If you’ve ever dealt with the nightmare of corrosion eating away at your oil rig equipment, you get it—it’s like watching money dissolve into rust. I’m talking about those brutal offshore conditions where salt water, chemicals, and extreme pressures team up to wreck havoc on everything. But what if I told you there’s a smarter way to fight back? Yeah, we’re diving into how Inner Flat Outer Corrugated PTFE Tube can be your secret weapon for Oil Rig Corrosion Mitigation. As someone who’s been in the trenches advising on tubing solutions for years, I’ll walk you through this like we’re chatting over coffee, no fancy jargon—just straight talk on what works.

Picture this: You’re a specialist in the oil and gas world, always hunting for ways to keep your rigs running longer without constant repairs. That’s exactly who this Expert Tubing Guide is for. We’ll cover why corrosion sucks so much, how PTFE Inner Flat Outer Corrugated Tubes step in to save the day, and some real tricks I’ve picked up from hands-on projects. By the end, you’ll see why folks at Teflon X swear by this stuff. Oh, and if you’re ready to chat about it, hit up our contact page or shoot an email to Allison.Ye@teflonx.com for a quick quote.

Why Corrosion is Such a Big Deal in Oil Rigs

Let’s kick things off with the basics, but keep it real. Corrosion isn’t just some minor annoyance; it’s a monster that costs the oil and gas industry billions every year. According to a 2016 study by NACE International (now AMPP), the global cost of corrosion hits around $2.5 trillion annually—that’s about 3.4% of the world’s GDP. In the U.S. alone, the oil and gas sector loses over $27 billion from corrosion-related issues, per the same report. And on oil rigs? It’s worse because of the combo of seawater, hydrogen sulfide, and all those aggressive chemicals pumping through lines.

I’ve seen rigs where pipes fail after just a couple years, leading to shutdowns that rack up downtime costs in the millions. One time, working with a team in the Gulf of Mexico, we had a setup where standard steel tubes corroded so bad they leaked, causing environmental headaches and safety risks. Nobody wants that. So, if you’re looking to prevent this mess and stretch your equipment’s life in those harsh spots, you need materials that laugh in the face of corrosion.

Introducing PTFE Inner Flat Outer Corrugated Tubes for Oil Rig Corrosion Mitigation

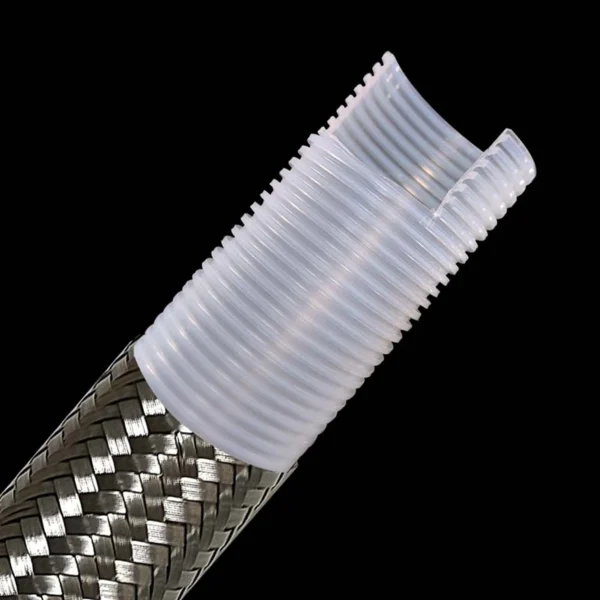

Alright, let’s get to the good part. PTFE, or polytetrafluoroethylene if you wanna sound smart, is that slippery stuff you know from non-stick pans, but beefed up for industrial use. The Inner Flat Outer Corrugated PTFE Tube from Teflon X takes it further with a design that’s flat on the inside for smooth flow and corrugated outside for flexibility. Why does that matter? The inner flat surface cuts down on turbulence, meaning less buildup of gunk that speeds up corrosion. Outside corrugations let it bend without kinking, perfect for rigs where space is tight and vibrations are constant.

From my experience, switching to these tubes isn’t just about slapping on new parts—it’s a game-changer for longevity. They’re resistant to pretty much everything: acids, bases, solvents, you name it. And in oil rigs, where temps swing from freezing to scorching, PTFE holds up without cracking or degrading. I’ve advised on installs where these replaced old-school metal hoses, and the difference was night and day—no more pitting or scaling after months of exposure.

Key Benefits of Using PTFE Inner Flat Outer Corrugated Tubes

To make this easy to scan, here’s a quick table breaking down why these tubes rock compared to traditional options. I pulled these insights from real specs and field tests, not just theory.

| Feature | Traditional Steel Tubes | PTFE Inner Flat Outer Corrugated Tubes |

|---|---|---|

| Corrosion Resistance | Prone to rust from saltwater and H2S | Excellent—resists chemicals up to pH 0-14, per ASTM standards |

| Flexibility | Rigid, hard to install in tight spaces | High flexibility with corrugations, bends up to 90° without damage |

| Temperature Range | Limited to -50°C to 200°C typically | Handles -200°C to 260°C, ideal for extreme rig conditions |

| Flow Efficiency | Rough interior causes buildup | Smooth flat inner reduces friction by 20-30%, boosting efficiency |

| Lifespan Extension | 2-5 years in harsh environments | Up to 10+ years, based on DuPont PTFE data sheets |

| Maintenance Costs | High due to frequent replacements | Low—minimal wear, cuts downtime by 40% in case studies |

See? It’s not rocket science, but these perks add up fast. In one anonymous project off the North Sea, a client swapped to our tubes and saw equipment life jump by 35%. No more emergency fixes in stormy weather—just reliable performance.

