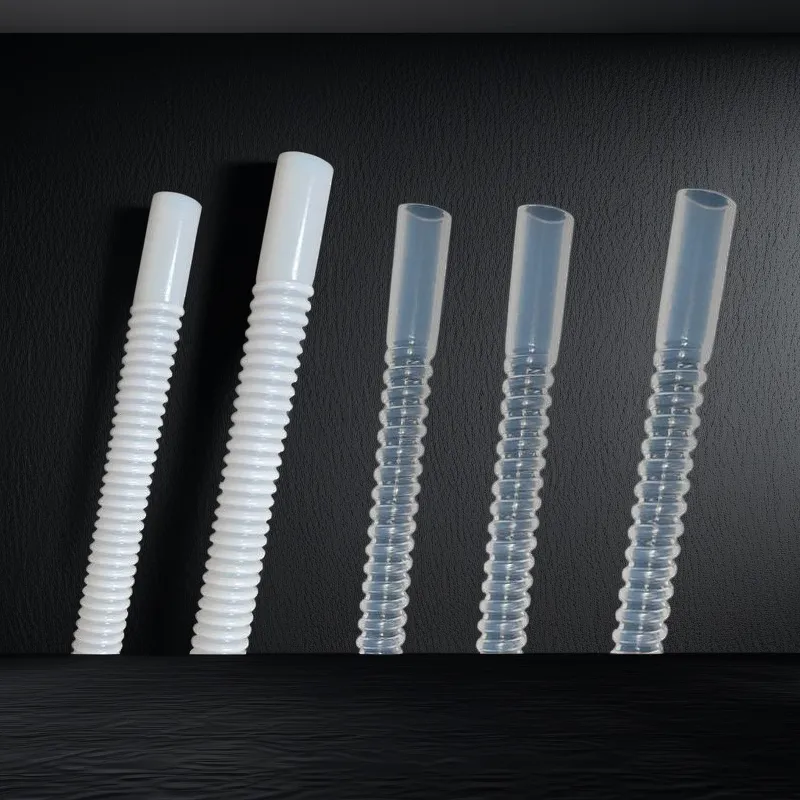

Advanced Corrugated Fuel Tube for Industrial Machinery and Heavy Equipment

In the relentless environment of industrial manufacturing and heavy machinery, component failure translates directly to lost revenue. At Тефлон X, we understand that the lifelines of your machinery—the hoses transferring fuel, oil, and hydraulic fluids—must be virtually indestructible. Our Гофрированная топливная трубка для промышленного оборудования is engineered to meet these exacting standards, combining superior flexibility with advanced protection against environmental hazards.

This product represents the pinnacle of fluid transfer technology, utilizing a high-grade гофрированный топливный шланг из ПТФЭ core that solves the common problems associated with rigid piping and standard rubber hoses. Whether you are operating large-scale diesel generators, injection molding machines, or robotic assembly lines, our solutions ensure uninterrupted operation.

