If you are in the business of building commercial vehicles, you know the headache I’m talking about. You design a solid exhaust system, everything looks great on the CAD model, and then six months later, the warranty claims start rolling in. The culprit? Usually that innocent-looking little tube carrying the Diesel Exhaust Fluid (DEF).

AdBlue—or urea solution, whatever you prefer to call it—is deceptive. It looks like water, but it’s a quiet killer of standard rubber and even some lower-grade plastics.

I’ve spent years digging into the guts of SCR systems (Selective Catalytic Reduction), and I’ve seen what happens when manufacturers try to cut corners on urea injection lines. It’s not pretty. Crystallization, swelling, cracking… it’s a mess.

Today, I’m not going to bore you with a textbook lecture. I’m going to tell you why PTFE hoses for AdBlue are basically the only option if you actually care about long-term reliability, and I’ll back it up with the chemistry and some hard truths about alternative materials.

The “Secret” Chemistry That Destroys Your Hoses

Most people think AdBlue is just 32.5% urea and water. Simple, right? Well, yeah, until it gets hot. And in an engine bay, everything is hot.

When AdBlue hoses are subjected to the heat near the exhaust manifold, a chemical reaction kicks off. We call it hydrolysis. If your tubing material isn’t ready for this, it permeates the wall of the hose.

Here is what is happening on a molecular level. I’ll keep the math simple so you can see why this matters.

The Reaction:

(NH2)2CO [Urea] + H2O [Water] -> 2NH3 [Ammonia] + CO2 [Carbon Dioxide]

See that NH3? That’s Ammonia.

Ammonia is aggressive. It loves to attack elastomers. If you are using EPDM (ethylene propylene diene monomer) rubber that hasn’t been peroxide-cured specifically for this, the ammonia molecules are going to worm their way into the polymer chains. The hose swells up. It gets soft. Then, it bursts.

I remember inspecting a fleet of delivery trucks in 2019. They used a cheap polyamide blend for their urea injection lines. The ammonia didn’t just break the hose; it permeated through the tube wall and corroded the electrical connectors next to the hose. The hose looked fine on the outside, but the sensors failed. That is the kind of nightmare we are trying to avoid.

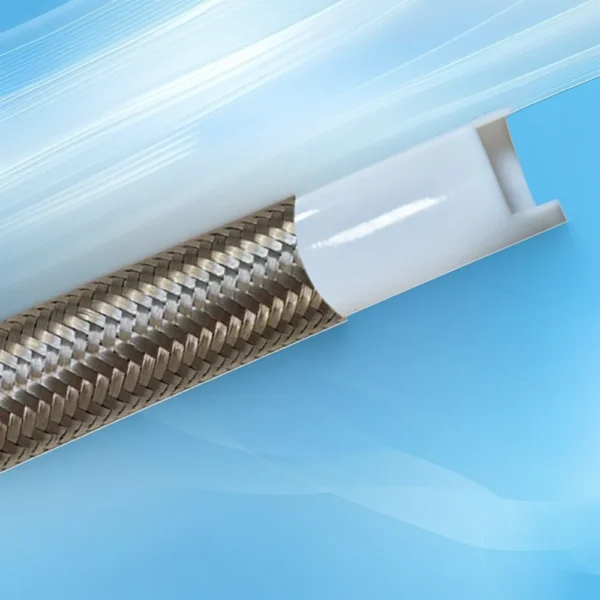

Braided Fuel Line – Anti Static PTFE Hose with Stainless Steel Reinforcement

Upgrade to our braided fuel line for enhanced safety and performance. The anti static PTFE hose dissipates static buildup, preventing explosions. This conductive braided tube features stainless steel reinforcement for added strength. It’s also a great option as a flexible gas line.

Why PTFE is the Heavyweight Champion here

This is where Teflon X comes into the picture. Polytetrafluoroethylene (PTFE) doesn’t care about ammonia. It doesn’t care about urea. Honestly, you could run much nastier stuff through it and it wouldn’t blink.

1. Chemical Inertness

The carbon-fluorine bond in PTFE is one of the strongest in organic chemistry. It’s like a fortress. When AdBlue breaks down into ammonia, the PTFE wall acts like a shield. There is zero reaction.

I’ve soaked our PTFE Tubes in boiling urea solution for 500 hours just to see what would happen. Result? No weight change. No swelling. Nothing.

2. The Temperature Factor

Commercial trucks have engine compartments that are getting hotter because of tighter emission standards (Euro 6, EPA 2010, and newer).

- Nylon 12 (PA12): Good until about 100°C (212°F). After that, it gets brittle.

- EPDM: Good until about 120°C-140°C, but watch out for that chemical attack.

- PTFE: Handles up to 260°C (500°F) easily.

If your SCR systems have lines running near the turbo or the exhaust downpipe, using Nylon is a gamble I wouldn’t take.

