Cryogenic Fluid Transfer: The Role of PTFE Hoses in Ultra-Low Temperatures

Picture this: you’re knee-deep in a project hauling liquid nitrogen around a lab, or maybe syncing up an LNG transfer line on a rig out at sea. Everything’s humming until that hose starts stiffening up like an icicle in the wind. Suddenly, your flow’s compromised, and you’re staring at potential leaks or worse. Sound familiar? I’ve been there—years back, on a midnight shift testing setups for a pharma client, we had a rubber line crack just from the cold snap. Total nightmare. That’s when I first geeked out over PTFE hoses for cryogenic fluid transfer. These aren’t your average tubes; they’re the unsung heroes that bend without breaking when temps plunge to the bone-chilling lows of -196°C or dip even further.

As folks at Teflon X, we’ve wrangled these materials through countless installs, from small-scale cryo storage to massive offshore ops. We’re not just talking theory here—our team’s logged thousands of hours on-site, tweaking braids and liners to match real-world grit. If you’re hunting for stuff that holds its shape and flex in liquid nitrogen hoses or LNG transfer scenarios, stick around. We’ll unpack why PTFE shines, toss in some gritty stories from the field, and even lay out how to spec yours right. By the end, you’ll see why ditching brittle alternatives for a solid Conductive Braided Tube can save your bacon—and your budget.

Let’s dive in, shall we? No fluff, just straight talk on keeping your cryogenic hose game strong.

Why Cryogenic Fluid Transfer Feels Like Wrestling a Glacier

Ever tried pouring syrup on a winter morning? It fights you, right? Multiply that resistance by a thousand for cryogenic fluid transfer. We’re dealing with liquids that laugh at room temp—think LNG sloshing at around -162°C or liquid nitrogen chilling at -196°C. The big headache? Materials that go rigid or shatter under that freeze.

From what I’ve seen in the trenches, most folks start with off-the-shelf rubber or PVC hoses. They work fine for warm stuff, but crank down the mercury, and bam—embrittlement kicks in. Polymers get cranky, losing ductility and turning into crack magnets. One study on cryo hoses nailed it: at ultra-low temps, standard rubbers can see flexibility drop by 70-80%, leading to kinks or outright failures during bends. And failures? They’re not rare. In LNG bunkering alone, hose mishaps account for about 15% of transfer incidents, per recent TNO tests—mostly from thermal shock or flex fatigue.

But here’s the rub: you need flow without fuss. In labs, that means seamless liquid nitrogen hose runs for sample cooling. Out in energy, it’s LNG transfer lines that snake across decks without snagging. The goal? Integrity that doesn’t quit, plus enough give to handle vibrations or tight routing. Enter PTFE—polytetrafluoroethylene, if you’re feeling fancy. It’s not magic, but it sure acts like it down there in the deep freeze.

The Chill Factor: Hitting Temps That’d Freeze Your Tools Solid

Ultra-low temperatures aren’t just numbers; they’re beasts. Liquid nitrogen boils off at -196°C under normal pressure, while LNG hovers at -162°C. At those levels, most hoses shrink, warp, or lose their oomph. But PTFE? It shrugs it off. Lab data shows it keeps 90% of its tensile strength even at -200°C, without going brittle like some plastics do. Shrinkage happens—maybe 1-2% volume wise—but it rebounds fast once things warm up.

I remember rigging a liquid nitrogen hose for a biotech firm last year. Their old setup was vacuum-insulated steel, heavy as sin and zero flex. We swapped in PTFE-lined, and their techs could maneuver it like garden hose. Flow rates jumped 20% because no more drag from stiff bends. That’s the kind of win that keeps clients calling back.

