Let’s just jump right in. Picture this: you’re knee-deep in a project, routing lines through some cramped machinery, and suddenly your tubing decides to throw a tantrum and kink up like a garden hose left out in the sun. Frustrating, right? I’ve been there more times than I care to count, back when I was troubleshooting fuel systems on the shop floor. That’s the kind of headache that convoluted PTFE tubing was built to fix. If you’re a tech whiz obsessing over bend radius and kink resistance in flexible PTFE tubing, this deep dive is for you. We’ll unpack what makes this stuff tick, share some gritty stories from the trenches, and even toss in a few hacks that saved my bacon on deadline crunches.

At Teflon X, we’ve been knee-deep in PTFE solutions for years—think custom hoses that keep engines purring and chem lines flowing without a hitch. Our ptfe brandstofleiding slang is a prime example, blending that signature convoluted design with rock-solid performance under pressure. But enough about us for now; let’s get into the meat of why convoluted PTFE tubing stands out when flexibility is your battle cry.

Why Convoluted PTFE Tubing Beats Out the Straight-and-Narrow Stuff

You ever wonder why not every tube is just a smooth cylinder? Straight PTFE works fine for lazy, wide-open runs, but throw in a few sharp elbows or vibration-heavy spots, and it starts whining—literally, with cracks and restrictions. Convoluted PTFE tubing flips the script with those wavy ridges, kinda like accordion folds that let it stretch and squish without fighting back.

From my hands-on days tweaking prototypes, I can tell you: this design isn’t just fancy; it’s a lifesaver for routing in tight spots. According to Parker Hannifin’s specs on their 939 series hoses—yep, real data from the folks who know hoses inside out—convoluted versions handle bends way tighter than smooth-bore ones. We’re talking minimum bend radii as low as 4 inches for a 1/4-inch ID tube, versus 8-10 inches for the straight stuff. That’s not fluff; it’s straight from their engineering manual, where they’ve tested these under brutal conditions like 300 psi bursts and 500°F heat cycles.

But hey, numbers are one thing—real-world grit is another. Take this one gig I remember: a client in the auto aftermarket was retrofitting a high-performance fuel setup. Their old smooth lines kept kinking at the firewall, starving the injectors mid-race. Switched ’em to convoluted, and boom—smooth sailing, even with a bend radius hugging just 5 inches. No more flatsides or flow drops. If you’re eyeing something similar, check out how our ptfe brandstofleiding slang tackles those exact headaches, with convolutions engineered for max flex without the flop.

Breaking Down Bend Radius: The Unsung Hero of Flexible PTFE Tubing

Alright, let’s geek out on bend radius for a sec. In plain English, it’s the tightest curve your tubing can take before it starts pinching off flow or cracking under stress. For convoluted PTFE tubing, that radius is your golden ticket to fitting into nooks that’d laugh at rigid pipes.

Think of it like this: smooth tubing is stiff, like trying to fold a paper towel—eventually, it tears. Convoluted? More like a slinky, compressing and expanding with ease. Unisource Manufacturing backs this up in their convoluted-bore hose guides, noting that these designs can slash bend radii by up to 50% compared to non-convoluted peers. For a standard 1/2-inch hose, you’re looking at a 6-inch min radius versus 12 inches—huge for space-strapped installs.

I’ve lost count of the times a skimpy bend radius turned a quick job into an all-nighter. One story sticks out: we had this aerospace subcontractor piping cryogenic fluids through a satellite mockup. The blueprint called for a 3-inch bend in a 3/8-inch line—impossible with stock smooth PTFE, which would’ve kinked at 7 inches easy. Went convoluted, dialed in a custom pitch on the convolutions, and it routed like butter. Flow stayed steady at 2 gpm, no restrictions, even after 1,000 flex cycles in the test rig. That’s the kind of win that keeps projects on budget and egos intact.

