Panoramica del prodotto

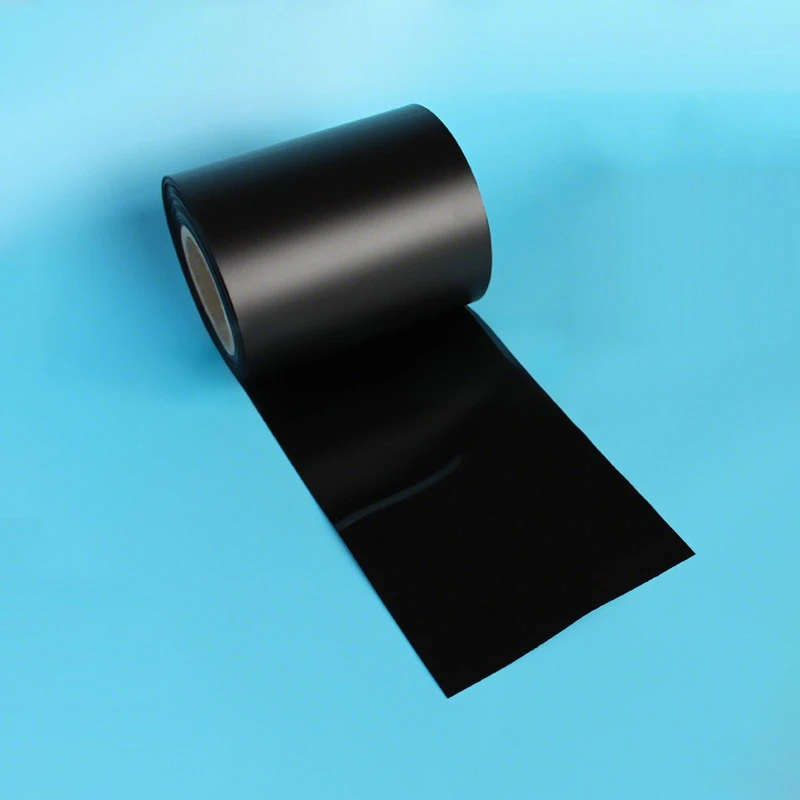

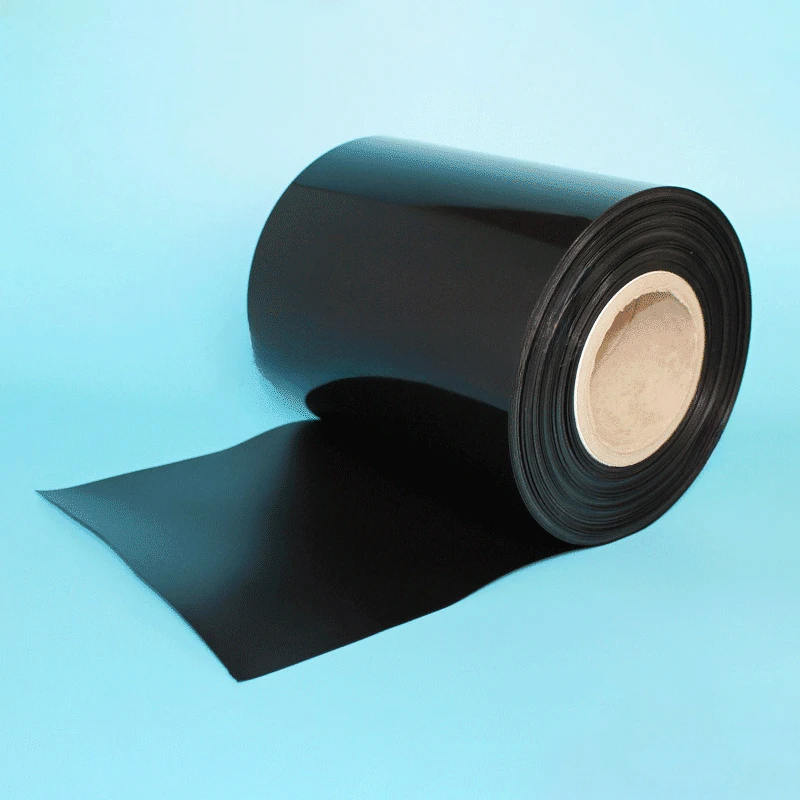

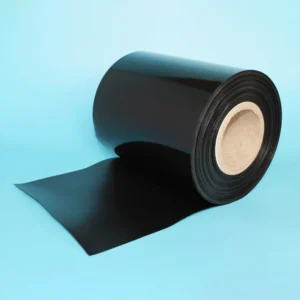

Discover unmatched resilience with Teflon X’s UPE Membrane Sheet, a state-of-the-art Ultra-High Molecular Weight Polyethylene (UHMWPE) membrane engineered for superior flexibility in extreme cold and robust chemical resistance. This premium UPE Membrane Sheet retains its ductility and performance down to -196°C, making it indispensable for cryogenic applications like liquid nitrogen handling, while its inherent chemical inertness shields against corrosion from acids, alkalis, solvents, and harsh industrial media. The non-adhesive surface of our UPE Membrane Sheet ensures effortless cleaning and minimal residue buildup, safeguarding hygiene in sensitive environments without compromising on durability or low moisture absorption.

Teflon X UPE Membrane Sheet features a microporous structure for enhanced permeability, combined with self-lubricating properties and abrasion resistance up to 15× that of carbon steel, extending service life in demanding setups. With molecular weights exceeding 3,000,000 g/mol and a lightweight density of 0.93 g/cm³, this versatile UPE Membrane Sheet excels in thermal stability from cryogenic lows to +80°C, low friction (0.05–0.15 coefficient), and FDA-compliant biocompatibility for safe, non-toxic use. Ideal for chemical processing equipment and protective linings, our UPE Membrane Sheet minimizes maintenance and downtime—elevate your operations today at teflonx.com.