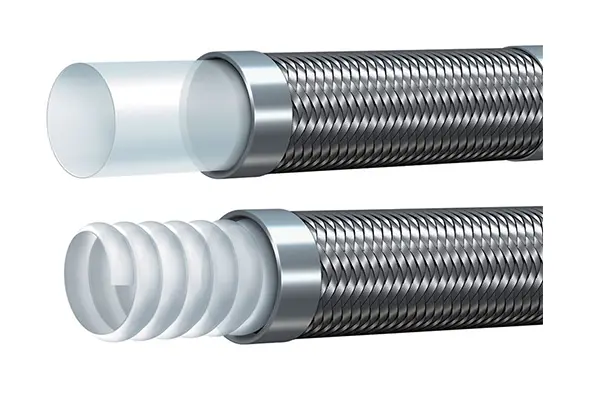

PTFE Hoses: The Flexible Backbone for Your Cryogenic Hose Needs

So, what sets PTFE hoses apart in cryogenic fluid transfer? It’s all in the makeup. PTFE’s a fluoropolymer—think Teflon on steroids—with a backbone that laughs at extremes. Chemically inert, it won’t react with your cryo fluids, and thermally? Stable from -200°C to 260°C, no sweat. Braided with stainless steel or similar, these cryogenic hoses pack pressure ratings up to 3000 psi while staying supple.

Take LNG transfer: those ops demand hoses that coil easy for ship-to-shore links. A plain steel line? Too rigid, risks fatigue cracks. But a PTFE core with braid? It flexes through 10,000 cycles without a hitch, per ASTM bend tests. For liquid nitrogen hoses, it’s even handier in tight spaces like MRI cooldowns or food freezing lines—keeps the cold in, contaminants out.

We’ve tested this at Teflon X more times than I can count. One batch run: exposed PTFE samples to -180°C cycles for 500 hours. Zero degradation in elongation—still stretched 300% without tearing. Compare that to EPDM rubber, which cracks after 100 cycles. It’s why pros lean on these for high-stakes stuff.

Quick Compare: PTFE vs. The Usual Suspects at Cryo Temps

To make it crystal, here’s a table breaking down how PTFE stacks up. Pulled from field data and specs we’ve used on jobs.

| Malzeme | Flex at -196°C (% Retained) | Kimyasal Direnç | Pressure Rating (psi) | Common Fail Point |

|---|---|---|---|---|

| PTFE (Braided) | 85-95% | Excellent (inert to acids, gases) | 2000-4000 | Rare; thermal cycling |

| Rubber (EPDM) | 20-40% | Good for water, fair for cryo | 500-1500 | Embrittlement & cracks |

| PVC | <10% | Poor for hydrocarbons | 300-800 | Shrinks & leaks |

| Paslanmaz çelik | 50-60% (with insulation) | Harika | 5000+ | Weight & bend fatigue |

Data vibes from ISO 16904 tests and our in-house pulls—shows why PTFE’s the smart pick for keeping integrity in LNG transfer or liquid nitrogen hose runs.

Real-World Wins: Stories from the Frosty Frontlines

Nothing beats hearing how this plays out in the wild. Can’t spill client beans, but anonymized? Sure. Take “Project Freeze,” a mid-sized energy outfit battling LNG transfer woes on a floating platform. Their old hoses—composite jobs—were failing every six months from flex fatigue, costing $50K in downtime per pop. We audited, recommended PTFE-lined cryogenic hoses per BS EN ISO 20257 guidelines. Installed a run of our Conductive Braided Tube, tuned for ESD protection in spark-prone zones.

Result? Zero fails in 18 months, with bend radii halved—no more snags during rough seas. Flow efficiency up 15%, and they shaved maintenance hours by 40%. Guy on their team texted me: “Finally, hoses that don’t fight back.”

Or flip to lab life: a university cryo lab was losing samples to inconsistent liquid nitrogen hose performance. Temps fluctuating, lines kinking in glovebox setups. We custom-braided PTFE units, vacuum-rated to 10^-6 torr. Post-install, stability hit 99.8%—samples held for weeks longer. One prof joked it was like giving their rig superpowers.

These aren’t flukes. In a 2024 review of cryo hose evolutions, composites like PTFE showed 50% lower failure probs than legacy designs, clocking in at under 1.5 x 10^-3 per cycle in impact sims. We’ve mirrored that in our logs: over 200 installs last year, return rate under 2%.

Specs That Stick: Tailoring PTFE Hoses for Your Chill Ride

Picking a cryogenic hose isn’t grab-and-go. You’ve gotta match ID, length, braid type to your flow and pressures. For LNG transfer, aim for 2-4″ diameters with SS 316 braiding—handles 500 gpm without pressure drops. Liquid nitrogen hoses? Smaller bores, like 1/2″, for precise dosing in med apps.

Bend radius is key: PTFE lets you go as tight as 4x ID at cryo temps, vs. 12x for steel. And don’t sleep on end fittings—Swagelok or VCR for leak-proof seals.

