Industrial Grade PTFE Fuel Line for Chemical Processing Plants

In the high-stakes environment of chemical processing, the integrity of your fluid transfer systems determines the safety and efficiency of your entire operation. At Teflon X, we specialize in manufacturing high-performance transfer solutions designed to withstand the most aggressive industrial environments. Our PTFE Fuel Line for Chemical Processing Plants is engineered to deliver unmatched resistance to corrosive chemicals, extreme temperatures, and mechanical stress.

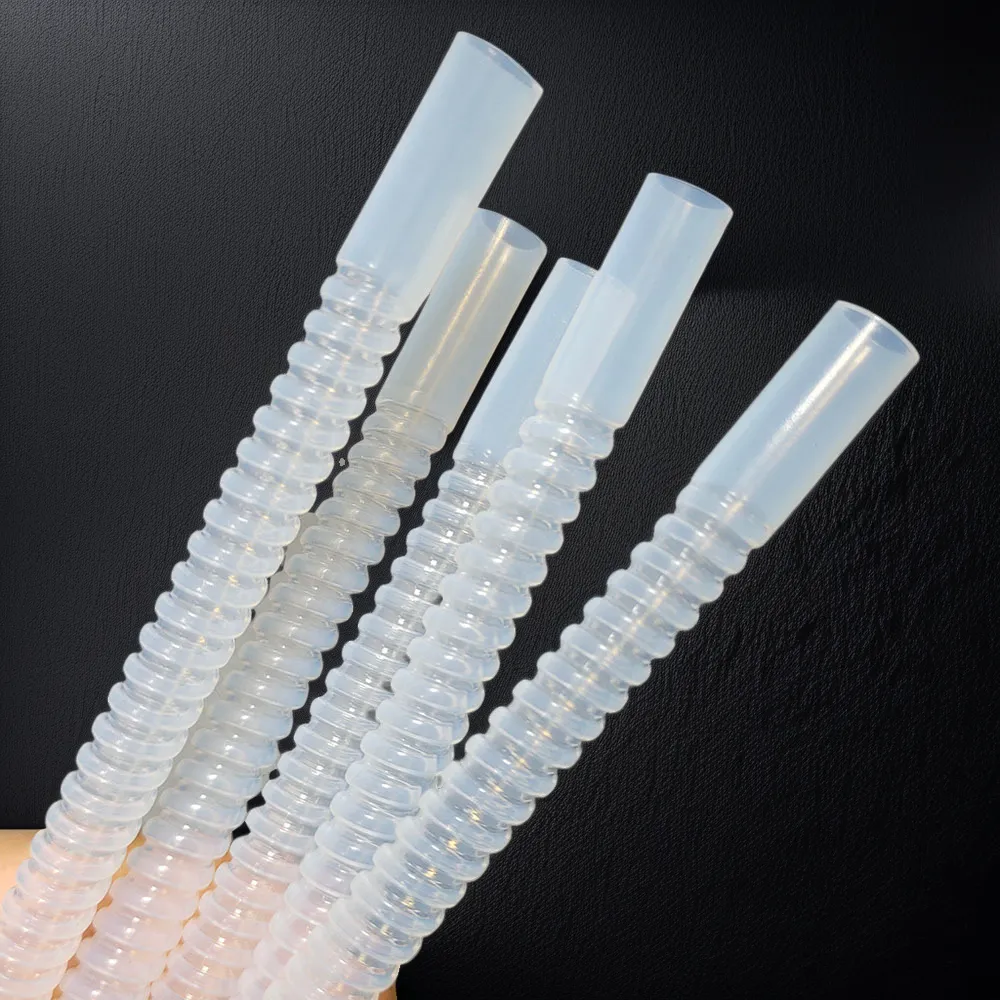

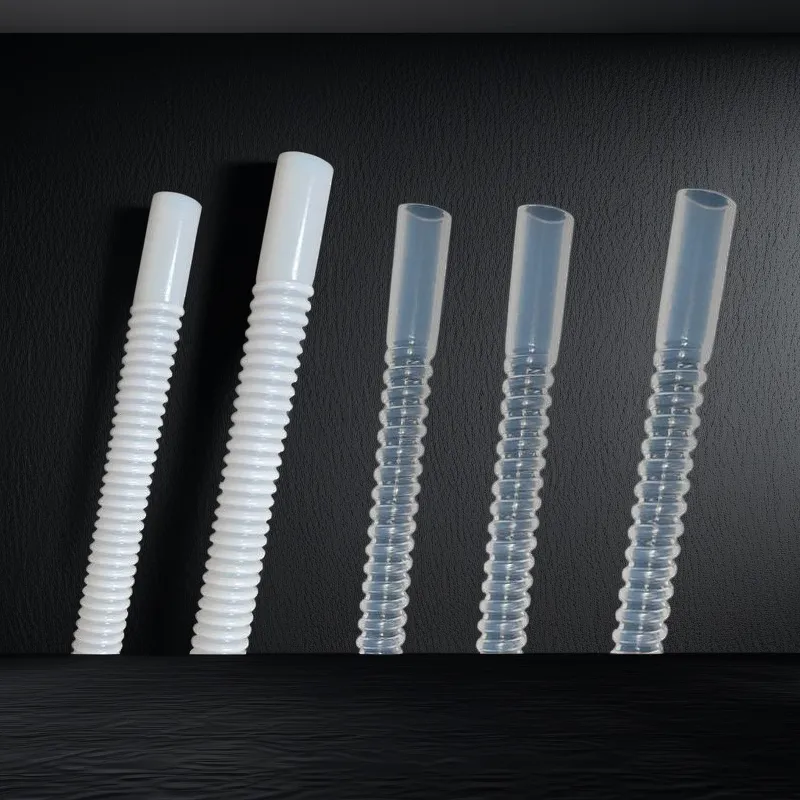

Whether you are transporting volatile solvents, concentrated acids, or high-purity pharmaceutical ingredients, our advanced ptfe corrugated fuel hose provides the reliability your facility demands. By utilizing the unique properties of Polytetrafluoroethylene (PTFE), we offer a solution that far exceeds the capabilities of standard rubber or metallic hoses.

Unrivaled Chemical Resistance with Teflon Fuel Hose Technology

The primary challenge in chemical plants is finding a hose material that does not react with the medium being transferred. Our teflon fuel hose is constructed from premium virgin PTFE resins, which are chemically inert to nearly all industrial chemicals, solvents, and corrosives. From strong acids like Hydrochloric and Sulfuric acid to aggressive bases and hydrocarbons, our ptfe fuel line ensures that the fluid remains pure and the hose wall remains intact.

This chemical inertness also means that our hoses are ideal for multi-purpose lines. Because the inner surface is non-stick and non-porous, it allows for easy cleaning and sterilization. A simple flush is often all that is required to switch from one chemical batch to another without the risk of cross-contamination, a critical feature for batch processing plants.

The Advantage of the Corrugated Fuel Tube Design

Rigid piping systems in chemical plants are often susceptible to failure due to thermal expansion, vibration from heavy pumps, or settling of storage tanks. Our corrugated fuel tube design addresses these mechanical challenges head-on. The helical convolution of the inner core imparts exceptional flexibility to the hose assembly.

This flexibility allows the ptfe corrugated fuel hose to act as a vibration dampener, isolating sensitive equipment like load cells, pumps, and reactors from stress. Furthermore, the corrugated fuel tube creates a self-cleaning effect; the spiral shape helps to maintain flow turbulence that prevents the settling of particulates or viscous materials, ensuring consistent flow rates even with difficult media.

Durability Under Extreme Conditions

Safety is paramount at Teflon X. To protect the inner PTFE liner from external physical damage and to increase the pressure containment capabilities, our hoses are reinforced with high-tensile stainless steel braiding (SS304 or SS316). For extremely harsh environments, we can also offer polymer braidings (like Polypropylene or PVDF) or fire-sleeves upon request.

