Panoramica del prodotto

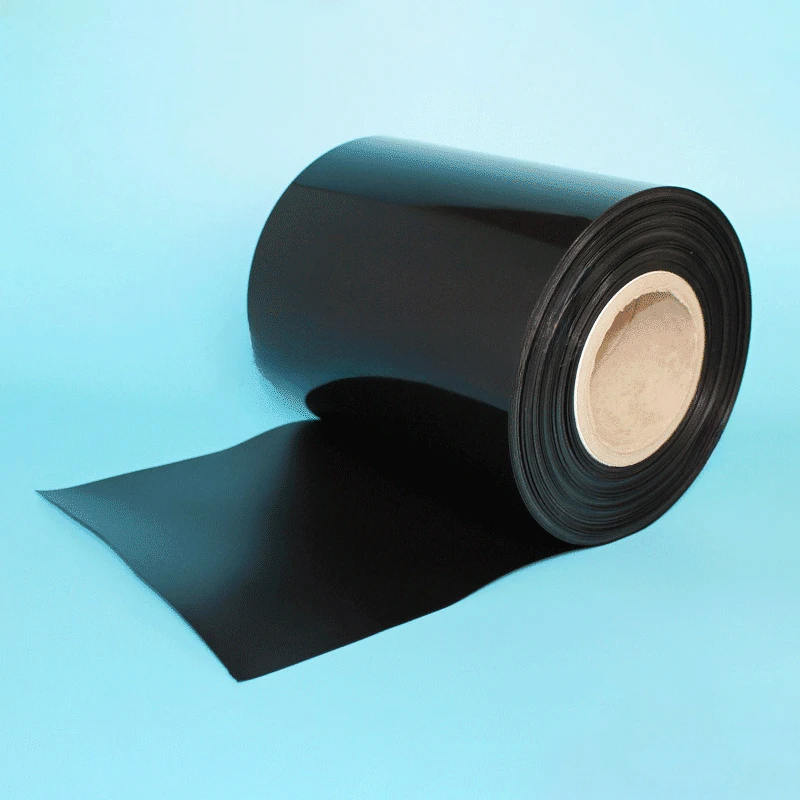

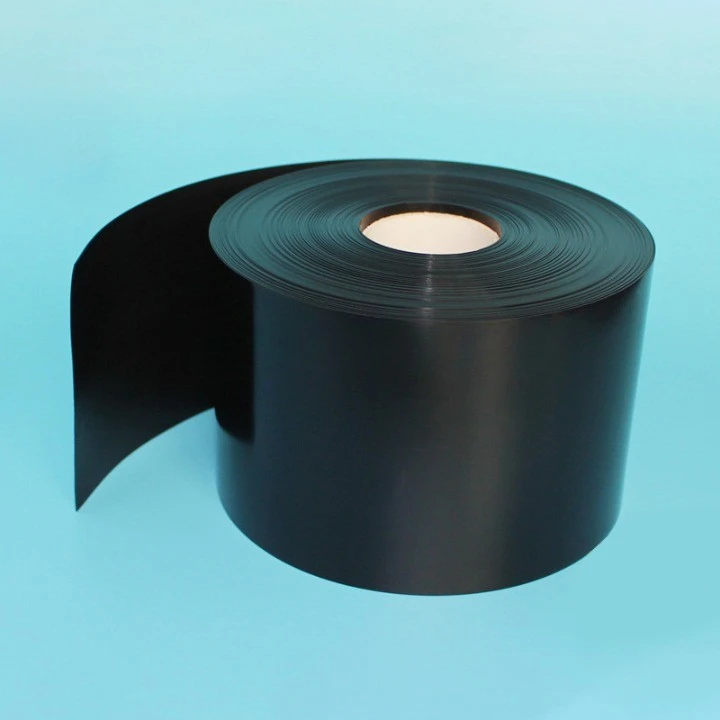

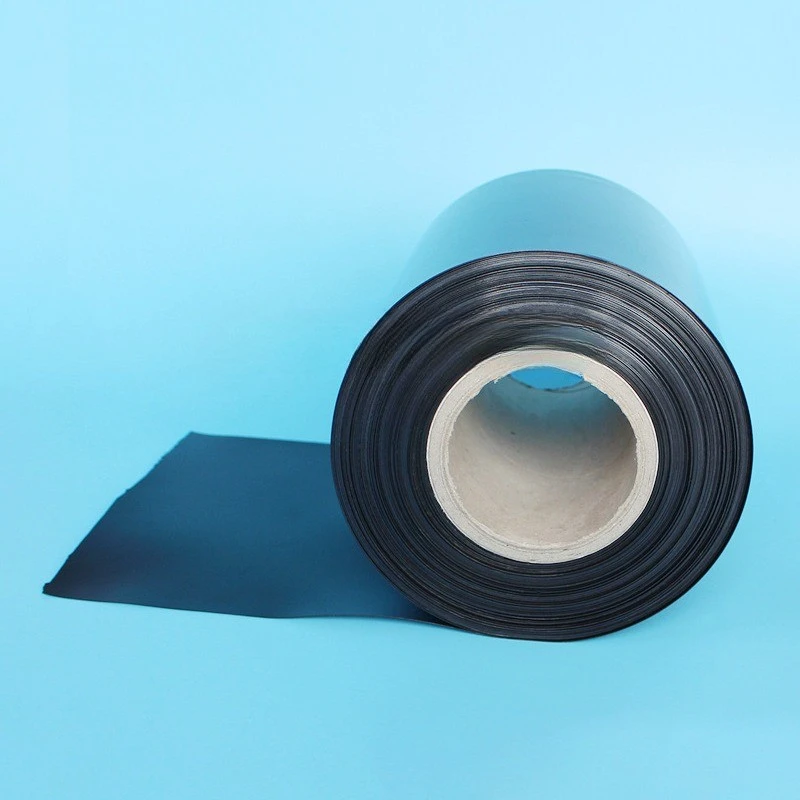

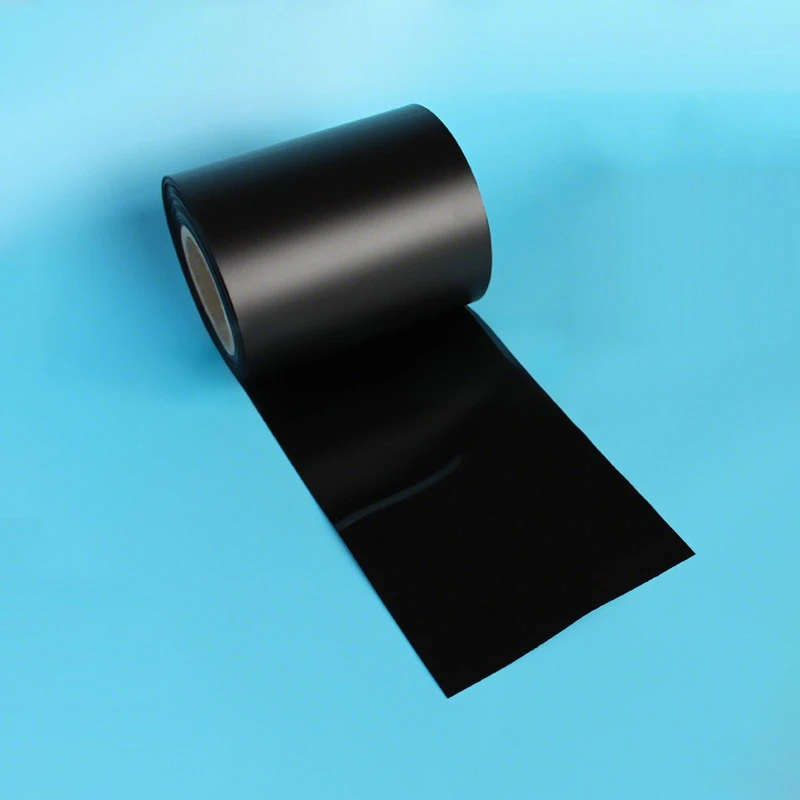

Elevate your industrial solutions with Teflon X’s UHMWPE Polyethylene Film, a premier Ultra-High Molecular Weight Polyethylene (UHMWPE) innovation renowned for its exceptional thermal stability and superior electrical insulation properties. This high-performance UHMWPE Polyethylene Film safeguards machinery and components in demanding environments, offering reliable operation from cryogenic lows (-200°C) to elevated temperatures (+80°C) with minimal thermal expansion, while providing robust dielectric strength (20–30 kV/mm) to prevent electrical breakdowns in power cables and insulating applications. With outstanding wear resistance—up to 15× that of carbon steel—and low-temperature flexibility that maintains ductility without brittleness, our UHMWPE Polyethylene Film extends service life in automotive, textile, and chemical sectors, reducing downtime and maintenance costs.