Caratteristiche e vantaggi principali

Teflon X UPE Membrane Sheet is crafted from advanced UHMWPE to deliver these core advantages, focusing on extreme cold flexibility, chemical endurance, and hygienic non-adhesion for industrial and cryogenic excellence:

- Extreme Cold Flexibility: Maintains pliability and impact strength at -196°C without brittleness, perfect for liquid nitrogen systems and cryogenic storage where conventional materials fail.

- Superior Chemical Resistance: Highly inert to corrosive acids, alkalis, solvents, and moisture (<0.01% absorption), preventing degradation and ensuring longevity in aggressive chemical environments.

- Non-Adhesive Surface: Ultra-low surface energy repels contaminants, residues, and buildup, enabling quick, thorough cleaning in hygiene-critical applications like food processing and medical linings.

- High Abrasion and Impact Resistance: 15× tougher than carbon steel with no-break Izod strength, absorbing shocks and wear in abrasive flows or mechanical stresses.

- Self-Lubricating Properties: Low dynamic friction (0.05–0.15) reduces drag and eliminates lubricants, enhancing efficiency in sliding or dynamic membrane deployments.

- Stabilità termica: Operates reliably from -200°C to +80°C with minimal expansion, supporting diverse temperature-fluctuating processes without warping or loss of integrity.

- Microporous Permeability: Optional 30–70% porosity for selective filtration and breathability, while retaining mechanical robustness in protective UPE Membrane Sheet roles.

- Biocompatibility and Compliance: FDA-approved, non-toxic, and odorless for safe contact in medical, food, and environmental applications, with UV and microbial resistance.

This durable UPE Membrane Sheet outperforms standard polymers, blending cryogenic flexibility with chemical-proof hygiene for sustainable, high-stakes performance.

Applicazioni

Teflon X UPE Membrane Sheet is optimized for harsh, low-temperature, and corrosive scenarios, providing flexible, non-adhesive protection across vital sectors:

- Liquid Nitrogen Handling: Cryogenic liners and barriers in storage tanks and transport, leveraging extreme cold flexibility to prevent cracking and ensure safe containment.

- Chemical Processing Equipment: Membrane sheets for reactors, pipes, and vessels, resisting corrosion and facilitating easy cleaning in acid/alkali-heavy operations.

- Protective Linings: Anti-stick coatings for hoppers, chutes, and tanks in industrial handling, minimizing adhesion and abrasion for efficient material flow.

- Hygiene-Sensitive Environments: Liners in food processing and pharmaceutical setups, where non-adhesive surfaces reduce contamination risks and support sterile maintenance.

- Environmental and Wastewater Systems: Flexible barriers in cold-climate filtration, combining chemical resistance with permeability for durable pollutant separation.

- Medical and Lab Equipment: Cryogenic sample holders and protective wraps, benefiting from biocompatibility and low-friction hygiene in sub-zero biomedical storage.

From cryogenic precision to chemical resilience, our UPE Membrane Sheet enables reliable, low-maintenance solutions in extreme environments.

Specifiche tecniche

Below is a comprehensive table of standard parameters for Teflon X’s UPE Membrane Sheet. Tailored variants, including enhanced cryogenic grades or specific porosities, are available—contact us for customized UPE Membrane Sheet details.

| Proprietà | Value/Range | Test Standard/Notes |

|---|---|---|

| Material Type | Ultra-High Molecular Weight Polyethylene (UHMWPE) | ASTM D4020 |

| Molecular Weight | >3,000,000 g/mol | Gel Permeation Chromatography |

| Densità | 0.93 g/cm³ | ASTM D792 |

| Tensile Yield Strength | 19.3–23 MPa | ASTM D638 |

| Allungamento a rottura | >300% | ASTM D638 |

| Shore D Hardness | 60–65 | ASTM D2240 |

| Impact Strength (Izod) | No Break (Unnotched) | Highest among thermoplastics |

| Coefficiente di attrito | 0.05–0.15 (Dynamic) | Comparable to PTFE |

| Resistenza all'usura | 15x Carbon Steel | Taber Abrasion Test |

| Operating Temperature | -200°C to +80°C | Continuous Use |

| Resistenza chimica | Excellent (Acids, Alkalis, Solvents) | Except Oxidizing Acids |

| Assorbimento d'acqua | <0.01% (24 hrs) | ASTM D570 |

| Spessore | 0.1–5 mm | Customizable |

| Larghezza | Up to 2 m | Roll or Sheet Format |

| Conformità FDA | Yes (Non-Toxic, Food Contact Safe) | 21 CFR 177.1520 |

| Porosity (Microporous) | 30–70% (Optional) | For Filtration Grades |

| Rigidità dielettrica | 20–30 kV/mm | ASTM D149 (Estimated for Sheets) |

Note: Values are typical and may vary based on processing and grade. For detailed datasheets, visit teflonx.com.

Perché scegliere Teflon X?

Teflon X pioneers polymer membranes with our UPE Membrane Sheet, rigorously validated for cryogenic flexibility and chemical resistance that outshines industry norms. This high-performance UPE Membrane Sheet deploys seamlessly, cutting cleaning time by up to 70% via non-adhesive ease while enduring extreme conditions with zero compromise on hygiene or strength. Our global innovation, rapid prototyping, and expert guidance make Teflon X your ultimate source for resilient UPE Membrane Sheet that fuels progress.

Secure your edge with Teflon X’s adaptable UPE Membrane Sheet—peruse our selections at teflonx.com or submit inquiries on our Pagina Contattaci. For expert insights, email Allison.Ye@teflonx.com.

Recensioni

Ancora non ci sono recensioni.