So, you’re staring at a blueprint for a new 6-axis robotic arm, and the sensor housing requirements are looking… messy. You need something that doesn’t mess with RF signals, can handle high temps, and has a friction coefficient practically nonexistent. Naturally, you pick Polytetrafluoroethylene.

But here’s the thing nobody tells you in university: Machining PTFE Rods into complex geometries is like trying to machine a block of solidified marshmallows. It squishes, it creeps, and if you look at it wrong, the tolerance goes out the window.

I’ve spent years shouting at CNC machines trying to get this material to behave. At Teflon X, we’ve figured out the secret sauce. Today, I’m ditching the textbook theory and talking about how we actually cut this stuff for high-end robotics sensors without tearing our hair out.

Why Robotics Engineers Are Obsessed with PTFE (And Why Machinists Hate It)

If you are a mechanical engineer, you know why you want it. It’s the Dielectric Constant (Dk).

For sensitive robotics sensors—especially capacitive sensors or high-frequency radar modules used in autonomous navigation—housing materials matter. Standard metals block signals. Nylon sucks up moisture like a sponge, which changes its dielectric properties based on humidity.

PTFE? It sits pretty with a Dk of around 2.1 and a Dissipation Factor (Df) of 0.0002. It’s invisible to the sensor.

But for the guy running the lathe, it’s a nightmare. It has a high coefficient of thermal expansion (about 135 x 10^-6 K^-1). You machine it warm, it measures perfect. You take it off the machine, it cools down, and suddenly your precision bore is undersized.

The Setup: Don’t Crush the Material

The number one mistake I see when shops try machining PTFE for the first time? They treat it like aluminum.

If you clamp a PTFE rod in a standard 3-jaw chuck with normal hydraulic pressure, you’ve already failed. The material compresses. You bore the center out perfectly round. Then, when you release the chuck pressure, the material springs back to its original shape. The result? A tri-oval bore that is absolutely useless for a precision sensor fit.

The Fix: Collets and Soft Jaws

We always use collets for smaller diameter PTFE-Stäbe or pie-jaws (full grip jaws) for larger diameters. You want to wrap the part in love, not strangle it.

- Pressure Rule: Turn the hydraulic pressure down. Way down. If you think it’s too loose, it’s probably almost right.

- Unterstützung: If you are hanging the rod out more than 3x its diameter, use a live center. But be careful—a sharp live center point can split PTFE like a log. We use a custom blunt-nose center or a cap to distribute that force.

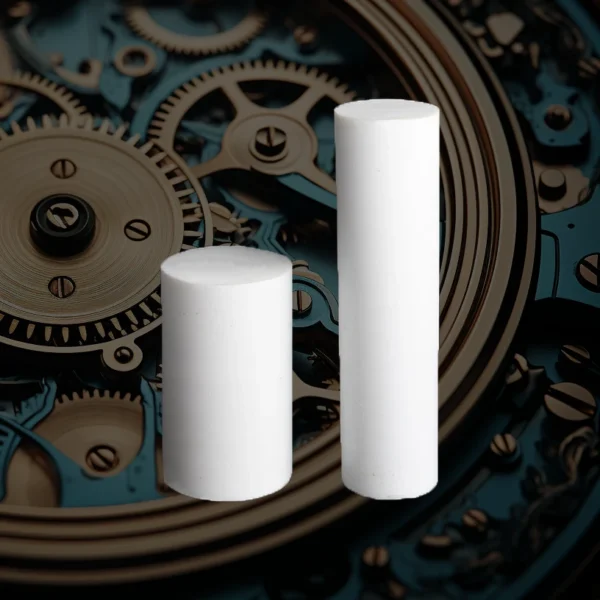

Teflon-Rundstab – PTFE-Stangen für die chemische Industrie

Teflon-Rundstäbe oder PTFE-Stäbe sind für die Anforderungen der chemischen Industrie konzipiert und zeichnen sich durch hervorragende Säurebeständigkeit aus. Ihre Korrosionsbeständigkeit macht sie ideal für Geräte und Auskleidungen. Passen Sie sie an Ihr Projekt an.