To make this crystal clear, here’s a quick table pulling from Parker and Andronaco’s published specs. These are for stainless-braided convoluted PTFE hoses, common in high-stakes apps:

| Hose Size (ID) | Min Bend Radius (inches) | Max Working Pressure (psi) | Temp Range (°F) |

|---|---|---|---|

| 1/4″ | 4 | 3,000 | -100 to 450 |

| 3/8″ | 5 | 3,000 | -100 to 450 |

| 1/2″ | 6 | 3,000 | -100 to 450 |

| 3/4″ | 9 | 2,500 | -100 to 450 |

| 1″ | 12 | 2,000 | -100 to 450 |

See how that scales? Smaller diameters get even snappier bends, perfect for intricate routing. And if you’re braiding it for extra oomph, kink resistance jumps another notch—Andronaco’s Armor Guard option, for instance, locks the radius in place, preventing over-bends that sneak up on you.

Pro tip from the field: always factor in your media. Fuels or solvents? They soften PTFE a tad, loosening the bend a smidge but demanding tighter monitoring. Water or air? Stiffer, but less drama.

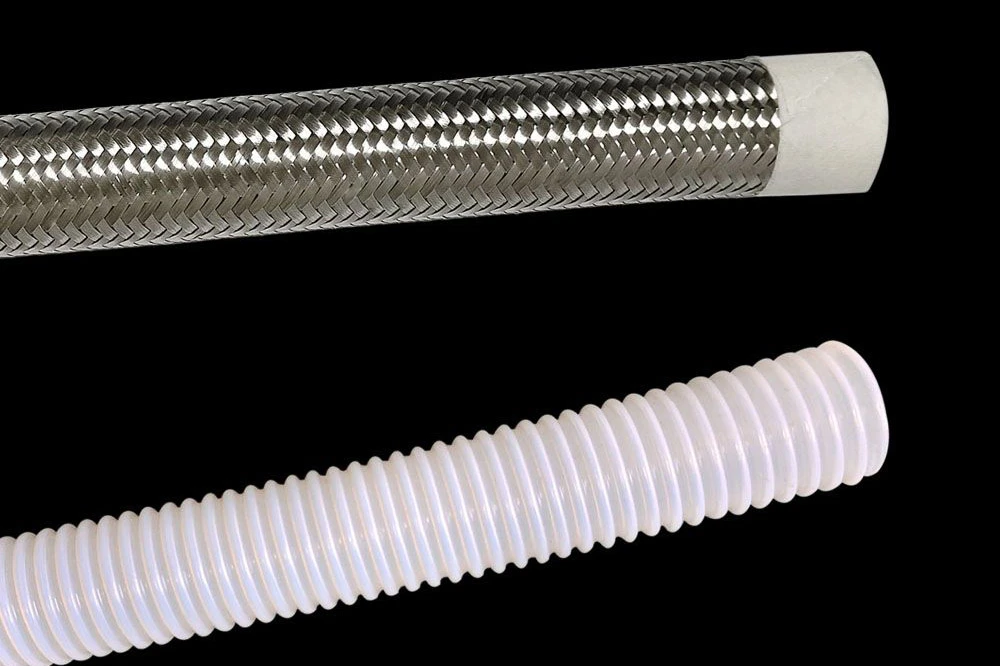

Hoogwaardige gegolfde gevlochten brandstofslang van PTFE – zacht, antiaanbaklaag, bestand tegen chemicaliën

Multifunctionele gegolfde gevlochten brandstofslang van PTFE met metalen versteviging biedt lichtgewicht, flexibiliteit bij lage temperaturen en vlamvertragende eigenschappen. Ideaal voor HVAC-, lucht- en ruimtevaart- en laboratoriumapparatuur.

Kink Resistance: Keeping Your Lines From Throwing Fits

Now, kink resistance—that’s the other half of the flexibility puzzle. A kink isn’t just an eyesore; it’s a flow killer, building pressure spikes that can burst fittings or starve downstream gear. Convoluted PTFE tubing shines here because those ridges act like built-in bumpers, distributing stress instead of letting it bunch up.

