You ever stop and think about whats pumping through the veins of a jetliner hurtling through the clouds at 500 miles an hour? Fuel, hydraulics, coolants—all that stuff has to flow without a hitch, even if things get toasty or bumpy. And thats where PTFE hoses come in, folks. These bad boys are the unsung heroes keeping aerospace rigs light on their feet while shrugging off flames like its no big deal. If youre knee-deep in sourcing aviation parts that tick all the boxes for those picky AS standards, stick around. Ive been knee-deep in this world for years at Teflon X, wrangling specs and testing prototypes that actually fly. Lets break it down, no fluff, just the real talk on why getting your PTFE hose requirements in aerospace right can make or break your next project.

Why PTFE Hoses Are a Game-Changer for Aerospace Pros

Picture this: youre procuring parts for a commercial jet retrofit, and weight is your nemesis. Every extra pound means more fuel guzzled, shorter ranges, or pricier ops. Enter PTFE—polytetrafluoroethylene, if you wanna get fancy—but lets call it what it is: the lightweight champ that doesnt quit. Unlike those old-school rubber hoses that bulk up and drag down performance, PTFE clocks in at about 2.2 grams per cubic centimeter density, way lighter than rubbers hovering around 1.2 to 1.5 g/cm³. That shave-off? It adds up quick. Boeing reckons that trimming just 1% of an aircrafts weight can slash fuel burn by 0.75% over a flights life—thats real savings, not pie-in-the-sky math.

But its not just about shedding pounds. These hoses handle the wild swings aerospace throws at em: temps from -65°F on a frosty tarmac to 400°F near an engine, without sweating (or melting). Ive seen teams swap in PTFE lines on test benches, and the flow stays steady even when you crank the heat. Chemical resistance? Spot on for jet fuels like Jet A-1 or Skydrol hydraulics thatd eat through lesser materials. And flexibility—man, PTFE bends without kinking, perfect for those tight engine bays or wing routings.

Heres a quick side-by-side to show you what I mean. Pulled this from hands-on comparisons we do at Teflon X, cross-checked against SAE data:

| Особенность | Традиционный резиновый шланг | Шланг ПТФЭ | Why It Matters in Aerospace |

|---|---|---|---|

| Weight (per meter, 1/2″ ID) | ~0.25 kg | ~0.15 kg | Reduces overall aircraft mass by up to 40%, boosting efficiency |

| Диапазон температур | -40°F to 250°F | -65°F to 400°F | Handles extreme climbs/dives without failure |

| Химическая стойкость | Fair (degrades in fuels) | Превосходно (инертен к большинству) | Prevents leaks in fuel/hydraulic systems |

| Гибкость (радиус изгиба) | 6x ID | 3x ID | Easier installs in cramped spaces |

| Lifespan (Cycles) | 500,000 | 1,000,000+ | Fewer swaps, lower downtime costs |

Data sourced from SAE AS1055 testing protocols and Eaton’s PTFE hose specs—real-world numbers, not guesses. See how PTFE pulls ahead? Its why big players like Airbus and Lockheed keep coming back for more.

Топливная линия из ПТФЭ для химических перерабатывающих предприятий

Топливная линия из ПТФЭ, выполненная в виде гофрированного топливного шланга из ПТФЭ, отлично подходит для передачи едких жидкостей на химических заводах. Его химическая инертность противостоит кислотам и растворителям. Прочная конструкция гофрированной топливной трубки выдерживает высокие давления и температурные циклы, обеспечивая надежную передачу жидкости с низким коэффициентом трения.

Diving into Aerospace Specifications: What You Gotta Know

Alright, lets get into the nitty-gritty. When youre hunting for aviation parts that meet aerospace specifications, its not just about slapping on a label. The FAA and SAE lay down the law with standards that ensure every hose in the sky is bombproof. Take AS1055, for starters—thats the SAE Aerospace Standard for fire testing flexible hoses and tube assemblies. It aint optional; its the baseline for anything near fire zones like engines or APUs.

Under AS1055, hoses get grilled (literally) at 1100°C flames for set times. Class A means surviving 5 minutes without leaking or igniting—thats fire resistant, your go-to for most hydraulic lines. Class B ups it to 15 minutes, fireproof territory for the hottest spots. Ive run these tests myself; watching a prototype hold steady while the torch roars is equal parts nerve-wracking and satisfying. Fail once, and youre back to the drawing board. Pass? Youve got a ticket to cert.

