Introduzione ai filtri a membrana in PTFE

L'acqua è l'essenza della vita, ma garantirne la purezza per il consumo, l'uso industriale o la sicurezza ambientale continua a essere una sfida globale. Filtri a membrana in PTFE, noti per il loro PTFE idrofobico proprietà, sono emerse come una pietra angolare nell'avanzato filtrazione dell'acqua sistemi. Questi filtri, realizzati in politetrafluoroetilene (PTFE), offrono durata, resistenza chimica ed efficienza di filtrazione senza pari. A Teflon Xsiamo specializzati nella fornitura di filtri a membrana in PTFE di alta qualità, studiati appositamente per diverse applicazioni di trattamento delle acque.

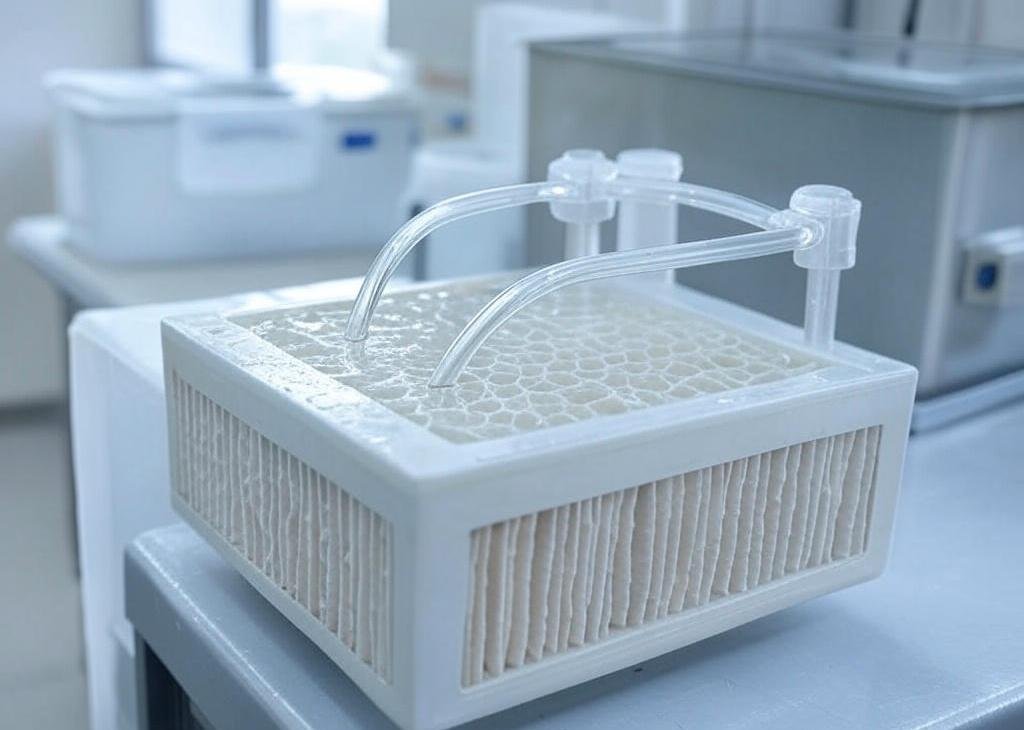

Cosa sono i filtri a membrana in PTFE?

I filtri a membrana in PTFE sono membrane microporose realizzate in politetrafluoroetilene, un fluoropolimero sintetico rinomato per le sue proprietà antiaderenti e idrofobiche. PTFE idrofobico La natura garantisce che le molecole d'acqua vengano respinte, consentendo il passaggio solo di gas o liquidi specifici in condizioni controllate. Questa caratteristica unica rende i filtri in PTFE ideali per applicazioni che richiedono elevata purezza e resistenza a sostanze chimiche aggressive.