Comparison: PTFE vs. The Others

Let’s look at the data. I threw this table together to make it easy to compare.

| Feature | Teflon X PTFE | Polyamide 12 (PA12) | EPDM Rubber |

|---|---|---|---|

| Chemical Resistance (Urea/Ammonia) | Excellent | Good (but absorbs moisture) | Fair (Swells over time) |

| Max Operating Temp | 260°C | 100°C | 130°C |

| Permeability | Extremely Low | Moderate | High |

| Flexibility | High (with braiding) | Rigid | High |

| Risk of Crystallization Clogging | Low (Non-stick surface) | Medium | High (Rough surface) |

The Crystallization Headache

Here is something the spec sheets usually don’t tell you. AdBlue crystallizes when it dries out or gets cold. White, chalky crystals.

If you use a hose with a rough inner surface (like rubber), those crystals stick. They build up. Eventually, you restrict the flow, the doser pump burns out, and the Check Engine light turns on.

Because PTFE is famously “non-stick” (think frying pans, but industrial grade), the urea solution slides right through. Even if the truck sits for a week in freezing temps and crystals form, as soon as the heater kicks in and flow starts, those crystals slide off the PTFE wall and dissolve back into the solution. It’s a self-cleaning mechanism for your chemical resistant tubing.

Real Talk: A Case Study (Anonymous)

I want to share a story about a client—let’s call them “Big Rigid Trucks Inc.”

They were having a massive issue with their Class 8 trucks. The AdBlue hoses were routed weirdly close to the EGR cooler. The radiant heat was spiking to around 130°C. Their existing PA12 tubes were becoming brittle and cracking within 18 months.

The warranty cost? About $450 per truck per repair, factoring in tow trucks, labor, and parts.

They switched to a customized Teflon X PTFE hose assembly with a stainless steel braid for protection.

The Result:

- Initial Cost: The PTFE hose cost about 15% more than the PA12 tube.

- Warranty Claims: Dropped to near zero for that specific part over the next 3 years.

- Savings: They saved hundreds of thousands in warranty labor, not to mention their brand reputation improved because drivers weren’t getting stranded.

Sometimes paying an extra dollar on the hose saves you a thousand dollars in the field. It’s simple math.

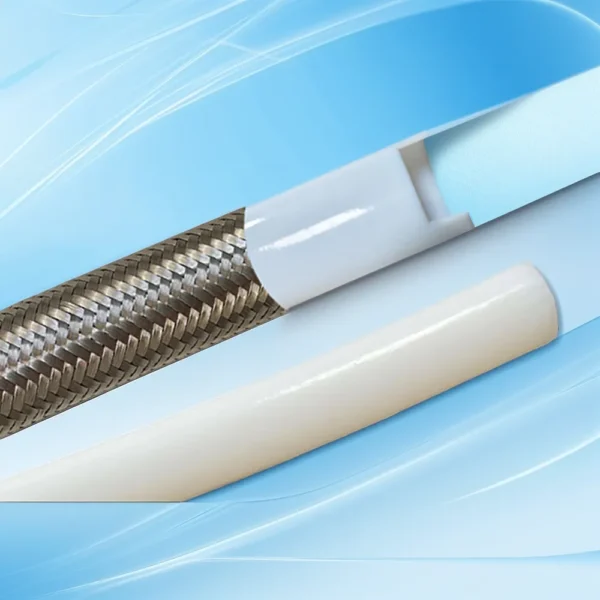

Custom PTFE Teflon Tubing | Corrosion-Proof Hose for Industrial Cooling

Custom PTFE Teflon tubing is engineered for industrial cooling systems, offering chemical inertness and thermal stability. Metal-braided options enhance pressure resistance in liquid cooling circuits for machinery and power electronics. Available in FDA-compliant grades for diverse sectors.

Technical Specs You Should Demand

When you are sourcing these hoses, don’t just ask for “PTFE.” There is garbage PTFE out there—recycled stuff that cracks if you look at it wrong.

You need virgin resin. Paste extruded.

Here is what you should be putting in your RFQ (Request for Quote):

- Material: Virgin Paste Extruded PTFE (Polytetrafluoroethylene).

- Wall Thickness: Minimum 1.0mm for structural integrity under pressure spikes.

- Reinforcement: 304 Stainless Steel braid (single or double depending on pressure).

- Burst Pressure: Should exceed 4x your working pressure. For AdBlue dosing, working pressure is usually around 5-9 bar, but you want a hose rated for much higher to handle the spikes.

- Permeability: Ask for low-permeability grades if the lines run through the cab (you don’t want the driver smelling ammonia).

At Teflon X, we control the sintering process strictly. If you don’t bake the PTFE tube at the exact right temperature curve, the crystallinity of the polymer is wrong, and it won’t flex properly. It’s an art as much as a science.