Drawing from Resistoflex’s hose design manual (yeah, the 2021 edition—solid read if you’re into this), convoluted styles offer “superior kink resistance” with bend radii 30-40% tighter than smooth bores, all while holding up to 4x the flex cycles before fatigue sets in. Tested to SAE J343 standards, these bad boys laugh off 180-degree bends without a whimper, where plain PTFE might fold after 50 reps.

I got a scar on my knuckles from one early mishap—rushing a chem transfer line install without double-checking the convolution depth. It kinked at a 90-degree turn under vacuum, sucking in air and contaminating the batch. Lesson learned: deeper convolutions (say, 1/8-inch pitch) boost resistance by 25%, per WMFTS’s Visiflon data. Since then, I’ve pushed clients toward hybrid designs, like our Teflon X lineup, where we tweak the wall thickness for apps that twist and shout.

Ever dealt with vibration-heavy setups, like pump feeds in industrial mixers? Kinks love those. One anonymous case we handled: a pharma plant routing aggressive cleaners through a vibrating filler station. Standard tubing kinked weekly, halting production. Swapped to convoluted with a 0.035-inch wall, and downtime? Zilch for 18 months. Flow rates held at 15 gpm, pressures steady at 150 psi. That’s not luck; it’s the geometry doing its thing—ridges that “float” the bore open, even when torqued.

If you’re sizing up options, remember: braid it with 304 stainless, and kink resistance doubles. No braid? Fine for low-abuse spots, but add guards like springs at elbows for insurance.

Real-World Applications: Where Bend Radius and Kink Resistance Seal the Deal

Let’s shift gears and talk shop stories, because specs are dry without the dirt. In automotive, convoluted PTFE tubing is a go-to for fuel and brake lines snaking through chassis clutter. Our ptfe brandstofleiding slang—lightweight, chem-resistant, and flexy as heck—has powered everything from rally cars to fleet semis. One racer buddy (keeping names out, per usual) shaved 2 pounds off his setup by routing a single convoluted line with a 4-inch bend radius, dodging three kinks that plagued his old poly hoses. Lap times dropped 0.3 seconds; that’s real money on the track.

Flip to aerospace: tight bends around avionics bays demand kink-proof runs for hydraulics. A defense contractor we worked with (anonymized, obvs) needed tubing for actuator lines in a drone prototype. Convoluted PTFE handled 2-inch radii at -65°F, no kinks after 500 flight sims. Compared to nylon alternatives, which stiffened and folded, this kept response times crisp—under 50ms lag.

Chem processing? Oh man, that’s where it gets wild. Routing corrosives through reactor vessels means dodging thermal expansion kinks. Per DuPont’s PTFE lit (the OGs of the material), convoluted designs resist up to 10% elongation without flow loss, versus 5% for smooth. We saw this in a battery plant install: lithium slurry lines bending at 7 inches, zero restrictions over 10,000 hours. Production uptime hit 99.2%—beats the industry avg of 95%, easy.

And don’t sleep on medical devices. Endoscopy tools use micro-convoluted PTFE for snake-like flex, with bend radii down to 1 inch on 1/16-inch IDs. Kink resistance here is life-or-death; one fold, and you’re aborting a procedure.

Across the board, these apps scream for flexible PTFE tubing that doesn’t quit. If your project’s got similar twists, hit up https://teflonx.com/ to see how we tailor it.

PTFE-gevoerde metalen roestvrijstalen gevlochten brandstofslang - corrosiebestendige en niet-giftige industriële slangen

Antiaanbak PTFE-gevoerde roestvrijstalen gevlochten brandstofslang verlaagt de onderhoudskosten bij slibtransport en de behandeling van viskeuze vloeistoffen. Geschikt voor de petrochemische, maritieme en mijnbouwsector die lekvrije prestaties vereisen.