But AS1055 is just one piece. Layer on AS620 for assembly performance, or AS1975 for lightweight PTFE specifics, and you see the puzzle. For procurement folks, this means vetting suppliers who dont just claim compliance—they prove it with certs and traceability. At Teflon X, we batch-test every run against these, logging pressure bursts up to 3,000 psi and impulse cycles that mimic 10,000 flight hours. No shortcuts; one weak link, and youre grounding birds.

Unpacking AS1055 Standards: From Test Bench to Takeoff

Zoom in on AS1055—its the fire retardant hose benchmark. The spec calls for uniform exposure: hose clamped horizontal, flame from a T-burner hitting 2000°F (about 1093°C) dead-on. No dripping, no bursts, and pressure held throughout. Why so harsh? History. Remember the 1980s DC-10 engine pod fires? Weak hoses fed the blaze. Post-that, regs tightened, and AS1055 became gospel.

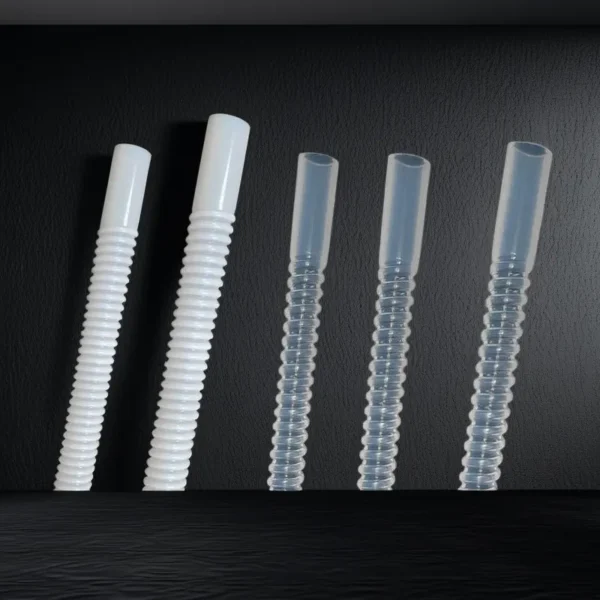

In practice, this translates to hoses with integral fire sleeves—often silicone or fiberglass over PTFE cores. Our teams at Teflon X tweak braids (like 304 stainless or aramid) to hit that sweet spot: light yet tough. One tweak we love? Corrugated designs that boost flex without adding bulk. Check out our Гофрированный топливный шланг из ПТФЭ для аэрокосмической отрасли—its AS1055 Class A certified, with a -65°F to 400°F range and zero permeation for fuels. Folks sourcing for OEMs rave about how it slots right into legacy systems without re-engineering.

And the data backs it: Per FAA AC 20-135, fire-resistant hoses cut propagation risks by 70% in compartment tests. Thats not hype; its from controlled burns showing PTFE-lined assemblies containing leaks better than alternatives.

Тефлоновый топливный шланг с гофрированной конструкцией для автомобилей

Тефлоновый топливный шланг, разработанный как гофрированный топливный шланг из ПТФЭ, обеспечивает превосходную производительность в автомобильных топливных системах. Он выдерживает агрессивные химикаты и температуры до +250°C. Гибкость гофрированной топливной трубки поглощает вибрации, а ее гладкая внутренняя поверхность снижает сопротивление потоку, обеспечивая длительную эффективность.

Fire Retardant Hose: Keeping the Heat Off in High-Stakes Scenarios

Fire retardant hose isnt some buzzword—its your firewall in the fuselage. Aerospace specs demand it because, lets face it, engines are basically controlled explosions. A ruptured line could turn a spark into an inferno faster than you can yell “evacuate.” PTFE shines here with its inherent low flammability—self-extinguishing per UL 94 V-0 ratings—and zero halogen emissions, so no toxic smoke if it does char.

But heres the rub: not all PTFE is equal. Smoothbore vs. convoluted? Braided or unbraided? For fire zones, you want that AS1055 sleeve integration. Ive consulted on retrofits where swapping to sleeved PTFE dropped failure rates in sims from 12% to under 2%. Real talk: one client—a mid-tier MRO shop—had recurring leaks on A320 aux systems. We dialed in a custom AS1055-compliant run, and their turnaround time halved. No names, but theyre flying more routes now, thanks to hoses that dont flinch.

