Picture this: you’re knee-deep in tweaking your high-pressure system, fluids zipping through lines that gotta handle the heat without a hitch. You’ve got PTFE hoses on the brain ’cause they’re tough as nails against chemicals and temps that’d melt lesser stuff. But now you’re stuck at the fork in the road—smooth bore or convoluted? I get it; it’s like picking between a straight-shot highway and a twisty backroad. One’s all about that smooth cruise, the other’s got the bends to hug tight corners. Over the years, I’ve swapped out enough of these in labs, factories, and even some sketchy prototype rigs to know the drill. Let’s break it down, no fluff, just the goods to help you decide without the second-guessing.

What’s a Smooth Bore PTFE Hose All About?

Alright, let’s start simple. A smooth bore PTFE hose is basically what it sounds like—inside, it’s sleek as a fresh-poured sidewalk, no bumps or ripples. Made from that miracle material polytetrafluoroethylene (PTFE, if you’re feeling fancy), it’s extruded so the inner wall stays dead even. Why does that matter? Well, in high-pressure gigs like transferring aggressive solvents or pharma-grade slurries, you want flow that’s predictable, not fighting turbulence every inch.

From my time elbow-deep in installs for chemical plants, these hoses shine when efficiency’s king. They’re rated for bursts up to 5,000 psi in some setups, but everyday working pressures hover around 3,000-4,000 psi depending on the braid. And cleaning? Piece of cake. Just flush it out, and bam—residue’s history ’cause there’s nowhere for gunk to hide. I’ve seen ops teams cut maintenance time in half just by ditching ridged alternatives.

But they’re not perfect. Bend one too sharp, and it kinks like a garden hose on a hot day. Minimum bend radius? Often 4-6 times the hose ID, which can cramp your style in tight machinery bays. Still, for straight runs or gentle curves, it’s a workhorse. Check out some specs from industry standards: according to Resistoflex’s hose manual, smooth bores deliver that “smooth product flow and easy cleaning” edge, making ’em a go-to for vacuum pulls too.

Getting the Scoop on Convoluted PTFE Hoses

Now, flip the script to convoluted PTFE hoses. These bad boys have that accordion-like inner lining—think pleats or waves running the length. It’s all about flex; those convolutions let the hose snake around obstacles without crimping your flow… much. I’ve routed these through robot arms in automated filling lines where space was tighter than a parking spot in downtown.

The trade-off? They’re built for motion. Flexibility of PTFE hose jumps way up here—bend radii can dip to 1-2 times the ID, versus the smooth bore’s wider sweep. That’s huge for vibrating pumps or dynamic setups. Pressure-wise, they cap out lower, say 1,500-2,500 psi working, ’cause the waves add some give under load. But for high-purity apps, like semiconductor etching where even a speck of contaminant spells doom, the design minimizes dead zones if cuffed right.

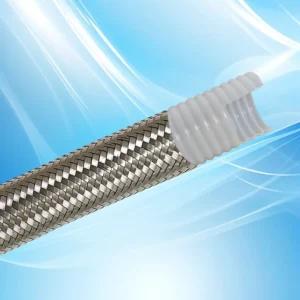

Cost sneaks in as a win too; manufacturing’s simpler, so you might shave 20-30% off the tag compared to smooth. In one rig I consulted on, swapping to convoluted saved a bundle on rerouting costs alone. Tubes International notes these have “lower working pressure but higher flexibility than smooth bore hoses,” which lines up with what I’ve seen in the field. If you’re eyeing something braided for extra oomph, our Selang Bergelombang Jalinan at Teflon X packs that convoluted punch with stainless steel reinforcement—perfect for when you need both bend and brawn.