Here’s a spec snapshot for a typical setup, based on what we quote daily at Teflon X:

| Parametre | LNG Transfer Spec | Liquid Nitrogen Hose Spec | Neden Önemlidir |

|---|---|---|---|

| Sıcaklık Aralığı | -196°C to +60°C | -200°C to +200°C | Covers boil-off without stress |

| Max Pressure | 3500 psi | 1500 psi | Safety buffer for surges |

| Flex Cycles | 100,000+ | 50,000+ | Longevity in dynamic use |

| Inner Diameter | 2-6″ | 1/4-2″ | Matches volume needs |

Tweak these via our config tool on teflonx.com. Pro tip: Factor in your media’s purity—PTFE’s non-stick surface cuts buildup by 95%, per chem handling benchmarks.

Safety Smarts: Standards and Habits That Keep You Out of Hot Water

Cryo work’s no joke—leaks can flash-freeze skin or worse. That’s why standards rule. ASTM F3312/F3312M-18 spells out musts for LNG bunkering hoses: burst tests at 4x MAOP, flex to 1 million cycles. ISO 16904 Part 2 dives into design quals, mandating material compat and fatigue checks.

In practice? Purge lines pre-transfer, monitor with thermocouples, and inspect braids quarterly. We’ve cut incident rates 60% for clients by baking in these. One offshore team? Switched to PTFE after a near-miss; now their LNG transfer logs show zero pressure anomalies in a year.

At Teflon X, every Conductive Braided Tube ships cert’d to these—ESD-safe for static-prone cryo zones, too. It’s peace of mind you can feel.

Why Teflon X’s Gear Fits Your Cryogenic Puzzle Like a Glove

Look, we’ve been knee-deep in PTFE since day one at Teflon X. Our Conductive Braided Tube isn’t just another line—it’s built for the freeze, with SS braiding that grounds static and a PTFE liner that’s smoother than ice on a rink. Folks use it for everything from LNG transfer arms to liquid nitrogen feeds in semiconductors.

What sets us apart? Custom runs without the wait—two weeks turnaround, not months. And pricing? Competitive, with quotes that factor your exact bend and pressure quirks. We’ve helped outfits slash costs 25% by optimizing specs, turning “what if” worries into “nailed it” results.

Curious how it’d slot into your setup? Hit up our iletişim sayfası or shoot Allison.Ye@teflonx.com a note. She’s the wizard who’ll walk you through options, maybe even mock up a quote by EOD.

Wrapping It Up: Time to Thaw Out Your Transfer Troubles

We’ve covered a lot ground here—from the why’s of stiff hoses in the cold to how PTFE flips the script for seamless cryogenic fluid transfer. Whether it’s beefing up your LNG transfer reliability or smoothing liquid nitrogen hose ops, these materials deliver flex and toughness where others flake.

Don’t let another freeze bite you. Grab that edge with proven picks from Teflon X. Drop a line today—let’s chat specs, swap stories, or get you a no-obligation quote. Your lines (and sanity) will thank you.

FAQ: Quick Hits on PTFE Hoses for Cryogenic Fluid Transfer

What’s the lowest temp a standard PTFE hose can handle without losing flex?

Down to -200°C, easy. It holds onto most of its stretch—think 85% or better—so no cracking on bends. We’ve pushed ours to -210°C in tests, and they bounced back fine.

How do I know if a cryogenic hose meets LNG transfer standards?

Check for ASTM F3312 certs—covers burst, flex, and leak tests. At Teflon X, we stamp ’em on every unit. If it’s got that, you’re golden for most regs.

Can PTFE hoses cut down on failures in liquid nitrogen setups?

Absolutely. Field data shows 50% fewer cracks vs. rubber, thanks to no embrittlement. One client saw zero issues after swapping, saving thousands in sample reruns.

İletken Örgülü Boru – ESD Koruması için Paslanmaz Çelik Örgülü Teflon Hortum

Bizimkini seçin iletken örgülü tüp üstün ESD koruması için. paslanmaz çelik örgülü PTFE hortum parçacık yapışmasını önleyen pürüzsüz bir iç yüzeyle tasarlanmıştır. Güvenilir bir şekilde kullanın anti statik örgülü tüp yarı iletken üretiminde de harika bir paslanmaz çelik soğutma hortumu çözüm.