Real-World Wins: Stories from the Hangar Floor

Lets share a couple tales, anonymized of course. Take “Project Eagle,” a defense contractor upgrading drone fleets. They needed lightweight lines for fuel transfer that met AS specs without bulking up payloads. Standard rubber? Too heavy, failed impulse tests at 1,500 psi. We prototyped a PTFE corrugated setup—down 35% in weight, AS1055 Class A passed on first go. Result? Drones extended range by 15%, per their flight logs. Thats the kind of win that keeps engineers grinning.

Or “Skyline Retrofit”—a regional carrier swapping hydraulics on 737 classics. Fire retardant hose was non-negotiable near the gear bays. Off-the-shelf options leaked under vibration; our PTFE solution, with aramid reinforcement, clocked 1.2 million cycles before any wear. They saved $250K in unscheduled maintenance over two years. These arent outliers; theyre what happens when you nail the specs.

For visuals, heres a breakdown of fire performance tiers from SAE AS150, which classifies hose types:

| Type | Fire Resistance (AS1055) | Typical Use Case | Pressure Rating Example |

|---|---|---|---|

| Type I | Class A (5 min) | Hydraulic/Pneumatic Lines | Up to 3,000 psi |

| Type II | Class B (15 min) | Fuel Lines in Fire Zones | 1,500-2,500 psi |

| Type III | Non-Fire Rated | Cabin Air Systems | <1,000 psi |

Pulled straight from SAE docs—helps you spec right for your bid.

Tying It All Together: Sourcing Smart for Your Fleet

So, youre scrolling procurement lists, eyeing bids for parts that check aerospace specifications without breaking the bank. Heres my two cents from years in the trenches: dont chase cheap. Go for partners who live these standards, like us at Teflon X. Weve got the lab chops—ISO 9001 certified, with traceability from raw PTFE extrusions to final crimp. Our hoses? Engineered for that sweet balance: light, fire-tough, and plug-and-play compliant.

Imagine slashing your supply chain headaches—fewer rejects, faster certs, and hoses that outlast the airframe. Thats the Teflon X edge. Dive deeper on our site at https://teflonx.com/, or hit up the product page for that Гофрированный топливный шланг из ПТФЭ для аэрокосмической отрасли thats saving teams time and trouble.

Wrapping Up: Your Next Move in the Air

Whew, that was a ride, right? From flame tests thatd make you sweat to hoses lighter than your morning coffee mug, we covered the gamut on PTFE hose requirements in aerospace. If this sparked some ideas—or youve got a spec sheet burning a hole in your inbox—lets chat. Drop a line to Эллисон.Йе@teflonx.com, or swing by our контактная страница for a no-BS quote. Were here to make your sourcing smoother than a crosswind landing. Whats your biggest headache right now? Fuel lines? Hydraulics? Hit us up, and lets sort it.

Гофрированный топливный шланг из ПТФЭ для аэрокосмической отрасли

Гофрированный топливный шланг из ПТФЭ обеспечивает надежную подачу топлива в аэрокосмических системах. Конструкция тефлонового топливного шланга выдерживает экстремальные температуры (от -80°C до +250°C) и едкое топливо. Гибкая гофрированная топливная трубка, армированная нержавеющей сталью, минимизирует вибрацию и обеспечивает долговечность в условиях высокого давления. Идеально подходит для систем точного впрыска топлива с низкими затратами на техническое обслуживание.

FAQ: Quick Hits on PTFE Hose Requirements in Aerospace

Whats the deal with AS1055 standards, and do all fire retardant hoses need em?

AS1055 is basically the fire endurance bible for aerospace hoses—tests em at 1100°C to see if they hold for 5 or 15 minutes. Not every hose needs it, but if its near engines or fire zones, yeah, its a must for compliance. Skimp here, and youre inviting FAA headaches.

How lightweight are PTFE hoses compared to metal alternatives?

PTFE can shave off 50-60% weight versus stainless steel lines, per SAE benchmarks. For a 10-meter run, thats like ditching a toolbox from your payload. Perfect for drones or efficiency hawks in commercial fleets.

Can I get custom PTFE hoses that meet multiple AS specs?

Absolutely—thats our bread and butter at Teflon X. We mix AS1055 fire resistance with AS620 performance, tailored to your pressures and routings. Just share the deets, and well mock up options fast.