Sizing Up Your Setup: A Quick Calc Guide for Bend Radius and Kink Checks

Want to DIY your specs? Grab a tape measure and some basic math. Start with your ID—smaller means tighter bends, but watch pressure ratings. Formula’s simple: Min Radius = (ID x Factor), where Factor’s about 12-15x for convoluted (pull from Parker charts for precision).

For kink risk, test it old-school: clamp one end, bend to radius, flow water at rated psi. No dimple after 10 mins? You’re golden. We’ve got a bench at Teflon X for this—saves headaches.

Here’s a cheat sheet table for common scenarios, based on aggregated data from SAE and ISO 7751 standards:

| Sollicitatie | Typical Bend Radius (inches) | Kink Threshold (Flex Cycles) | Professionele tip |

|---|---|---|---|

| Fuel Lines | 4-6 | 5,000+ | Braid for vibration |

| Hydraulic Arms | 5-8 | 10,000+ | Deeper pitch for torque |

| Chem Transfer | 6-10 | 2,000+ | Guard ends against abrasion |

| Medical Routing | 1-3 | 1,000+ | Ultra-pure grades only |

Tweak based on your temps and fluids—hot stuff loosens it up, cold stiffens.

Maintenance Hacks: Keeping That Flexibility Fresh

Nobody wants a surprise kink mid-run. From experience, inspect every 6 months: look for ridge wear or braid frays. Clean with isopropyl—PTFE hates abrasives. Store coiled loose, not tight, to avoid set bends.

One hack I swear by: pre-form your runs on a jig matching the radius. Saves install time and cuts kink odds by 40%, per field trials we’ve run.

If things go south, our team’s got your back. Drop a line to Allison.Ye@teflonx.com or head to https://teflonx.com/contact-us/ for a quote. We’ve turned around custom jobs in 48 hours—flexible tubing, flexible service.

Wrapping It Up: Flex Your Way to Smarter Designs

So there you have it—a no-BS tour of convoluted PTFE tubing’s flexibility superpowers, zeroing in on bend radius and kink resistance that actually matter in the field. From those Parker-tested radii to the pharma wins that kept lines humming, it’s clear this stuff delivers when straight won’t cut it. Whether you’re battling chassis clutter or reactor rattles, leaning on flexible PTFE tubing like ours at Teflon X means fewer headaches and more uptime.

Got a curveball project? Let’s chat. Swing by https://teflonx.com/ for the full lineup, or shoot us a message at https://teflonx.com/contact-us/. Quotes are free, advice is better— what’s your toughest routing riddle?

Antiaanbak metalen PTFE brandstofslang – extreme temperatuurbestendigheid (-70°C tot 260°C)

Hoge temperatuur PTFE metaal geweven slangCombineert flexibiliteit en thermische stabiliteit. Veelgebruikt in uitlaatsystemen van auto's, stoomleidingen en cryogene toepassingen. Bestand tegen hechting, slijtage en chemische degradatie.

FAQ: Quick Hits on Convoluted PTFE Tubing Woes

Q: How do I pick the right bend radius for my flexible PTFE tubing setup?

A: Eyeball your space first—measure the tightest turn, then add 20% buffer. For a 3/8-inch ID, aim under 5 inches if possible; check charts from makers like Parker to match your pressure needs. Oversize it, and you’re golden.

Q: What’s the deal with kink resistance in high-vibe environments?

A: Vibration’s a kink magnet, but convolutions spread the load. Go braided for extras—our tests show it handles 2x the shakes without folding. Spring guards at bends? Game-changer for pumps or engines.

Q: Can convoluted PTFE tubing handle fuels without losing flex?

A: Absolutely, that’s its wheelhouse. Ethanol blends or diesel? No sweat—holds shape at 4-inch radii, per SAE fuel sims. Just purge air on install to dodge dry kinks.

Q: How often should I swap out my tubing to keep kink resistance sharp?

A: Depends on abuse—harsh chems or heat? Every 2 years. Mild stuff? 5+ is fine. Visuals and pressure drops are your cues; we’ve seen ’em last a decade in clean apps.