Tooling: Carbide vs. HSS (The Debate)

Okay, this might be controversial. Some old-school guys swear by High-Speed Steel (HSS) because you can grind it to a razor edge. And they aren’t entirely wrong. PTFE needs a sharp tool. Not “kinda sharp.” I mean scalpel sharp.

However, for production runs like custom sensor housing parts, HSS wears out faster than you’d think, not from abrasion, but heat build-up affects the edge retention over thousands of cycles.

I prefer polished, up-sharp carbide inserts meant for aluminum (uncoated). The coatings on general-purpose inserts (like TiAlN) actually round the cutting edge slightly. That microscopic dullness causes the PTFE to compress rather than shear. Compression = heat = bad tolerances.

Speeds and Feeds: The Math Behind the Madness

You can run PTFE fast. Really fast. But chip evacuation is your enemy. Unlike metal chips that break, PTFE produces a continuous, stringy ribbon that wants to wrap around your tool, your part, and the chuck. It’s a “bird’s nest” disaster waiting to happen.

Here is the general rule of thumb we use at Teflon X für CNC turning PTFE:

Cutting Speed (Vc):

You can push this up to 600-800 m/min if your machine can handle it and the balance is good.

Feed Rate (fn):

Keep it relatively high—0.15 to 0.3 mm/rev. Why? If you feed too slow, you dwell. Dwelling creates friction. Friction creates heat. Heat changes your dimensions.

The Formulas (Simplified for the Shop Floor)

Since we are talking shop, let’s look at the actual calculations.

RPM Calculation:

RPM = (Vc x 1000) / (3.14 x D)

- Vc = Surface Speed (m/min)

- D = Diameter of the stock (mm)

Chip Load per Tooth (for milling sensor pockets):

fz = Vf / (n x z)

- Vf = Table feed (mm/min)

- n = RPM

- z = Number of flutes

Profi-Tipp: For milling sensor housings, stick to single-flute or 2-flute end mills. More flutes just leave less room for those fluffy chips to escape.

Managing the “Fuzz”: Deburring PTFE

This is the part that drives everyone crazy. You machine the part, it looks great, but under a microscope, the edges look like a fuzzy sweater. Burrs on PTFE don’t break off; they just fold over.

For robotics sensors, loose burrs are a disaster. If a piece of PTFE fluff gets into the optical path or the capacitive gap, the sensor readings go haywire.

We don’t use files. We don’t use tumbling (usually).

We use air-chilled knives or cryogenic deburring if the batch is huge. For smaller runs, it’s manual trimming with a brand new X-Acto blade under magnification. Yeah, it’s slow. But quality control is everything.

Kundenspezifischer PTFE-Stab für Öl und Gas – Hochleistungsschmierstange

PTFE-Stäbe sind für Öl- und Gasanwendungen konzipiert und bieten hohe Schmierfähigkeit und Temperaturbeständigkeit. Diese maßgeschneiderten Teflon-Rundstäbe verbessern die Effizienz in petrochemischen Anlagen. Maßgeschneidert nach Ihren Vorgaben.

Case Study: The Lidar Housing Project

Let me share a quick story (names changed to protect the NDA, obviously).

A robotics startup in Boston contacted us. They needed a protective housing for a spinning Lidar unit on a warehouse bot. They tried machining it from Acetal (Delrin) first.

The problem? Acetal is great, but it has a higher dielectric constant than PTFE. It was creating “ghost” data in their point cloud.

They switched to Teflon X PTFE.

Their local machine shop tried to make the parts. They came back oval-shaped and with surface finishes that looked like a vinyl record. The roughness was scattering the Lidar beam.

Our Approach:

- Material: Used stress-relieved Virgin PTFE Rods. (Stress relieving is crucial—bake it, let it cool slowly, then machine).

- Roughing: We roughed the material to within 1mm of the final size.

- Resting: We took the parts out of the machine and let them sit overnight. PTFE relaxes after you cut the skin off.

- Finishing: Re-chucked with soft jaws (bored to the exact rough diameter) and did a final skim cut at high speed with a high-positive rake insert.

The Result: Surface finish of Ra 0.4 µm and roundness within 0.02mm. The sensor data cleaned up instantly.

