Jika Anda mencari-cari informasi tentang tabung berbelit-belit PTFE karena atasan Anda baru saja menjatuhkan sebuah proyek di meja Anda dan Anda bertanya-tanya, "Tunggu, barang apa ini?", Anda berada di tempat yang tepat. Saya telah berkecimpung di dunia Teflon X selama bertahun-tahun, mengutak-atik selang dan tabung untuk semua jenis pertunjukan industri yang liar. Anggap saja saya sebagai teman yang memperbaiki kebocoran di pabrik pada jam 2 pagi. Kami akan menjelaskannya secara sederhana-tidak ada jargon yang rumit, hanya pembicaraan langsung tentang apa itu Teflon X, mengapa Teflon X sangat bagus, dan bagaimana Teflon X dapat menyelamatkan bangunan Anda berikutnya. Pada akhirnya, Anda akan merasa seperti sedang mengobrol tentang spesifikasi dengan pemasok sambil minum kopi.

Apa itu Tabung Berbelit-belit PTFE?

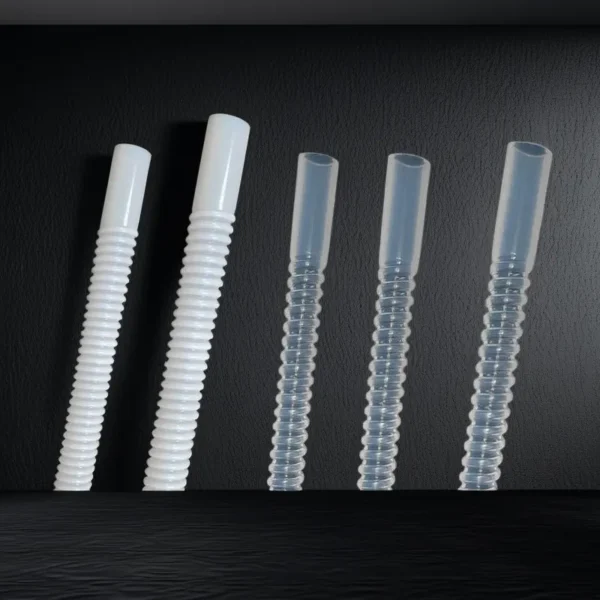

Baiklah, mari kita mulai dengan pertanyaan besar: apa itu tabung berbelit-belit PTFE? Bayangkan sebuah tabung biasa, tetapi dengan tonjolan bergelombang yang membentang di sepanjang bagian luarnya, seperti karton bergelombang dalam kotak pengiriman. Gelombang itu? Itulah yang membuatnya sangat lentur tanpa tertekuk atau retak di bawah tekanan. PTFE adalah singkatan dari polytetrafluoroethylene-ya, seteguk, tetapi orang-orang menyebutnya Teflon hampir setiap hari. Ini adalah bahan licin yang Anda lihat di wajan antilengket, tetapi diperkuat untuk pekerjaan berat.

Pada intinya, tabung ini menangani bahan kimia yang berbahaya, perubahan suhu yang liar, dan ruang sempit di mana tabung lurus akan patah seperti ranting. Kami telah mengirimkan berton-ton Teflon X ke tempat-tempat seperti pabrik mobil dan laboratorium kimia, dan sejujurnya, ini adalah pengubah permainan saat Anda merutekan jalur melalui mesin yang berputar-putar. Jika Anda seorang pemula dalam pengadaan atau insinyur yang sedang membuat sketsa prototipe pertama Anda, dengan mengetahui hal-hal dasar ini, Anda tidak akan terbakar karena lembar spesifikasi yang buruk.

Dasar-Dasar Tabung PTFE

Menyelami lebih dalam tentang dasar-dasar tabung PTFE, mulailah dari sini: terbuat dari fluoropolimer yang pada dasarnya tidak dapat dihancurkan oleh sebagian besar asam, basa, dan pelarut. Tidak main-main-jatuhkan saja ke dalam asam baterai atau minyak rem, dan itu akan langsung hancur. Satu hal yang selalu mengejutkan orang adalah bagaimana plastik ini tetap licin di dalam; koefisien gesekannya adalah yang terendah dari semua plastik di luar sana, sekitar 0,05 hingga 0,10. Itu berarti cairan dapat mengalir tanpa terseret atau menumpuk.

Dari segi suhu, bahan ini tahan terhadap suhu ekstrem-dari -400°F hingga 500°F tanpa meleleh atau rapuh. Kami telah menguji batch di Teflon X yang bertahan dalam pengujian freezer hingga -328 ° F, langsung dari standar ASTM. Ukuran? Anda bisa mendapatkannya mulai dari ID 1/16 inci yang kecil untuk gadget medis hingga yang berukuran 2 inci untuk saluran bahan bakar. Dan warna? Sebagian besar berwarna putih alami, tetapi kami mewarnainya agar mudah dikenali dalam pengaturan yang ramai.

