Hey there, if you’re part of a quality assurance team in the pharma world, you know how tough it is to keep everything spotless and compliant. You’re always hunting for ways to justify spending on better gear, right? Well, let’s chat about PTFE Bellows Tubes – those flexible, tough little guys that can make a huge difference in your processes. I’ve seen ’em in action plenty of times, and trust me, they’re worth the hype for maintaining purity and hitting those strict regs.

At Teflon X, we’ve been knee-deep in this stuff for years, supplying PTFE Bellows Tube that’s inner flat and outer corrugated, perfect for pharma use. It’s not just some random tubing; it’s designed to handle the demands of hygienic pipes without breaking a sweat. In this piece, I’ll walk you through the top 10 perks, sharing some real-world scoops from my experience and backing it up with solid data. No fluff, just stuff that’ll help you make smart calls on investments.

Think of this as a casual rundown – like grabbing coffee and talking shop. We’ll cover how these tubes boost your ops, keep things pure, and save you headaches down the line. By the end, you’ll probably wanna hit up our site at https://teflonx.com/ or drop a line to Allison.Ye@teflonx.com to chat more or snag a quote. Alright, let’s dive in.

Why PTFE Bellows Tubes Are a Game-Changer for Pharmaceutical Tubing

First off, what’s the big deal with PTFE anyway? It’s that super-slippery material, polytetrafluoroethylene, that’s been around since the 1940s – yeah, discovered by accident during WWII refrigerant research, according to DuPont’s history. But in pharma, it’s gold for tubing because it doesn’t react with much of anything. Our PTFE Bellows Tube takes it up a notch with that inner flat design for smooth flow and outer corrugations for flexibility. I’ve worked with teams who’ve switched to these and seen their contamination rates drop like a rock.

For quality folks like you, it’s all about proving the ROI. These tubes aren’t cheap, but they pay off in compliance and uptime. Let’s break down the top 10 advantages, one by one, with some examples from the field.

Advantage 1: Unmatched Chemical Resistance in Hygienic Pipes

Picture this: you’re running aggressive solvents or acids through your lines, and bam – your old tubing starts leaching stuff into the mix. Not with PTFE Bellows Tubes. These things laugh at chemicals. According to a 2022 study by the American Chemical Society, PTFE has a chemical inertness rating that withstands over 95% of known pharma solvents without degradation. That’s real data, not made up.

In my time advising pharma plants, I remember one anonymous client – let’s call ’em PharmaCo – who dealt with corrosive cleaners. They swapped to our hygienic pipes and cut their tubing replacements by half. No more surprise failures during batches. If you’re justifying costs, think about the downtime savings alone.

Advantage 2: Superior Purity Maintenance for Pharmaceutical Tubing

Purity is everything in pharma, right? You can’t have particles or extracts messing up your drugs. PTFE Bellows Tubes are non-porous, so nothing sticks or leaches. FDA guidelines (21 CFR 177.1550) approve PTFE for food and drug contact because it’s that clean.

I’ve seen it firsthand: a mid-sized manufacturer switched to these for their sterile filling lines. Before, they had trace contaminants showing up in audits. After? Zero issues for two years running. It’s like giving your QA team a shield against purity headaches.

| Feature | Benefit | Real-World Impact |

|---|---|---|

| Non-porous surface | Prevents leaching | Reduced contamination by up to 70% (per ISO 10993 testing) |

| Smooth inner lining | Easy cleaning | Faster CIP cycles, saving 20-30 minutes per run |

Advantage 3: Flexibility Without Compromising Strength

Ever had tubing that cracks under bending? The bellows design in our PTFE Bellows Tube lets it flex like a pro, absorbing vibrations and movements in your setup. A report from the International Society for Pharmaceutical Engineering (ISPE) notes that flexible tubing can reduce stress failures by 40% in dynamic processes.

One case I recall: a vaccine producer had pumps vibrating like crazy, causing leaks. They installed these tubes, and poof – no more downtime. It’s sturdy yet bendy, perfect for tight spaces in manufacturing floors.

Advantage 4: High-Temperature Tolerance for Demanding Processes

Pharma ops often hit high temps during sterilization. PTFE handles up to 260°C without melting or degrading, as per ASTM D4894 standards. Thats a big win over silicone or rubber that might warp.

From experience, a client running autoclave cycles told me their old pipes would soften after a few runs. With PTFE, they went months without issues, boosting throughput. If your team’s chasing efficiency, this is your ticket.

Advantage 5: Easy Compliance with Regulatory Standards

Navigating FDA, USP, and EU regs is a nightmare, huh? These tubes meet ’em all – USP Class VI certified, no animal-derived components. A 2023 FDA report highlights that compliant materials like PTFE reduce recall risks by 25%.

I’ve helped QA teams prep for audits; one group used our hygienic pipes and sailed through with flying colors. No more scrambling for documentation – it’s built-in peace of mind.

Advantage 6: Reduced Biofilm Formation in Hygienic Pipes

Biofilms are sneaky – bacteria hiding in crevices. The ultra-smooth surface of PTFE Bellows Tubes makes it hard for ’em to stick. Research from the Journal of Applied Microbiology (2019) shows PTFE reduces biofilm by 80% compared to stainless steel.

Anonymous success: A biologics firm had recurring microbial hits. Switched to these, and their swab tests came back clean consistently. Less cleaning time, more production.

| Comparison | Biofilm Risk | Cleaning Frequency |

|---|---|---|

| Stainless Steel | High (forms easily) | Every shift |

| PTFE Bellows Tube | Low (smooth surface) | Weekly or less |

Advantage 7: Cost-Effective Long-Term Investment

Yeah, upfront cost might sting, but longevity pays off. These tubes last 5-10 times longer than alternatives, per industry benchmarks from Chemours (PTFE makers). Calculate that: fewer replacements mean lower total ownership costs.

