatment System

When selecting a PTFE hose for your water treatment system, consider the following factors:

- Hose Type: Choose between smoothbore PTFE hoses for high-flow applications or PTFE corrugated fuel hose for flexibility in tight spaces.

- Pressure Rating: Ensure the hose can handle the system’s maximum pressure. Most PTFE hoses support pressures up to 3000 PSI, but check manufacturer specifications.

- End Fittings: Select compatible fittings (e.g., stainless steel or PTFE-lined) to prevent leaks and ensure chemical compatibility.

- Certifications: Verify compliance with industry standards like NSF/ANSI 61 for potable water or ASME BPE for pharmaceutical-grade water treatment.

Pro Tip: Consult with a certified supplier to customize PTFE lined bellow or hoses to match your system’s specific requirements.

High-Performance PTFE Corrugated Fuel Hose for Fuel Systems

PTFE corrugated fuel hose is ideal for high-performance fuel systems in automotive and aerospace. This Teflon fuel hose resists corrosive fuels and extreme temperatures. Its corrugated fuel tube design ensures flexibility, durability, and minimal flow resistance for efficient, long-term operation.

FAQ: PTFE Hose in Water Treatment Systems

1. Why is PTFE hose preferred over rubber for water treatment?

PTFE hose offers superior chemical resistance, a wider temperature range, and a non-stick surface, making it more durable and efficient than rubber hoses in harsh water treatment environments.

2. Can PTFE hoses be used for potable water?

Yes, PTFE hoses that meet FDA, USP Class VI, and NSF/ANSI 61 standards are safe for potable water applications, ensuring no contamination.

3. How long do PTFE hoses last in water treatment systems?

With proper maintenance, PTFE hoses can last 5-10 years or more, depending on the application and operating conditions, as per industry reports from the AWWA (2021).

Conclusion

PTFE hose, including PTFE corrugated fuel hose and PTFE lined bellow, is a game-changer for water treatment systems. Its unmatched chemical resistance, temperature tolerance, and flexibility make it the ideal choice for chemical dosing, filtration, wastewater treatment, and potable water applications. By reducing maintenance costs, improving flow rates, and supporting sustainability, PTFE hoses deliver long-term value to water treatment facilities.

Ready to upgrade your water treatment system with high-performance PTFE hoses? Contact us today for a customized solution and a competitive quote. Let’s work together to ensure clean, safe water for your operations!