Installation Mistakes That Ruin Good Hoses

Even the best urea injection lines fail if you install them like an idiot. Sorry, but I see this all the time on assembly lines.

1. The Twist:

When tightening the fitting, the assembler lets the hose twist. This puts torsion on the PTFE core. Once the system heats up and pressure builds, that torsion force rips the tube open. Always use two wrenches—one to hold the hose, one to turn the nut.

2. The Bend Radius:

PTFE is flexible, but it’s not magic. If you kink it, you compromise the wall. Check the minimum bend radius spec. If you need a tighter turn, use an elbow fitting, don’t force the hose.

3. Clamping too tight:

Don’t crush the hose with zip ties or metal clamps. PTFE can cold flow (deform) under constant pressure. If you squash it, you restrict the flow.

Why Electric Heating Matters

In colder climates (hello, Canada and Northern Europe), AdBlue freezes at -11°C (12°F). When it freezes, it expands.

Standard PTFE is strong enough to handle this expansion without splitting, unlike rigid metal lines. However, most OEMs wrap the hose in an electrically heated wire (heated lines).

Our chemical resistant tubing is compatible with these heating elements. The thermal conductivity of PTFE allows the heat to penetrate and thaw the urea, but the high melting point means the heater wire won’t melt through the hose wall if the controller glitches and gets too hot.

My Controversial Take: Stop Using PA12

Look, PA12 (Nylon) has been the industry standard for a long time because it’s cheap and easy to thermoform. But in my opinion, it’s obsolete for modern Euro 6 and Tier 4 Final engines. The thermal loads are just too high.

I’ve debated this with engineers at trade shows. They say, “But PTFE is harder to route.” Maybe. But would you rather spend an extra 10 minutes on routing design or replace the line every two years?

If you are building a machine meant to last a million miles, PA12 is a weak link. Stick with PTFE.

Flexible PTFE Tubing | Non-Stick Teflon Tube for Food & Pharma Industries

Flexible PTFE tubing features a non-stick surface, meeting strict hygiene standards for food-grade oil transfer and pharmaceutical sterile filtration. Its bend tolerance and thermal stability (-200°C to +260°C) ensure reliable performance in dynamic environments. Custom lengths and braiding options available.

Summary

To wrap this up—AdBlue systems are nasty environments. You have corrosive ammonia, high heat from the exhaust, and freezing temperatures in winter.

Your AdBlue hoses are the veins of the emissions system. If they burst, the truck stops.

Using high-quality Teflon X PTFE ensures:

- Total immunity to chemical attack.

- Resistance to heat up to 260°C.

- Self-cleaning flow to prevent crystallization.

If you are currently seeing failure rates on your SCR lines, it’s probably not a “bad batch” of rubber. It’s just the wrong material.

FAQ

Q1: Can I use standard hydraulic hoses for AdBlue?

Absolutely not. Standard hydraulic hoses are usually made of Nitrile or Neoprene rubber. The urea solution will extract plasticizers from the rubber, contaminating the SCR catalyst (which costs thousands to replace) and the hose will eventually swell and fail. Only use materials rated for urea, like PTFE or EPDM (peroxide cured).

Q2: What is the lifespan of a PTFE hose in an SCR system?

Ideally, it should last the life of the vehicle. Unlike rubber, PTFE doesn’t age or degrade from UV light or oxidation. Unless it is mechanically damaged (rubbing against a frame rail) or installed incorrectly (twisted), a Teflon X hose can easily last 10+ years.

Q3: Is the stainless steel braid necessary for urea lines?

It depends on the location. If the hose is exposed to road debris or rubbing, yes, the braid is mandatory for protection. Also, if the dosing pressure is high, the braid keeps the PTFE from expanding. For low-pressure return lines inside a protected bundle, a naked PTFE tube might suffice, but we almost always recommend braiding for durability.

PTFE Tube Manufacturer | High-Temp Teflon Tubing for Chemical & Medical Use

PTFE Tube (Polytetrafluoroethylene Tubing) offers exceptional chemical resistance and thermal stability from -200°C to +260°C, making it ideal for corrosive fluid transfer in chemical processing and pharmaceutical applications. With a friction coefficient of 0.04 and non-stick properties, our PTFE tubing minimizes energy loss and ensures contamination-free operation. Customizable with stainless steel braiding for pressures up to 1.6 MPa.

Need to stop the corrosion?

If you are tired of dealing with warranty claims on your emission systems, let’s talk. At Teflon X, we don’t just sell hoses; we help you engineer the solution.

Check out our full range of PTFE Tubes to see what fits your specs.

Or better yet, send me the specs of the problem you’re trying to solve. You can reach us directly at our Contact Us page or shoot an email to Allison.Ye@teflonx.com. Let’s get your fleet running right.