Обзор продукта

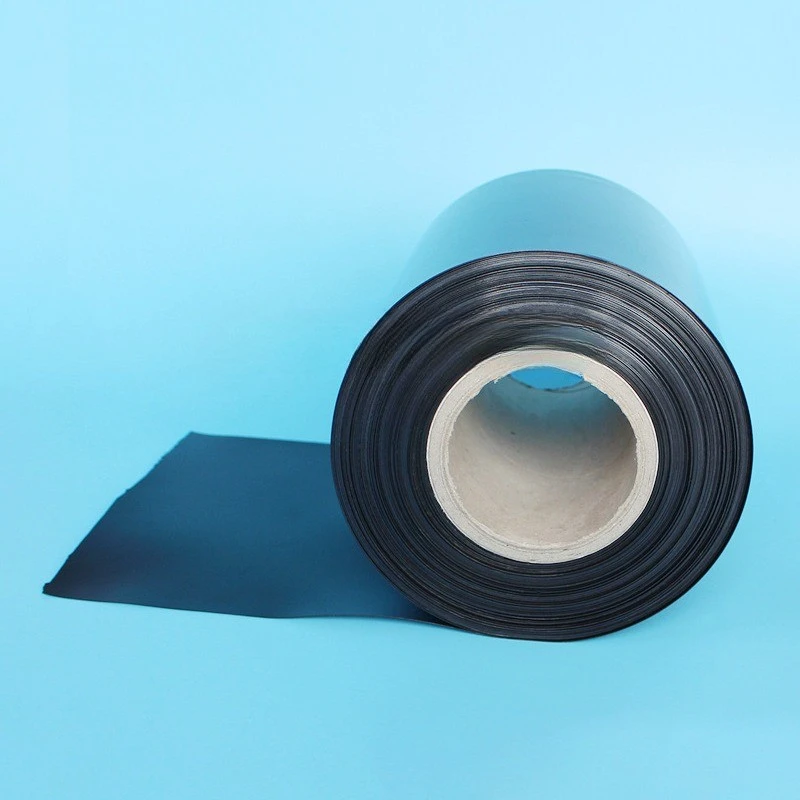

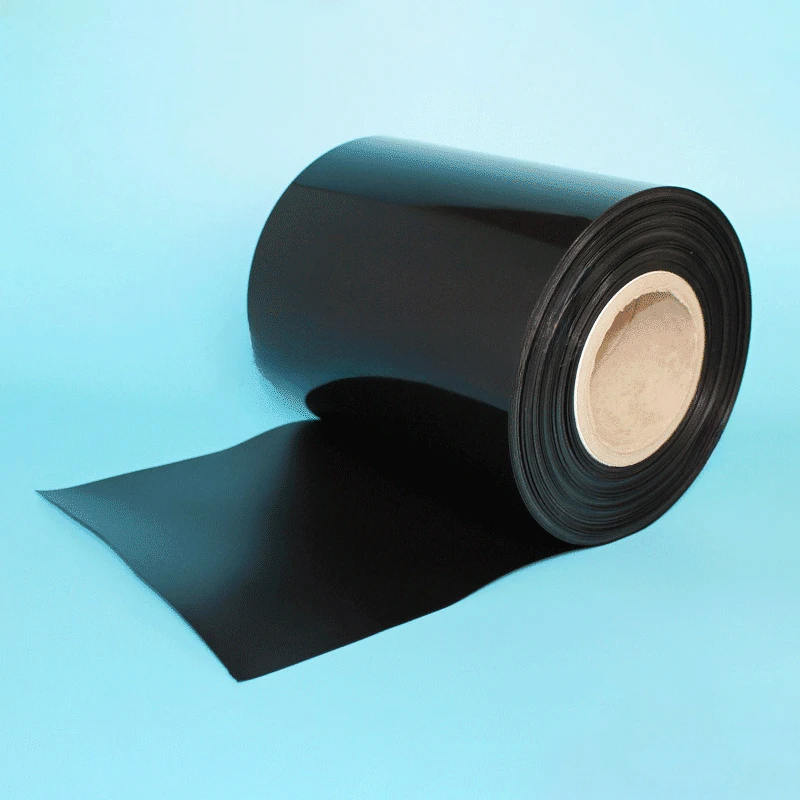

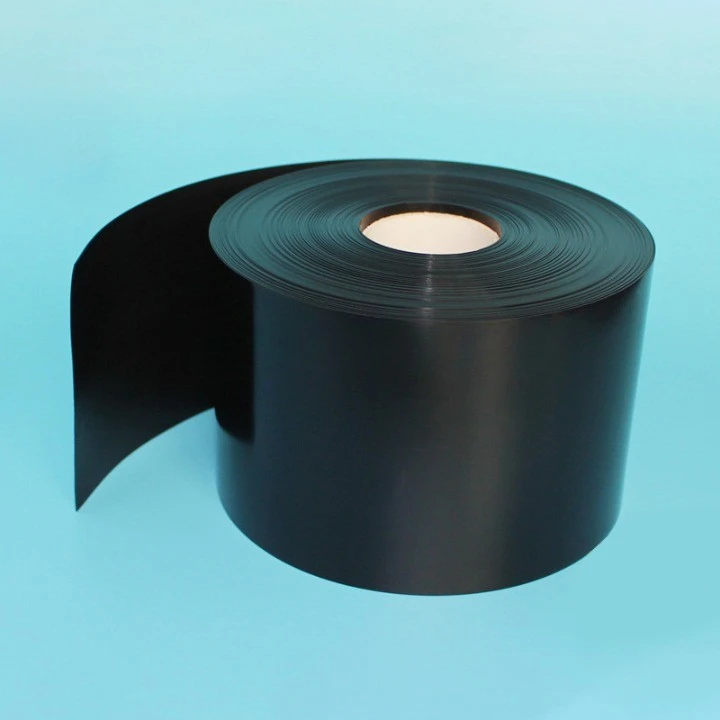

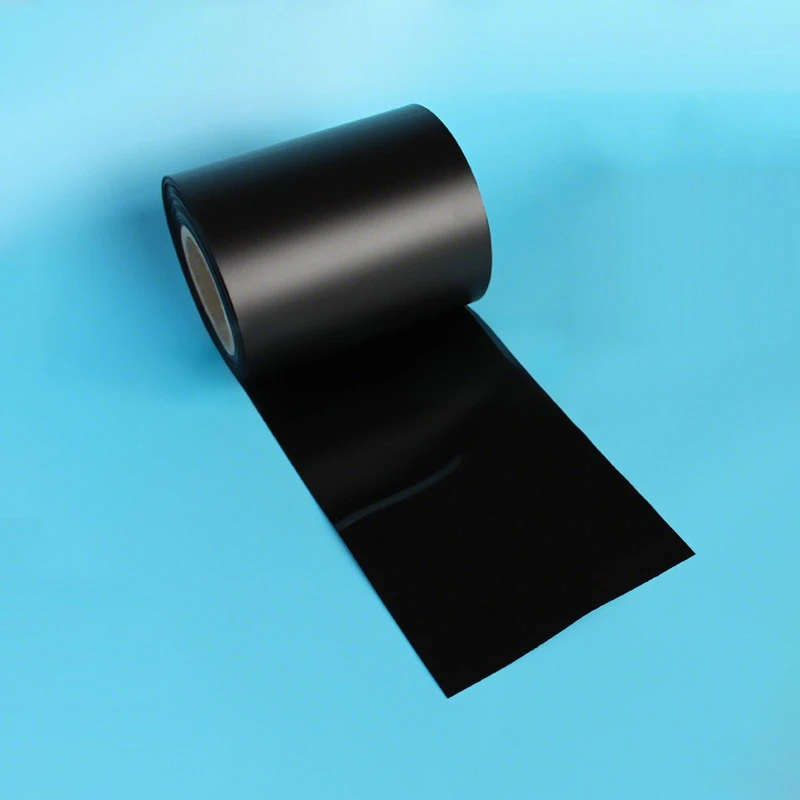

Transform your operations with Teflon X’s UPE Anti-Stick Film, an elite Ultra-High Molecular Weight Polyethylene (UHMWPE) innovation designed to minimize material adhesion and maximize efficiency in the most demanding industrial and medical settings. This high-performance UPE Anti-Stick Film features advanced self-lubrication properties and 8× higher wear resistance than steel, drastically reducing maintenance costs and extending equipment lifespan. As a biocompatible, non-toxic solution, our UPE Anti-Stick Film is FDA and USDA approved, making it perfect for food processing, sterile medical environments, and protective coatings where contamination prevention is critical.

With its ultra-low friction coefficient (0.05–0.15) and slippery, non-adhesive surface, Teflon X’s UPE Anti-Stick Film prevents sticking, buildup, and squeaks in high-contact applications, ensuring smooth material flow and effortless release. Chemically inert to acids, alkalis, solvents, and moisture, this durable UPE Anti-Stick Film thrives in harsh conditions from -200°C to +80°C, offering unmatched impact strength and abrasion resistance. Ideal for conveyor systems, hopper linings, and biomedical coatings, our UPE Anti-Stick Film combines lightweight versatility (density 0.93 g/cm³) with molecular weights over 3,000,000 g/mol for superior performance. Unlock cost savings and reliability—explore more at teflonx.com.

Основные характеристики и преимущества

Тефлоновые X-ы UPE Anti-Stick Film is precision-engineered from premium UHMWPE, delivering these standout attributes for anti-stick excellence in industrial and medical applications:

- Anti-Stick Surface: Exceptionally low surface energy eliminates adhesion of materials, residues, and contaminants, simplifying cleaning and preventing blockages in processing lines.