Teflon X UHMWPE Polyethylene Film features a self-lubricating surface with an ultra-low friction coefficient (0.05–0.15), chemical inertness to acids, alkalis, and solvents (except oxidizing acids), and negligible moisture absorption (<0.01%), ensuring hygiene and compliance in FDA-regulated environments. Lightweight at 0.93 g/cm³ density and engineered with molecular weights over 3,000,000 g/mol, this versatile UHMWPE Polyethylene Film excels in gas permeability, impact absorption, and corrosion resistance, making it ideal for protective barriers, conveyor linings, and electrical insulators. Discover how our thermally stable UHMWPE Polyethylene Film drives efficiency—visit teflonx.com for more.

Caratteristiche e vantaggi principali

Teflon X UHMWPE Polyethylene Film leverages advanced UHMWPE formulation to provide these pivotal attributes, emphasizing thermal stability, electrical insulation, and durability for seamless integration in high-stakes industrial uses:

- Stabilità termica: Maintains structural integrity and flexibility from -200°C to +80°C, with low thermal expansion to support consistent performance in fluctuating temperature machinery and cryogenic systems.

- Isolamento elettrico: High dielectric strength (20–30 kV/mm) and low conductivity ensure safe, reliable insulation for cables, motors, and electronic components, minimizing risks in power-intensive applications.