Proprietà principali dei filtri a membrana in PTFE

| Proprietà | Descrizione |

|---|---|

| Idrofobicità | Respinge l'acqua, rendendolo ideale per la filtrazione di gas e la filtrazione selettiva di liquidi. |

| Resistenza chimica | Resiste ad acidi, basi e solventi, garantendo durevolezza in ambienti difficili. |

| Alta porosità | Offre portate ed efficienza di filtrazione eccellenti. |

| Stabilità termica | Funziona efficacemente a temperature comprese tra -100°C e 260°C. |

| Basso attrito | Riduce l'intasamento e aumenta la durata del filtro. |

Queste proprietà, unite alle dimensioni precise dei pori (in genere da 0,1 a 5,0 micron), rendono i filtri a membrana in PTFE versatili per i sistemi di trattamento delle acque.

Applicazioni dei filtri a membrana in PTFE nel trattamento delle acque

I filtri a membrana in PTFE sono ampiamente utilizzati nei sistemi di trattamento delle acque in diversi settori, dalla depurazione delle acque municipali alla produzione farmaceutica. Di seguito, ne illustriamo le principali applicazioni, supportate da dati ed esempi concreti.

1. Trattamento delle acque reflue industriali

I processi industriali generano spesso acque reflue contenenti metalli pesanti, oli e contaminanti organici. I filtri a membrana in PTFE eccellono nella separazione di questi inquinanti grazie alla loro resistenza chimica e alle proprietà idrofobiche. Secondo un rapporto del 2023 dell' Agenzia per la protezione dell'ambiente (EPA), le tecnologie di filtrazione a membrana, tra cui il PTFE, hanno ridotto i livelli di contaminanti negli effluenti industriali fino al 95% negli impianti conformi.

A Teflon Xi nostri filtri in PTFE sono progettati per gestire il trattamento delle acque reflue ad alta capacità, garantendo la conformità alle severe normative ambientali.

2. Purificazione dell'acqua potabile

Garantire acqua potabile sicura è una priorità globale. I filtri a membrana in PTFE vengono utilizzati nei sistemi di prefiltrazione e ultrafiltrazione a osmosi inversa (RO) per rimuovere batteri, virus e particolato. Uno studio pubblicato su Ricerca sull'acqua (2022) hanno scoperto che i filtri a base di PTFE hanno raggiunto un tasso di rimozione del 99,9% per i contaminanti microbici nei sistemi idrici municipali.

I nostri filtri Teflon X sono progettati per soddisfare NSF/ANSI 53 standard per la sicurezza dell'acqua potabile, rendendoli una scelta affidabile per i comuni e i produttori di acqua in bottiglia.

3. Trattamento delle acque farmaceutiche

L'industria farmaceutica richiede acqua ultrapura per la produzione di farmaci e la pulizia delle apparecchiature. I filtri a membrana in PTFE sono ideali per la produzione di acqua per preparazioni iniettabili (WFI) grazie alla loro capacità di rimuovere endotossine e microrganismi. Farmacopea degli Stati Uniti (USP) specifica la filtrazione a membrana come fase critica nella produzione di WFI e i filtri in PTFE sono spesso consigliati per la loro affidabilità.

4. Desalinizzazione

Gli impianti di desalinizzazione si basano su tecnologie a membrana per convertire l'acqua di mare in acqua potabile. I filtri a membrana in PTFE fungono da prefiltri nei sistemi a osmosi inversa (RO), proteggendo le membrane a valle dall'incrostazione. Un rapporto del 2024 del... Associazione Internazionale per la Desalinizzazione (IDA) è stato osservato che la prefiltrazione avanzata della membrana ha aumentato la durata della membrana RO di 20%, riducendo i costi operativi.

Vantaggi dell'utilizzo di filtri a membrana in PTFE

La scelta di filtri a membrana in PTFE per il trattamento dell'acqua offre diversi vantaggi:

- Efficienza di filtrazione superiore: Le dimensioni dei pori fino a 0,1 micron garantiscono la rimozione di particelle fini e microrganismi.

- Lunga durata:La stabilità chimica e termica riduce la frequenza di sostituzione, abbassando i costi.

- Versatilità: Adatto sia per applicazioni di filtrazione di liquidi che di gas.