Solving Misalignment and Vibration Issues

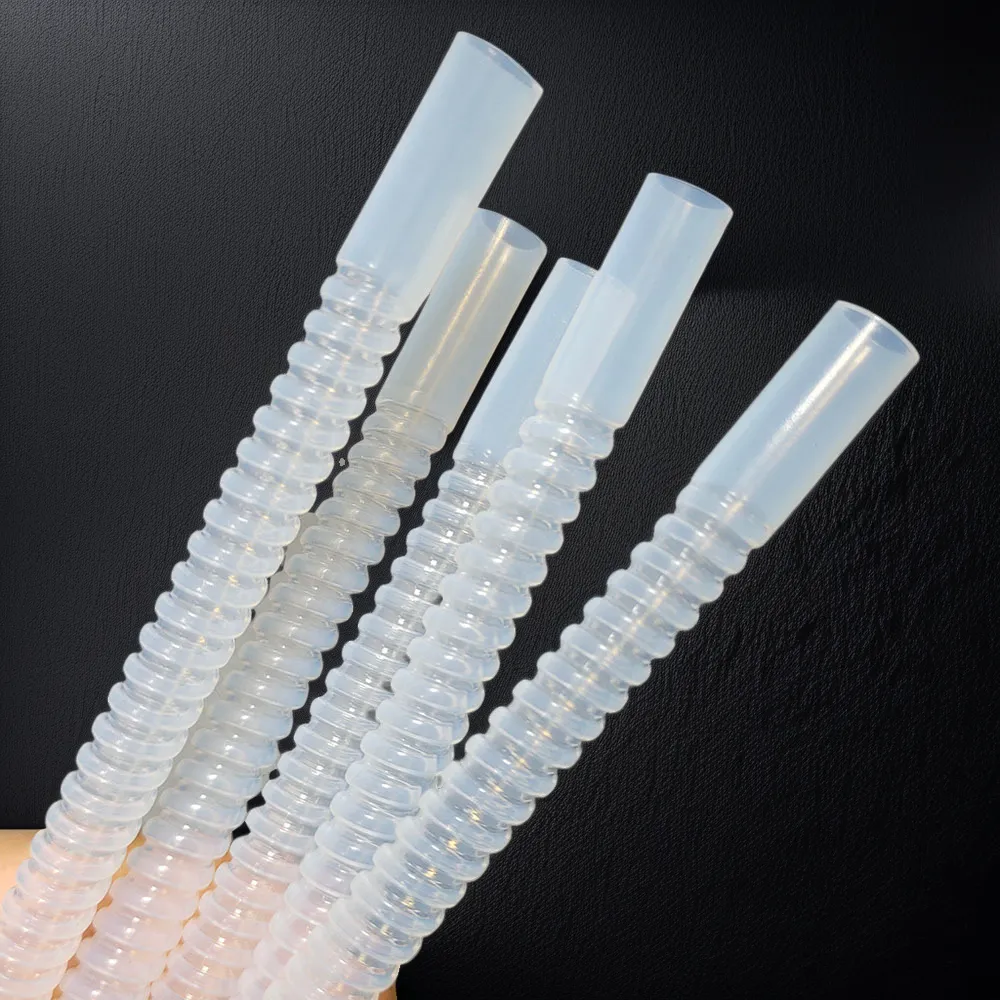

One of the primary causes of leakages in industrial machinery is the vibration and movement inherent in engine operation. Rigid pipes often crack under this stress, and rubber hoses can fatigue over time. The гофрированная топливная трубка design by Teflon X is the ultimate solution. The helical convolutions of the inner tube provide exceptional flexibility, acting as a dynamic expansion joint.

This design effectively compensates for misalignments between connection points and absorbs the high-frequency vibrations generated by industrial engines. By installing our топливная линия из ПТФЭ, you are essentially isolating your fuel systems from mechanical stress, drastically reducing the risk of fatigue-related failures.

EMI Shielding and Thermal Stability

Modern industrial machinery is increasingly reliant on sophisticated electronics. A unique feature of our тефлоновый топливный шланг is its capability for EMI (Electromagnetic Interference) shielding. When fuel or hydraulic fluid flows at high velocities, it can generate static electricity. Our hoses are available with a conductive (carbon-impregnated) inner liner.

When combined with our high-tensile stainless steel braiding, this creates a conductive path that safely dissipates static charge to the chassis ground, preventing static arcing that could damage sensitive electronic control units (ECUs) or sensors. Furthermore, the гофрированный топливный шланг из ПТФЭ offers unmatched thermal stability, maintaining structural integrity in ambient temperatures ranging from -70°C up to +260°C, making it ideal for machinery operating in foundries or near furnaces.

Chemical Resistance and Maintenance

Industrial environments are often contaminated with aggressive chemicals. The топливная линия из ПТФЭ core is chemically inert, meaning it is impervious to fuels, synthetic oils, solvents, and cleaning agents. Unlike rubber, which can swell or degrade when exposed to modern fuel additives, our тефлоновый топливный шланг maintains its shape and flow characteristics indefinitely.

This durability translates to low maintenance. The “fit and forget” nature of a PTFE гофрированная топливная трубка means extended service intervals, fewer replacement parts in your inventory, and a significant reduction in total cost of ownership over the machine’s lifespan.

Основные характеристики и преимущества

- Extreme Flexibility: The self-draining гофрированная топливная трубка design allows for tight routing around complex machinery components without kinking.

- EMI & Static Protection: Optional conductive liners prevent static buildup, protecting both the fuel system and onboard electronics.

- High Pressure Ratings: Reinforced with SS304 or SS316 stainless steel braid to handle high-pressure fuel injection and hydraulic pulses.

- Universal Compatibility: Safe for use with diesel, biodiesel, gasoline, ethanol, methanol, hydraulic oils, and coolants.

- Aging Resistance: PTFE does not age, crack, or harden due to UV exposure or ozone, ensuring a long service life even in outdoor equipment.

Технические характеристики

Тефлон X manufactures hoses to meet strict industrial standards. Below are the typical specifications for our industrial machinery series. We can also custom-fabricate assemblies to your exact length and fitting requirements.

| Технические характеристики | Details |

|---|---|

| Inner Core | Helical Convoluted Virgin or Conductive PTFE |

| Outer Braid | Stainless Steel Wire (AISI 304 Standard, 316 Optional) |

| Диапазон температур | -70°C to +260°C (-94°F to +500°F) |

| Рабочее давление | Up to 180 Bar (depending on diameter) |

| Safety Factor | 4:1 (Burst Pressure is 4x Working Pressure) |

| Available Sizes (ID) | 1/4″ (DN6) to 4″ (DN100) |

| Common Fittings | JIC 37°, BSPP, NPT, Metric, or Flanges |

Common Industrial Applications

Наш гофрированный топливный шланг из ПТФЭ is the preferred choice for engineers designing and maintaining:

- Power Generation Sets (Gensets)

- Construction and Earthmoving Equipment

- CNC Machining Centers

- Plastic Injection Molding Machines

- Marine Propulsion Systems

Partner with Teflon X

Ensure the longevity and reliability of your industrial assets with Тефлон X. Our engineering team is ready to assist you in selecting the perfect тефлоновый топливный шланг configuration for your specific machinery requirements.

For detailed product catalogs and company information, please visit our main website at teflonx.com. To discuss a custom order or request a quotation, please navigate to our Контактная страница или напишите нам напрямую по адресу allison.ye@teflonx.com.

Отзывы

Отзывов пока нет.