This robust construction enables our ptfe fuel line to withstand severe thermal cycling. Chemical reactions often involve rapid temperature changes, and our hoses remain stable and flexible from cryogenic temperatures up to +260°C. This prevents the “cold flow” or brittleness often seen in other plastic hoses.

Key Features and Benefits

- Broad Chemical Compatibility: The teflon fuel hose resists attack from virtually all chemicals (pH 0-14), ensuring long service life and reduced maintenance costs.

- Superior Flexibility: The unique geometry of the corrugated fuel tube allows for tight bend radii without kinking, making installation in confined plant spaces easier.

- Safety Compliance: Available with anti-static (carbon-conductive) liners to dissipate static electricity buildup when transferring non-conductive fluids at high velocity.

- Temperature Resilience: Operates flawlessly in extreme heat or freezing environments without losing mechanical properties.

- Low Friction Coefficient: The smooth, non-stick nature of PTFE minimizes pressure drops across the system, improving energy efficiency for pumps.

Technical Specifications

We understand that every chemical plant has unique requirements. Below are the standard specifications for our Industrial Series ptfe corrugated fuel hose. Custom lengths and assemblies are our specialty.

| Parameter | Specification Details |

|---|---|

| Liner Material | Virgin PTFE (White) or Anti-Static Conductive PTFE (Black) |

| Reinforcement | Single or Double Stainless Steel Braid (AISI 304/316) |

| Construction Type | Helical corrugated fuel tube |

| Temperature Range | -70°C to +260°C (-94°F to +500°F) |

| Diameter Range (ID) | 1/2″ (DN15) to 6″ (DN150) |

| Vacuum Rating | Full Vacuum rated (up to certain diameters) |

| End Fittings | Flanged (ANSI 150/300, DIN), Camlock, Tri-Clamp, NPT/BSP Threads |

Applications in Chemical Processing

Our ptfe fuel line products are currently serving in a wide array of industrial applications, including:

- Loading and unloading of railcars and tanker trucks.

- Flexible connections for weighing systems and load cells.

- Steam transfer lines for heating jackets.

- Acid and alkali transfer lines in pickling lines.

- Solvent recovery systems.

Contact Us for Engineering Support

Selecting the correct hose for hazardous chemical transfer is a decision that impacts safety and profitability. Teflon X offers comprehensive engineering support to ensure you choose the right teflon fuel hose for your specific media and pressure requirements.

To learn more about our manufacturing capabilities, please visit our website at teflonx.com. For immediate assistance, quotes, or to request a product catalog, please navigate to our Contact Page or email our sales team directly at allison.ye@teflonx.com.

Reviews

There are no reviews yet.