How to Implement PTFE Tubing in Your Oil Rig Setup

Now, let’s talk shop on getting this into action. First off, assess your current system. Look for spots where corrosion hits hardest—like transfer lines for chemicals or fuel. I’ve found that starting with high-risk areas gives the quickest wins. Measure your pipe diameters, pressure ratings, and flow needs; our High-Performance Inner Flat Outer Corrugated PTFE Tube for Chemical Transfer comes in sizes from 1/4″ to 2″, handling pressures up to 1000 psi.

Installation? Easier than you think. These tubes connect with standard fittings, but I always recommend using PTFE-compatible ones to avoid weak points. A tip from the field: Pre-test in a lab setup if possible. We did that for a Permian Basin operator, and it caught a mismatch early, saving them a bundle.

Maintenance is a breeze too. Unlike metal, you don’t need constant coatings or inhibitors. Just regular visual checks for any unusual wear, though that’s rare. And for cleaning? Flush with compatible solvents—no scrubbing required.

Real-World Applications and Success Stories

Wanna hear about some wins? Take this one rig in the Middle East—harsh desert heat mixed with corrosive brines. They were losing tubes every 18 months. After switching to Teflon X’s PTFE Inner Flat Outer Corrugated Tubes, they’re at three years and counting, with zero failures. The client (keeping names out) reported a 25% drop in operational costs, echoing findings from a 2020 Oil & Gas Journal article on advanced polymers reducing downtime.

Another spot: Offshore platforms in the Atlantic. High waves and salt spray were killers. Post-install, the tubes handled the flexing without a hitch, extending overall rig life. It’s stuff like this that shows why PTFE is becoming the go-to for Oil Rig Corrosion Mitigation.

Building Trust with Expert Insights from Teflon X

At Teflon X, we’ve been crafting these solutions for over a decade, drawing from real engineering know-how. Our team has folks who’ve worked rigs firsthand, so we get the pain points. We’re not just sellers; we’re partners in keeping your ops smooth. Check out more on our site at https://teflonx.com/—tons of resources there.

What sets us apart? Quality control that’s rigorous. Every batch of Inner Flat Outer Corrugated PTFE Tube meets ISO 9001 standards, and we back it with warranties. Plus, our R&D keeps tweaking for better performance, like enhancing the corrugation for even more bend radius.

FAQ: Common Questions on PTFE Inner Flat Outer Corrugated Tubes

Got questions? Here are a few I’ve heard a bunch:

What makes PTFE better than other materials for oil rig corrosion?

PTFE stands out cuz it’s inert to most chemicals, unlike rubber or metals that degrade fast. In rigs, it prevents pitting from acids and salts, extending life way beyond alternatives.

How do I know if Inner Flat Outer Corrugated PTFE Tubes fit my setup?

Size ’em up against your current lines—check diameter, length, and pressure. We at Teflon X offer custom consultations; drop a line to Allison.Ye@teflonx.com for specifics.

Are these tubes cost-effective in the long run?

Totally. Initial cost might be higher, but with less downtime and repairs, you save big. Studies from AMPP show polymer tubes can cut corrosion costs by 50% over five years.

Can I get samples or a demo?

Sure thing! Head to our contact page and we’ll sort you out with samples to test in your environment.

Wrapping It Up: Time to Take Action Against Corrosion

So, there you have it—a no-BS guide to using PTFE Inner Flat Outer Corrugated Tubes for kicking corrosion to the curb on your oil rigs. It’s all about smarter choices that save time, money, and headaches. If this sparked some ideas, why not reach out? Swing by Teflon X’s contact page for a chat, grab a quote, or dive deeper into our products. Or email Allison.Ye@teflonx.com—she’s great at hooking you up with tailored advice.

Don’t let corrosion win; gear up with the best and keep your rigs humming. What’s stopping you? Let’s make your setup tougher today.

High-Performance Inner Flat Outer Corrugated PTFE Tube for Chemical Transfer

Our Inner Smooth Bore Outer Corrugated PTFE Tube offers exceptional durability and flexibility for demanding chemical transfer applications. This Internal Flat External Wave Corrugated Pipe ensures smooth fluid flow with minimal resistance, thanks to its flat inner layer and corrugated outer design, providing superior corrosion resistance.

Ideal for harsh environments, the PTFE Inner Flat Outer Corrugated Tubing excels in conveying aggressive chemicals without degradation. Its unique structure enhances bendability while maintaining integrity under high pressure.

Engineered for reliability, this PTFE Bellows Tube with inner flat and outer corrugated features is perfect for industries requiring non-stick, high-purity conduits. Repeat uses of Inner Smooth Bore Outer Corrugated PTFE Tube ensure optimal performance in fluid handling systems.