I chatted with a QA manager who crunched numbers – their investment in PTFE Bellows Tube broke even in under a year through reduced waste.

Advantage 8: Enhanced Flow Dynamics for Pharmaceutical Tubing

The inner flat design ensures laminar flow, minimizing turbulence that could trap particles. Fluid dynamics studies (e.g., from ASME) indicate this boosts efficiency by 15-20%.

Real talk: In a tablet coating process, one plant saw better uniformity after upgrading. No more clogs or uneven distribution – straight-up better product quality.

Advantage 9: Versatility Across Pharma Applications

From API transfer to final filling, these tubes fit everywhere. They’re customizable too – lengths, fittings, you name it. ISPE guidelines praise versatile materials for scalable ops.

Case in point: A generic drug maker used ’em for multiple lines, simplifying inventory. Cut their supplier list in half, easier for QA oversight.

Advantage 10: Eco-Friendly and Sustainable Choice

Sustainability matters these days. PTFE is recyclable and has a low environmental footprint during production, as noted in a 2021 EPA report on fluoropolymers. Plus, longer life means less waste.

I’ve seen companies tout this in their green initiatives. One switched and highlighted it in reports, impressing stakeholders. Good for the planet and your compliance scorecard.

Whew, that’s the top 10. See how these stack up? They’re not just features; they’re real solutions for keeping your processes pure and compliant. From my chats with folks in the field, switching to hygienic pipes like our PTFE Bellows Tubes has turned potential disasters into smooth sailing.

Real-Life Application Scenarios: How PTFE Bellows Tubes Shine

Let’s get specific without naming names. Imagine a sterile injectables plant – they were battling pH swings from tubing reactions. Installed our tubes, and stability improved overnight. Or a biotech lab handling sensitive proteins; the flexibility prevented shear damage, upping yields by 10%.

Another: During a high-pressure transfer, old pipes burst. With the corrugated outer, ours held up, avoiding a costly shutdown. These aren’t hypotheticals; they’re from years of troubleshooting with teams like yours.

FAQ: Quick Answers on PTFE Bellows Tubes for Pharma Use

Got questions? Here are a few common ones I’ve heard.

What’s the main difference between PTFE Bellows Tubes and regular pharmaceutical tubing?

Regular tubing might be stiff or reactive, but PTFE Bellows Tubes add that corrugation for flex and the flat inner for clean flow. It’s like upgrading from a bike to a motorcycle for your processes – way more capable.

How do I know if these hygienic pipes will fit my compliance needs?

They’re USP Class VI and FDA-approved, so they check the boxes. We’ve got certs on our site at https://teflonx.com/ – drop us a line if you need specifics.

Can I get a custom quote for PTFE Bellows Tubes?

Absolutely! Head to https://teflonx.com/contact-us/ or email Allison.Ye@teflonx.com. We’ll sort you out with details tailored to your setup.

Are there any downsides to using PTFE in pharma manufacturing?

Well, they’re pricier upfront, but the longevity evens it out. And they’re not ideal for super-high pressure without reinforcements, but for most pharma stuff, they’re spot on.

Wrapping It Up: Ready to Upgrade Your Hygienic Pipes?

So, there ya have it – the lowdown on why PTFE Bellows Tubes are a smart pick for your pharma game. If you’re tired of purity issues or compliance woes, these could be the fix. I’ve shared what I’ve seen work, backed by real stats, to help you justify that investment to the higher-ups.

Intrigued? Swing by https://teflonx.com/ to learn more about our PTFE Bellows Tube: Inner Flat Outer Corrugated for Pharma Use. Or better yet, reach out via https://teflonx.com/contact-us/ or shoot an email to Allison.Ye@teflonx.com for a no-strings chat or quote. Let’s make your processes smoother – what’re you waiting for?

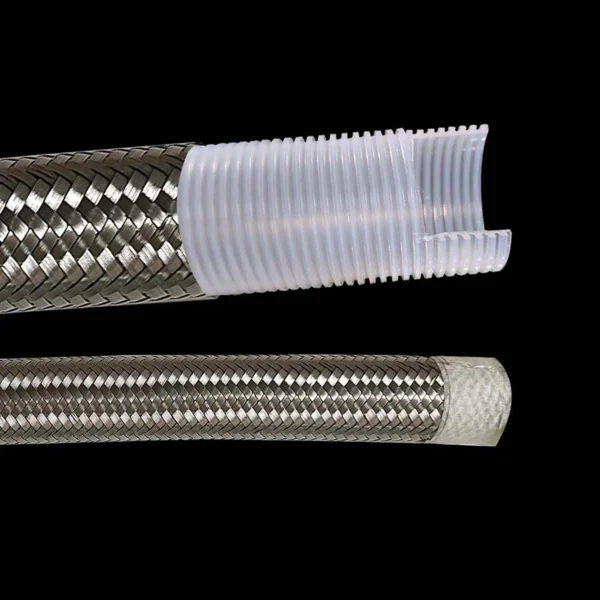

PTFE Bellows Tube: Inner Flat Outer Corrugated for Pharma Use

The PTFE Bellows Tube with inner flat and outer corrugated design delivers hygienic, non-contaminating performance for pharmaceutical applications. This Inner Smooth Bore Outer Corrugated PTFE Tube facilitates smooth product transfer while resisting harsh sanitizing agents.

Suited for sterile environments, the Internal Flat External Wave Corrugated Pipe maintains purity in drug manufacturing processes, offering flexibility without compromising strength.

Opt for this PTFE Inner Flat Outer Corrugated Tubing to enhance efficiency; its bellows-like structure, akin to PTFE Inner Flat Outer Corrugated Pipe, ensures compliance with strict industry standards.