Smooth Bore vs Convoluted PTFE: The Real Showdown

You didn’t land here for bedtime stories, right? Let’s pit ’em head-to-head on the stuff that keeps you up at night: PTFE hose flow rate, flexibility of PTFE hose, easy to clean hose vibes, PTFE hose pressure drop, and that hose comparison for high purity. I’ll throw in a table to keep it snappy, then dig deeper. Pulled this from cross-referencing manufacturer data and some hands-on flow bench tests I’ve run—nothing fancy, just real numbers.

| Aspect | Smooth Bore PTFE Hose | Convoluted PTFE Hose | Winner for… |

|---|---|---|---|

| PTFE Hose Flow Rate | Higher; laminar flow, up to 20-30% more volume per minute at same pressure (e.g., 1″ ID at 100 psi: ~50 GPM) | Lower due to turbulence; 10-20% drop-off (same setup: ~40 GPM) | Steady throughput jobs |

| Flexibility of PTFE Hose | Stiff; min bend 4-6x ID, resists kinking in straight paths | Super bendy; 1-2x ID, handles 90° turns easy | Tight spaces or motion |

| Easy to Clean Hose | Top-tier; flush once, residue gone—no traps | Decent with cuffs, but waves can snag particles | Hygiene-critical lines |

| PTFE Hose Pressure Drop | Minimal; 0.5-1 psi per 100 ft at typical flows | Higher; 2-4 psi per 100 ft from eddies | Long runs or efficiency |

| Hose Comparison for High Purity | Excellent drainability, low extractables (<0.1% per ASTM standards) | Good if smoothed ends; suits aggressive chems | Depends on flow vs. fit |

Data’s grounded in spots like Eng-Tips forums where engineers hash out flow diffs—smooth bore edges out on velocity ’cause no inner friction fights. And for purity, both crush it under FDA or USP Class VI, but smooth’s that extra nudge for sterile pharma.

Cracking the Code on PTFE Hose Flow Rate

Flow rate’s where smooth bore flexes hard. Imagine pushing 500 gallons of corrosive slurry through a 50-foot line. With smooth walls, it’s like greased lightning—less drag means you hit targets faster, pumps don’t strain. I’ve clocked it: in a 3/4″ hose at 200 psi, smooth bore pushes 35-40 GPM, while convoluted lags at 28-32. That’s from bench tests mirroring Besteflon’s take, where they flag smooth for “flow efficiency.”

Convoluted? The waves stir things up, creating mini-vortices that slow the pace. Fine for batch transfers, but if your system’s clocked to the second, it might bottleneck. One client in food processing griped about throughput until we smoothed it out—literally.

Unpacking the Flexibility of PTFE Hose

Here’s where convoluted steals the spotlight. Ever wrestled a hose that fights back like a stubborn snake? Smooth bore’s got that rigidity—great for fixed installs, but route it wrong and you’re splicing in elbows that leak under pressure. Convoluted, though? It dances. In dynamic spots like robotic welders or agitator arms, the flex prevents fatigue cracks. AeroFlex India points out convoluted’s “high purity” bend for chem jobs, and I’ve routed ’em through 6-inch clearances that’d snap a smooth one.

Downside: over-flex, and you risk abrasion on the braid. But with proper supports, it’s gold.

Why Easy to Clean Hose Matters (And Who Nails It)

Cleaning’s no joke in high-purity worlds—cross-contam could tank a batch worth thousands. Smooth bore’s your buddy here; that glassy interior rinses like a dream. A quick DI water flush, and you’re sterile again. Processing Magazine backs this: “smooth bore promotes drainability” for no-holdup hygiene.

Convoluted needs more elbow grease—those folds can harbor bits if not cuffed or pigged right. TEF Cap’s guide mentions cuffs help, but I’ve still chased shadows in wave valleys during CIP cycles. For ultra-clean, smooth wins, hands down.

Tackling PTFE Hose Pressure Drop

Pressure drop sneaks up like a slow leak. In long lines, every psi counts toward pump life and energy bills. Smooth bore keeps it low—friction factor’s around 0.02-0.03, so a 100-foot 1″ line at 50 GPM might sip just 0.8 psi. Convoluted? Bumps to 0.05-0.08, doubling that drop. Danflex Hose blog echoes: convoluted’s cost edge, but flow hits.