- High Wear Resistance: 15× superior abrasion resistance to carbon steel, coupled with self-lubrication, reduces friction and wear in dynamic parts like gears and slides.

- Low-Temperature Flexibility: Retains pliability and impact strength at sub-zero levels, preventing cracking in cold-chain logistics, automotive seals, and textile processing.

- Chemical and Corrosion Resistance: Inert to harsh chemicals, solvents, and moisture, protecting against degradation in chemical reactors and acidic environments.

- FDA Compliance and Hygiene: Non-toxic, odorless, and food-contact safe, meeting stringent standards for clean, contamination-free operations in regulated industries.

- Lightweight and High Strength: Low density with tensile yield strength of 19.3–23 MPa and elongation >300%, enabling easy handling and robust energy absorption in protective films.

- Low Friction Surface: Dynamic coefficient of 0.05–0.15 promotes smooth operation, comparable to PTFE, for lubricant-free efficiency in sliding mechanisms.

This resilient UHMWPE Polyethylene Film outperforms conventional insulators, blending thermal endurance with electrical reliability for innovative, cost-saving applications.

Applicazioni

Teflon X UHMWPE Polyethylene Film is purpose-built for environments requiring thermal stability and electrical insulation, powering advancements in key industries with its wear-resistant, flexible design:

- Industrial Machinery: Insulating films for motors, gears, and conveyor systems, leveraging high dielectric strength and low friction to enhance safety and reduce wear in automated production lines.

- Automotive Sector: Vibration dampeners, seals, and battery insulators, where thermal stability and impact resistance absorb shocks while providing electrical protection in engine compartments.

- Textile Processing: Wear strips and guide rails in weaving machines, benefiting from low-temperature flexibility and chemical resistance to maintain smooth fabric flow without adhesion.

- Elaborazione chimica: Protective linings and barriers in reactors and pipelines, ensuring corrosion-free operation and electrical insulation in solvent-heavy environments.

- Electrical and Power Systems: Cable wraps and component insulators, utilizing superior dielectric properties and thermal conductivity for reliable performance in high-voltage setups.

- Hygiene-Sensitive Packaging: FDA-compliant films for food and pharma wrapping, combining moisture resistance with easy-clean surfaces for sterile, efficient handling.

From automotive durability to chemical precision, our UHMWPE Polyethylene Film delivers versatile, high-performance solutions tailored to rigorous demands.

Specifiche tecniche

Below is a comprehensive table of standard parameters for Teflon X’s UHMWPE Polyethylene Film. Customized options, such as varied thicknesses or enhanced insulation grades, are available—contact us for bespoke UHMWPE Polyethylene Film specifications.

| Proprietà | Value/Range | Test Standard/Notes |

|---|---|---|

| Material Type | Ultra-High Molecular Weight Polyethylene (UHMWPE) | ASTM D4020 |

| Molecular Weight | >3,000,000 g/mol | Gel Permeation Chromatography |

| Densità | 0.93 g/cm³ | ASTM D792 |

| Tensile Yield Strength | 19.3–23 MPa | ASTM D638 |

| Allungamento a rottura | >300% | ASTM D638 |

| Shore D Hardness | 60–65 | ASTM D2240 |

| Impact Strength (Izod) | No Break (Unnotched) | Highest among thermoplastics |

| Coefficiente di attrito | 0.05–0.15 (Dynamic) | Comparable to PTFE |

| Resistenza all'usura | 15x Carbon Steel | Taber Abrasion Test |

| Operating Temperature | -200°C to +80°C | Continuous Use |

| Resistenza chimica | Excellent (Acids, Alkalis, Solvents) | Except Oxidizing Acids |

| Assorbimento d'acqua | <0.01% (24 hrs) | ASTM D570 |

| Spessore | 0.1–5 mm | Customizable |

| Larghezza | Up to 2 m | Roll or Sheet Format |

| Conformità FDA | Yes (Non-Toxic, Food Contact Safe) | 21 CFR 177.1520 |

| Porosity (Microporous) | 30–70% (Optional) | For Filtration Grades |

| Rigidità dielettrica | 20–30 kV/mm | ASTM D149 (Estimated for Sheets) |

Note: Values are typical and may vary based on processing and grade. For detailed datasheets, visit teflonx.com.

Perché scegliere Teflon X?

Teflon X excels in polymer film technology, developing our UHMWPE Polyethylene Film through exhaustive testing for thermal stability and electrical insulation that exceeds market leaders. This premium UHMWPE Polyethylene Film deploys effortlessly, cutting energy loss via low friction and bolstering safety with FDA-grade hygiene, all while withstanding extreme conditions for up to 50% longer service life. Our worldwide expertise, swift customization, and client-focused service position Teflon X as your premier partner for cutting-edge UHMWPE Polyethylene Film innovations.

Empower your projects with Teflon X’s reliable UHMWPE Polyethylene Film—browse our offerings at teflonx.com or connect via our Pagina Contattaci. For personalized advice, email Allison.Ye@teflonx.com.

Recensioni

Ancora non ci sono recensioni.