- Ecologico:I filtri in PTFE possono essere puliti e riutilizzati, riducendo gli sprechi.

A Teflon X, miglioriamo questi vantaggi offrendo filtri a membrana in PTFE personalizzati, pensati su misura per le vostre specifiche esigenze di trattamento dell'acqua. Contattaci per scoprire come le nostre soluzioni possono ottimizzare i tuoi processi di filtrazione.

Confronto tra i filtri a membrana in PTFE e altri materiali

Per evidenziare la superiorità del PTFE, lo confrontiamo con altri materiali filtranti comuni:

| Materiale | Idrofobicità | Resistenza chimica | Costo | Applicazioni |

|---|---|---|---|---|

| PTFE | Alto | Eccellente | Alto | Trattamento delle acque, prodotti farmaceutici |

| Polipropilene | Moderare | Bene | Basso | Filtrazione generale, ambienti meno difficili |

| Nylon | Basso | Moderare | Medio | Filtrazione biologica |

| Ceramica | Basso | Eccellente | Molto alto | Filtrazione industriale per impieghi gravosi |

La natura idrofobica e la resistenza chimica del PTFE lo rendono la scelta migliore per le applicazioni più impegnative nel trattamento delle acque.

Migliori pratiche per l'utilizzo di filtri a membrana in PTFE

Per massimizzare le prestazioni dei filtri a membrana in PTFE, tenere presente quanto segue:

- Pretrattamento: Utilizzare filtri grossolani per rimuovere le particelle più grandi prima che l'acqua raggiunga la membrana in PTFE.

- Manutenzione ordinaria: Pulire i filtri con solventi compatibili per evitare intasamenti.

- Compatibilità del sistema: Assicurarsi che il sistema di filtrazione supporti i requisiti di temperatura e pressione del PTFE.

Il nostro team presso Teflon X fornisce guide di installazione dettagliate e supporto tecnico per garantire prestazioni ottimali del filtro.

Domande frequenti sui filtri a membrana in PTFE

1. Cosa rende i filtri a membrana in PTFE idrofobici?

La struttura molecolare del PTFE respinge l'acqua, consentendo il passaggio solo di gas o liquidi specifici. Questo PTFE idrofobico proprietà ideale per la filtrazione selettiva nei sistemi di trattamento delle acque.

2. I filtri a membrana in PTFE possono essere riutilizzati?

Sì, i filtri in PTFE possono essere puliti e riutilizzati più volte, a seconda dell'applicazione e del metodo di pulizia. Consultare Teflon X per protocolli di pulizia specifici.

3. I filtri a membrana in PTFE sono sicuri per l'acqua potabile?

Assolutamente sì. I filtri in PTFE soddisfano rigorosi standard di sicurezza, come NSF/ANSI 53, garantendo la sicurezza per le applicazioni con acqua potabile.

Conclusione: Migliora il trattamento dell'acqua con Teflon X

Filtri a membrana in PTFE si stanno trasformando filtrazione dell'acqua offrendo efficienza, durata e versatilità senza pari. Che si tratti di trattare acque reflue industriali, purificare acqua potabile o produrre acqua di grado farmaceutico, i filtri in PTFE di Teflon X fornire prestazioni affidabili.

Non scendere a compromessi sulla qualità dell'acqua. Contatta Teflon X oggi Per discutere delle vostre esigenze di filtrazione e richiedere un preventivo. Lasciate che vi aiutiamo a ottenere un'acqua più pulita e sicura con le nostre soluzioni avanzate con membrana in PTFE.

Riferimenti:

- Agenzia per la protezione dell'ambiente (EPA), 2023. Rapporto sul trattamento delle acque reflue industriali.

- Ricerca sull'acqua, 2022. Rimozione microbica nei sistemi idrici municipali.

- Farmacopea degli Stati Uniti (USP), Standard per l'acqua per preparazioni iniettabili.

- Associazione Internazionale per la Desalinizzazione (IDA), 2024. Tendenze della tecnologia di desalinizzazione.