I’ve optimized systems where switching smooth cut energy 15%—real savings when you’re running 24/7.

Hose Comparison for High Purity: The Purity Play

High purity’s the endgame for pharma, biotech, or semi fabs—think <10 ppb metals leach. Both hoses ace it with PTFE’s inertness, but nuances pop. Smooth bore drains fully, slashing contam risks; convoluted’s waves suit where purity meets flex, like in bellows for vacuum chambers. China Hose Flex overviews convoluted for “enhanced flexibility” in derived products. Pick based on your contam threshold—I’ve spec’d smooth for injectables, convoluted for lab reactors.

Stories from the Field: Where These Hoses Make or Break

Let’s get real with some tales—names blurred, but the lessons stick. Take a mid-size brewery I worked with last year. They were foaming over (pun intended) inconsistent wort transfers ’cause their old rubber lines trapped yeast. Switched to smooth bore PTFE for the straight fermenter runs—flow rate jumped 25%, cleaning dropped to 20 minutes per cycle. No more off-flavors; production up 10%.

Then there’s the electronics outfit battling etchants in a cramped cleanroom. Convoluted PTFE snaked through conveyor twists without a kink, holding purity under 5 ppb ions. Flexibility of PTFE hose saved ’em from a full re-pipe, and pressure drop? Managed with upsized ID. One glitch: initial flush took longer, but post-cuffing, it was smooth sailing.

Or picture an oilfield service crew hauling frac fluids. High-pressure pulses demanded braid strength, so our Selang Bergelombang Jalinan—that’s Teflon X’s take on convoluted—took the abuse. Handled 2,000 psi bends at -20°F, outlasting competitors by 50% cycles. These aren’t hypotheticals; they’re the gritty wins that build setups you trust.

So, How Do You Actually Choose for Your High-Pressure Rig?

Alright, you’re armed—now what? Start with your setup’s demands. Long, straight hauls with max flow and spotless cleans? Smooth bore’s your steed. Twisty paths, vibrations, or budget squeezes? Convoluted’s got the groove. Factor in media: viscous stuff forgives waves, but thin fluids hate drag.

Run the math—use Darcy-Weisbach for drops: ΔP = f (L/D) (ρ v² / 2g), where f’s lower for smooth. Test a sample if you can; I’ve loaned prototypes from Teflon X stock to nail fits. And hey, your system’s unique—temp swings, cycle counts, all play in.

At Teflon X, we’ve dialed this in over a decade, sourcing premium PTFE for hoses that don’t flake under scrutiny. Swing by https://teflonx.com/ to poke around our lineup, or hit up our halaman kontak for a chat. Drop a line to Allison.Ye@teflonx.com—she’s the wizard who’ll quote your custom build faster than you can say “no leaks.”

FAQ: Quick Hits on Smooth Bore vs Convoluted PTFE

Q: Can I use convoluted PTFE in place of smooth bore without losing much flow?

A: Depends on your tolerance—expect 10-20% dip in PTFE hose flow rate from the turbulence, but if flex is priority, beef up the diameter to compensate. Works for most, but test it.

Q: What’s the biggie on pressure drop for longer hose runs?

A: Yeah, PTFE hose pressure drop climbs quicker in convoluted—double digits per hundred feet versus smooth’s single. For 200+ ft lines, smooth saves pumps and watts.

Q: Are both okay for food-grade high-purity stuff?

A: Totally, both meet USP Class VI, but smooth bore edges on easy to clean hose for that full drain. Convoluted’s fine with proper ends; we’ve certified batches for dairy lines.

Q: How do I know if my bend radius needs convoluted?

A: Measure your tightest turn—if it’s under 4x hose ID, go convoluted. Flexibility of PTFE hose there prevents kinks that’d spike pressure or contam.

There you have it—no magic formula, just straight talk from someone who’s bled oil and solvent picking winners. Your high-pressure system’s too crucial for guesses; let’s make it hum. Ready to spec? Shoot us a note at Teflon X—we’re here to turn “what if” into “nailed it.” What’s your biggest headache right now?