Oh, dan fasilitas listrik-ini adalah juara untuk isolasi, dengan konstanta dielektrik 2,1 pada rentang frekuensi yang sangat besar. Jika proyek Anda melibatkan kabel atau sensor, ini membuat semuanya bebas dari gangguan.

Pengenalan Tabung Berbelit-belit

Sekarang, untuk pengenalan singkat tentang tabung yang berbelit-belit: tonjolan-tonjolan itu bukan hanya untuk pajangan. Mereka memungkinkan tabung melentur hingga 10 kali lebih banyak daripada versi yang mulus, dengan radius tikungan seketat 1-2 inci, tergantung ukurannya. Bayangkan melilitkannya di sekitar blok mesin atau ke dalam lengan robot-tabung yang halus akan melawan Anda setiap inci, tetapi yang berbelit-belit? Ini mengalir seperti air.

Kami pertama kali mulai menggunakannya dengan berat pada Teflon X untuk transfer bahan bakar pada gigi off-road, di mana getaran akan mengunyah garis-garis yang lebih lurus. Ada juga pilihannya: dinding ringan untuk penghematan berat atau berat untuk ketahanan ekstra terhadap benturan. Versi anti-statis mematikan percikan api di zona ledakan, yang menyelamatkan waktu henti klien ketika pengaturan lama mereka terus melengkung.

Mengapa Harus Berbelit-belit? Pertarungan Halus vs Bergelombang

Pernahkah Anda memperdebatkan cara yang mulus versus cara yang berbelit-belit dalam sebuah pertemuan tim? Saya pernah, banyak. Smooth sangat bagus untuk tembakan lurus dengan aliran maksimal, tetapi convoluted menang dalam hal kelenturan dan pemasangan di tempat yang aneh. Berikut ini adalah tabel singkat untuk menyelesaikannya-tidak ada bulu halus, hanya perbedaan yang kami lihat dalam instalasi nyata.

| Fitur | Tabung PTFE Lubang Halus | Tabung PTFE yang berbelit-belit |

|---|---|---|

| Fleksibilitas | Layak, tetapi lebih mudah tertekuk di tikungan | Cara menekuk lebih tinggi 180° tanpa tekanan |

| Tikungan Radius | Biasanya 4-6x ID | Serendah 1-2x ID untuk perutean yang ketat |

| Laju Aliran | Bagian dalam yang lebih halus, lebih sedikit turbulensi | Sedikit tonjolan dapat menambah hambatan kecil, tetapi dapat diabaikan untuk sebagian besar |

| Peringkat Tekanan | Semburan yang lebih tinggi (hingga 5.000 psi) | Padat hingga 3.000 psi, tergantung pada dinding |

| Kemudahan Berat/Pemasangan | Lebih ringan, tetapi lebih keras dalam lekukan | Sedikit lebih besar, tetapi menginstal 2x lebih cepat di jalur yang kompleks |

| Biaya | Lebih murah di muka | 20-30% lebih banyak, tetapi bertahan lebih lama saat bergerak |

Hal ini kami dapatkan dari pertukaran langsung yang telah kami lakukan-seperti membuang jalur yang mulus untuk jalur konveyor yang berbelit-belit, sehingga memangkas waktu pemasangan hingga setengahnya. Jika pengaturan Anda memiliki gerakan atau sudut, bergelombang adalah pilihan Anda.

Hal-hal yang sulit: Properti Utama yang Membuatnya Menarik

Mari kita mengobrol tentang properti tanpa kesan buku teks. Ketahanan terhadap bahan kimia? Menduduki peringkat teratas-menolak 98% korosif yang diketahui, sesuai panduan Teflon lama DuPont. Kami memiliki batch yang berada dalam asam sulfat 30% selama berminggu-minggu selama tes kualifikasi; keluar mengkilap seperti baru.

Daya tahan adalah hal yang lain. Pompa luar ruangan yang tahan UV dan tahan terhadap cuaca - pikirkan pompa luar ruangan di padang pasir. Dan gesekan yang rendah itu? Menjaga partikel agar tidak menempel, yang merupakan emas untuk ruang bersih atau jalur makanan. Pasar juga berkembang pesat; adegan tabung PTFE akan mencapai $1.85 miliar pada tahun 2025, tumbuh sebesar 5.2% per tahun hingga tahun 2034. Mengapa? Semua orang mengejar peralatan yang andal dan minim perawatan.

Dari waktu saya di Teflon X, hal yang paling penting adalah umur panjang. Seorang klien dalam peralatan ag menjalankan jalur yang berbelit-belit selama 5 tahun berturut-turut di bawah kelenturan yang konstan-tanpa penggantian. Mengalahkan selang karet yang rusak dalam hitungan bulan.

Di Mana Ia Bersinar: Aplikasi dan Cerita Singkat

Jadi, di mana letaknya di dunia Anda? Laboratorium untuk reagen yang mengular tanpa kebocoran. Mobil untuk saluran rem atau bahan bakar yang meliuk-liuk dengan sasis. Bahkan pemandu kateter untuk keperluan medis yang harus melengkung dengan lembut.