Comparing Materials for Sensor Housings

I made this chart so you can see why machining PTFE is worth the headache compared to easier plastics.

| Besonderheit | PTFE (Teflon) | Nylon 6/6 | Acetal (Delrin) |

|---|---|---|---|

| Bearbeitbarkeit | Moderate (Squishy) | Gut | Exzellent |

| Dielectric Constant (1MHz) | ~2.1 | ~3.6 | ~3.7 |

| Water Absorption (24h) | < 0.01% | ~1.5% | ~0.25% |

| Friction Coeff. | 0.05-0.10 | 0.28 | 0.35 |

| Heat Resistance | Up to 260°C | ~100°C | ~85°C |

You see the water absorption on Nylon? 1.5%. In a humid warehouse, your sensor housing literally changes size and electrical properties. PTFE doesn’t care if it’s underwater or in a desert.

Designing for Manufacturability (DFM) with PTFE

If you are the engineer drawing this up, help us help you.

- Avoid Thin Walls: If you design a wall thickness of 0.5mm on a 50mm diameter part, it will distort. Try to keep walls above 1.5mm if possible.

- Radii are your friends: Sharp internal corners create stress risers. In PTFE, stress moves. A radius helps the material flow rather than tear.

- Tolerances: Don’t put +/- 0.01mm on everything unless you absolutely need it. It drives the cost up because we have to machine it, measure it, cool it, measure it again, and maybe cut it again.

Why Sourcing the Right Rod Matters

Garbage in, garbage out. A lot of cheap PTFE rods on the market are full of reprocessed material (regrind). Recycled PTFE has inconsistent density. You hit a hard spot or a void in the middle of a cut, and your tool chatters.

Bei Teflon X, we ensure our stock is consistent. When you are doing CNC turning PTFE, consistency is the only thing saving you from constant offsets. Check out our inventory here: PTFE Rods Product Category. We keep the good stuff in stock.

Final Thoughts: It’s an Art

Machining this material isn’t just punching codes into a Fanuc controller. It’s about feel. It’s about knowing that the material is going to grow when it gets hot and shrinking when it hits the AC air.

If you are struggling with a complex sensor housing, or your current supplier keeps sending you oval parts, maybe it’s time to talk to people who actually enjoy the challenge.

We handle the weird stuff. The complex geometries. The tight tolerance robotics parts.

Ready to get your parts made right?

Drop us a line.

- Email me directly: Allison.Ye@teflonx.com

- Angebot anfordern: Kontaktieren Sie uns

PTFE-Rundstab mit Korrosionsbeständigkeit – Sondergrößen

PTFE-Rundstäbe bieten unübertroffene Korrosionsbeständigkeit für die chemische und petrochemische Industrie. Dieser Teflonstab überzeugt durch seine anpassbaren Spezifikationen auch unter harten Bedingungen. Die erste Wahl für langlebige Anlagenlösungen.

FAQ: Machining PTFE for Robotics

Q1: Can you hold tight tolerances like +/- 0.001″ on PTFE parts?

A: Yes, but it depends on the geometry. On a solid block? Easy. On a thin-walled sensor ring? It’s harder. We usually suggest holding +/- 0.002″ for thin parts to keep costs reasonable, but if your application demands the “tenth,” we use specific temperature-controlled machining processes to achieve it.

Q2: Why is my PTFE part changing size after I receive it?

A: That’s usually thermal expansion or stress relaxation. PTFE has a “memory.” If it wasn’t stress-relieved before machining, it will try to go back to its original shape over time. Also, if you measure it in a 20°C room and we machined it at 24°C, there will be a measurable difference. We recommend stabilizing the parts at your operating temp before final assembly.

Q3: Do you recommend coolants when machining PTFE?

A: Absolutely. While PTFE is self-lubricating, the coolant isn’t for lubrication—it’s for heat removal. We use water-soluble coolants to keep the part temperature stable. If you dry machine it, the heat builds up, the part expands, you cut it “to size,” and then it shrinks undersize when it cools.

Q4: Is PTFE suitable for vacuum environments in space robotics?

A: Generally, yes. PTFE has low outgassing properties compared to many other plastics, especially if you use high-grade Virgin PTFE. It stands up to the vacuum and radiation well, making it a solid choice for aerospace and space-grade sensor housings.