- Self-Lubricating Performance: Inherent low friction reduces wear, noise, and energy use, eliminating the need for additional lubricants in sliding mechanisms and guides.

- 8× Wear Resistance Over Steel: Superior abrasion resistance outperforms steel, extending durability in high-impact zones like chutes, hoppers, and conveyor components.

- Biocompatibility and Compliance: FDA/USDA-approved, non-toxic, and hypoallergenic, ensuring safe contact in food processing, medical devices, and sterile packaging.

- High Impact Strength: No-break toughness absorbs shocks and vibrations, protecting against damage in dynamic industrial and medical handling scenarios.

- Chemical and Corrosion Resistance: Inert to harsh chemicals, solvents, and moisture (<0.01% absorption), maintaining integrity in corrosive environments without degradation.

- Thermal Versatility: Flexible from cryogenic lows (-200°C) to +80°C, with low thermal expansion for reliable performance in temperature-fluctuating applications.

- Lightweight and Customizable: Low density for easy installation, available in films, tapes, or sheets for tailored UPE Anti-Stick Film solutions in protective coatings.

This robust UPE Anti-Stick Film sets a new standard for non-stick reliability, slashing downtime and costs while enhancing hygiene and efficiency across sectors.

Приложения

Тефлоновые X-ы UPE Anti-Stick Film excels in anti-adhesion roles, powering seamless performance in industrial machinery, food handling, and medical innovations:

- Industrial Conveyor Systems: Linings for belts, rollers, and guides to ensure smooth material flow, reduce friction, and prevent sticking in manufacturing and logistics.

- Food Processing Equipment: Hopper and chute coatings to minimize residue buildup, facilitating hygienic, easy-release operations compliant with FDA standards.

- Medical and Biomedical Devices: Protective films for implants, prosthetics, and sterile packaging, leveraging biocompatibility to avoid contamination and ensure safe contact.

- Protective Coatings: Anti-wear overlays for machinery guards, slides, and tank liners, combating abrasion and corrosion in chemical and bulk handling processes.

- Automotive and Aerospace: Vibration-dampening tapes for assemblies and joints, reducing squeaks, rattles, and friction in high-movement components.

- General Material Handling: Wear strips in packaging lines and transport systems, promoting efficient, low-maintenance flow of powders, granules, and sticky substances.

From food-safe processing to precision medical uses, our UPE Anti-Stick Film delivers proven anti-stick and durability advantages.

Технические характеристики

Below is a comprehensive table of standard parameters for Teflon X’s UPE Anti-Stick Film. Custom configurations, including adhesive-backed variants or specific thicknesses, are available—contact us for personalized UPE Anti-Stick Film options.

| Свойство | Value/Range | Test Standard/Notes |

|---|---|---|

| Material Type | Ultra-High Molecular Weight Polyethylene (UHMWPE) | ASTM D4020 |

| Molecular Weight | >3,000,000 g/mol | Gel Permeation Chromatography |

| Плотность | 0.93 g/cm³ | ASTM D792 |

| Tensile Yield Strength | 19.3–23 MPa | ASTM D638 |

| Elongation at Break | >300% | ASTM D638 |

| Shore D Hardness | 60–65 | ASTM D2240 |

| Impact Strength (Izod) | No Break (Unnotched) | Highest among thermoplastics |

| Коэффициент трения | 0.05–0.15 (Dynamic) | Comparable to PTFE |

| Износостойкость | 8x Carbon Steel | Taber Abrasion Test |

| Operating Temperature | -200°C to +80°C | Continuous Use |

| Химическая стойкость | Excellent (Acids, Alkalis, Solvents) | Except Oxidizing Acids |

| Поглощение воды | <0.01% (24 hrs) | ASTM D570 |

| Толщина | 0.025–1.5 mm | Customizable, Skived Film |

| Ширина | Up to 2 m | Roll or Sheet Format |

| Соответствие требованиям FDA | Yes (Non-Toxic, Food Contact Safe) | 21 CFR 177.1520 |

| Porosity (Microporous) | 30–70% (Optional) | For Filtration Grades |

Note: Values are typical and may vary based on processing and grade. For detailed datasheets, visit teflonx.com.

Почему стоит выбрать Teflon X?

Teflon X drives polymer excellence, producing our UPE Anti-Stick Film with state-of-the-art testing for anti-stick superiority and biocompatibility that exceeds expectations. This high-performance UPE Anti-Stick Film integrates effortlessly, cutting maintenance by up to 50% through self-lubrication and wear resistance, while upholding the strictest hygiene standards. With our global reach, customization expertise, and dedicated support, Teflon X is your go-to for innovative UPE Anti-Stick Film that boosts productivity and safety.

Experience the difference with Teflon X’s versatile UPE Anti-Stick Film—check out our full lineup at teflonx.com or connect via our Свяжитесь с нами страница. For prompt guidance, email Эллисон.Йе@teflonx.com.

Отзывы

Отзывов пока нет.