Ambil contoh mesin industri: kami Tabung Bahan Bakar Bergelombang dibuat khusus untuk itu, menangani aliran diesel dalam mesin yang bergetar tanpa hambatan. Memiliki fleksibilitas ekstra untuk perutean di sekitar manifold panas, dan kami telah menyesuaikan panjangnya untuk armada forklift.

Inilah kemenangan yang tidak disebutkan namanya: Sebuah pabrikan Midwest kehilangan waktu berjam-jam setiap minggu karena selang bahan bakar yang tertekuk pada bot perakitan. Beralih ke pengaturan PTFE kami yang berbelit-belit, waktu henti turun 70%, dan mereka menghemat $15 ribu per tahun untuk perbaikan. Tidak ada nama, tetapi gambar robot bersenandung dengan lancar alih-alih berhenti.

Ada lagi? Pabrik farmasi membutuhkan tabung anti-statis untuk transfer pelarut. Rute yang berbelit-belit membiarkan mereka melewati panel yang ketat; tidak ada insiden sejak pemasangan. Ini bukan hipotetis-langsung dari catatan kami di Teflon X.

Memilih Pasangan Anda: Kiat Pembeli yang Tidak Suka Berbohong

Baiklah, Anda sudah setuju-sekarang apa? Mulailah dengan kebutuhan Anda: Berapa suhu maksimalnya? Paparan bahan kimia? Persyaratan tikungan? Untuk dasar-dasarnya, carilah produk yang sesuai dengan ASTM D3295, yang mencakup keredupan dan toleransi pipa. Ketebalan dinding sangat penting-0,03 inci untuk tugas ringan, hingga 0,1 untuk tekanan.

Ukuran yang tepat: ID untuk aliran, OD untuk pemasangan di atas duri. Uji sampel jika Anda bisa; kami mengirimkannya gratis dari teflonx.com. Kiat pro: Faktor dalam penutup stainless yang dikepang dengan fitting akan meningkatkan penanganan tekanan.

Anggaran? Tingkat pemula yang berbelit-belit mulai dari $2/ft, tetapi harga premium untuk custom mencapai $10. Timbanglah dengan masa pakai-berbuah dengan cepat.

Menjaganya Agar Tetap Sah: Standar dan Kepercayaan

Kualitas bukanlah lelucon. Tetap berpegang pada ASTM D1710 untuk spesifikasi ekstrusi-memastikan resin yang konsisten. Di Teflon X, kami mencapai Tipe I, Grade 4 sesuai dengan tolok ukur Teflon DuPont, jadi Anda tahu itu bukan tiruan.

Kami juga memiliki sertifikat ISO, yang diaudit setiap tahun. Percayalah, berhemat di sini akan berujung pada kegagalan yang sangat merugikan.

PERTANYAAN YANG SERING DIAJUKAN: Pertanyaan-pertanyaan Anda Terjawab

T: Bagaimana pipa berbelit-belit menangani tekanan tinggi dibandingkan dengan pipa biasa?

J: Batas aman sekitar 3.000 psi, tetapi tambahkan jalinan dan Anda bisa mencapai 10.000 psi. Kami telah menguji tekanan kami hingga 1,5x lipatnya tanpa masalah.

T: Dapatkah saya menggunakan PTFE yang berbelit-belit untuk makanan atau barang medis?

J: Ya, jika bersertifikat USP Kelas VI. Produk kami memenuhi persyaratan FDA untuk kontak tidak langsung-bagus untuk produk susu atau pilot farmasi.

T: Berapa umur simpan pada tabung ini?

J: Tidak terbatas jika disimpan di tempat sejuk dan kering. Kami telah menarik stok berusia 10 tahun dan kinerjanya seperti hari pertama.

Dengar, jika ini memicu beberapa ide tetapi Anda masih menggaruk-garuk kepala Anda tentang spesifikasi atau penawaran, hubungi tim di Teflon X. Kirimkan pesan ke Allison.Ye@teflonx.com atau mampir ke halaman kontak-kami akan menyortir sampel atau mengobrol tentang pengaturan Anda. Jangan biarkan tabung yang buruk menggagalkan proyek Anda; raih keunggulan itu hari ini dan jaga agar semuanya tetap lancar. Apa langkah pertama Anda?

Selang Bahan Bakar Bergelombang PTFE untuk Aplikasi Dirgantara

Selang bahan bakar bergelombang PTFE memastikan pemindahan bahan bakar yang andal dalam sistem kedirgantaraan. Desain selang bahan bakar Teflon-nya tahan terhadap suhu ekstrem (-80°C hingga +250°C) dan bahan bakar korosif. Tabung bahan bakar bergelombang yang diperkuat baja tahan karat yang fleksibel meminimalkan getaran dan memastikan ketahanan dalam lingkungan bertekanan tinggi. Ideal untuk sistem injeksi bahan bakar presisi dengan perawatan rendah.