Introduction

Polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon®, is a high-performance fluoropolymer with unique material characteristics that make it indispensable across industries. But what exactly makes PTFE stand out? How do its PTFE properties translate to real-world PTFE industrial uses? This article explores 10 critical properties of PTFE material and their applications, supported by authoritative data and practical insights.

1. Exceptional Thermal Stability

PTFE Temperature Range and Heat Resistance

PTFE operates reliably in temperatures ranging from -200°C to +260°C (-328°F to +500°F)[1], making it ideal for extreme environments.

Industrial Applications:

- Aerospace: Insulation for wiring and gaskets in jet engines.

- Chemical Processing: Lining for reactors handling exothermic reactions.

| Property | PTFE | Nylon | PVC |

|---|---|---|---|

| Max Continuous Temp (°C) | 260 | 120 | 60 |

| Thermal Conductivity | 0.25 W/m·K | 0.25 W/m·K | 0.15 W/m·K |

2. Superior Chemical Resistance

PTFE is inert to almost all chemicals, including acids, alkalis, and solvents[2].

Key Applications:

- Pharmaceuticals: Seals in drug manufacturing equipment.

- Oil & Gas: Coatings for pipelines exposed to corrosive fluids.

3. Low Friction Coefficient

With a friction coefficient of 0.05–0.10[3], PTFE reduces wear in moving parts.

Industrial Uses:

- Automotive: Bearings and piston rings.

- Food Processing: Non-stick conveyor belts.

4. Electrical Insulation

PTFE’s dielectric strength (60 kV/mm) ensures safety in high-voltage applications[4].

Applications:

- Electronics: Insulating films for circuit boards.

- Power Generation: Coating for high-voltage cables.

5. Non-Stick Surface

The smooth surface of PTFE material prevents adhesion, critical for:

- Cookware: Non-stick frying pans.

- Textiles: Release layers in industrial laminators.

6. UV and Weather Resistance

PTFE withstands prolonged UV exposure without degradation[5], ideal for:

- Construction: Roofing membranes in stadiums.

- Solar Energy: Protective films for photovoltaic panels.

7. Biocompatibility

PTFE is FDA-approved for medical use, applied in:

- Healthcare: Vascular grafts and surgical sutures.

- Dental: Coatings for orthodontic wires.

8. Low Permeability

PTFE’s dense structure minimizes gas/liquid penetration, used in:

- Semiconductors: Seals for vacuum chambers.

- Packaging: Barriers for moisture-sensitive products.

9. High Purity

PTFE generates minimal particulates, essential for:

- Pharmaceuticals: Cleanroom equipment linings.

- Electronics: Wafer-handling components.

10. Durability in Harsh Environments

Combining thermal, chemical, and mechanical resilience, PTFE is used in:

- Defense: Seals for submarines and missile systems.

- Mining: Liners for abrasive slurry transport.

FAQs: Addressing Common Queries

Q: Is PTFE safe for food contact?

A: Yes, FDA-compliant PTFE is inert and non-toxic when undegraded[2].

Q: Can PTFE be recycled?

A: Specialty programs exist, but recycling is challenging due to its stability[5].

Conclusion and Recommendations

PTFE’s material characteristics—from its broad PTFE temperature range to chemical inertness—make it a cornerstone of modern engineering. For industries seeking reliability in extreme conditions, PTFE industrial uses offer unmatched performance.

Action Step: Evaluate component wear, chemical exposure, or thermal stress in your operations—PTFE could be the solution.

References

[1] ASTM International Standards for Polymers (2023)

[2] Chemical Safety Facts: PTFE in Medical Applications (2024)

[3] Tribology Journal: Friction Coefficients of Polymers (2023)

[4] IEEE Electrical Insulation Standards (2024)

[5] Environmental Science & Technology: PTFE Recycling Challenges (2023)

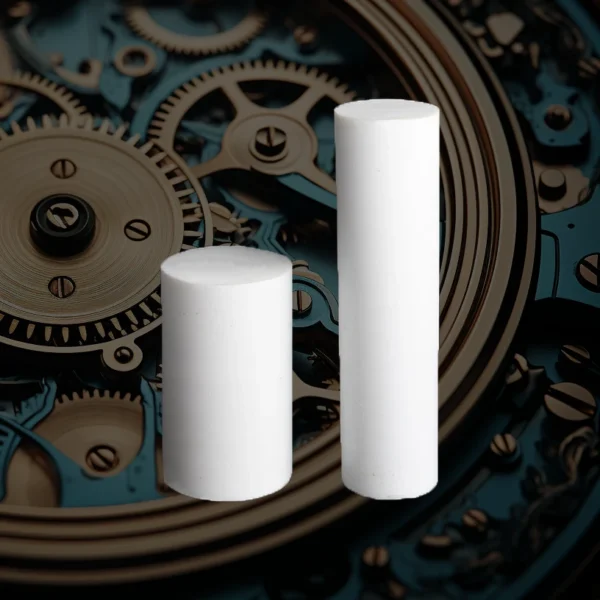

Custom PTFE Rod for Oil & Gas – High Lubrication Bar

PTFE rods are designed for oil and gas applications, offering high lubrication and temperature resistance. These custom teflon round bars improve efficiency in petrochemical setups. Tailored to your specifications.