Stainless Steel Braided Teflon Hose | High-Performance Fluid Transfer Solutions

Welcome to Teflon X, a premier ptfe tube manufacturer dedicated to engineering superior industrial solutions. Our flagship product, the Stainless Steel Braided Teflon Hose, represents the intersection of durability, flexibility, and chemical inertness. Designed for the most rigorous environments, this ptfe lined hose is essential for industries ranging from aerospace and automotive to chemical processing and pharmaceutical manufacturing.

When your operations demand a conduit that can withstand extreme temperature fluctuations and aggressive corrosive fluids without degrading, standard rubber tubing fails. This is where our polytetrafluoroethylene tubing excels, offering a permanent solution to common fluid transfer challenges.

Advanced Material Composition: The Power of PTFE

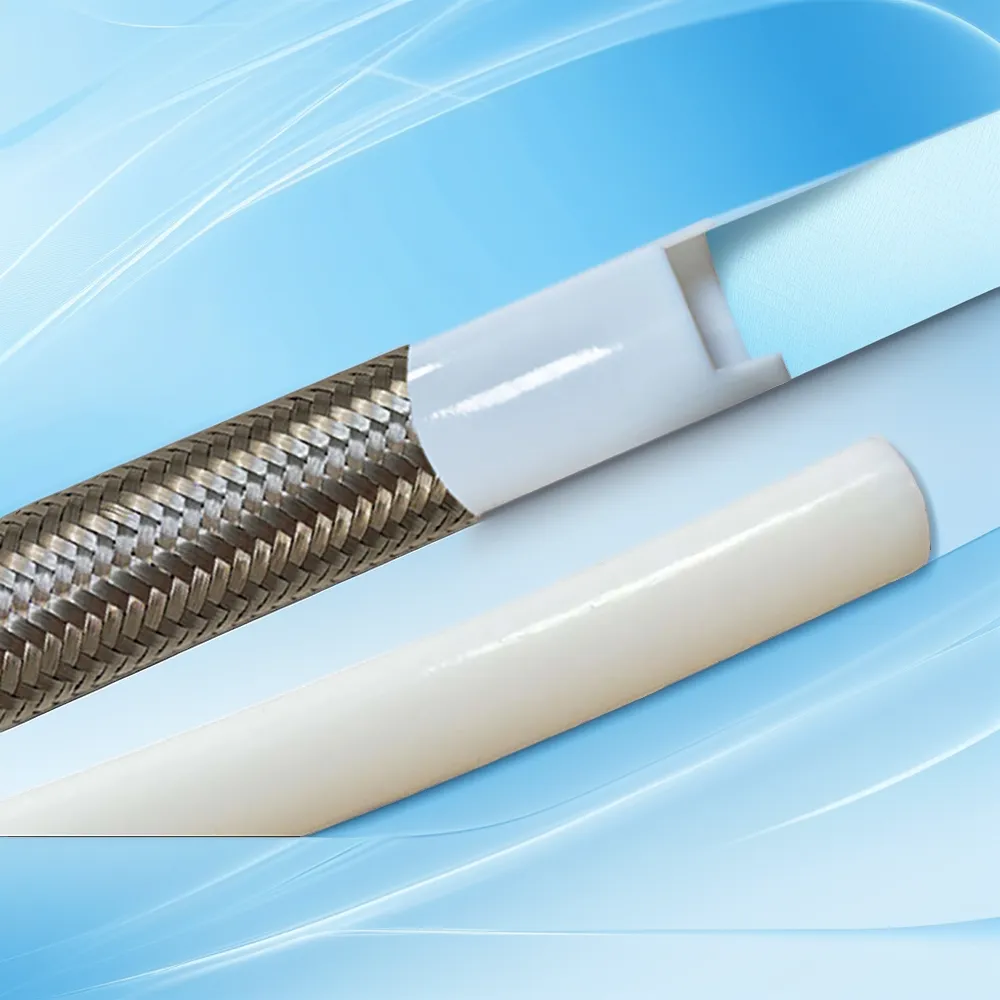

The core of our hose utilizes high-grade ptfe teflon tubing (Polytetrafluoroethylene). This material is renowned in the engineering world for its incredibly low coefficient of friction (0.04) and “non-stick” properties. This ensures that viscous fluids, chemicals, and steam flow smoothly through the ptfe tube with minimal pressure drop and zero contamination build-up.

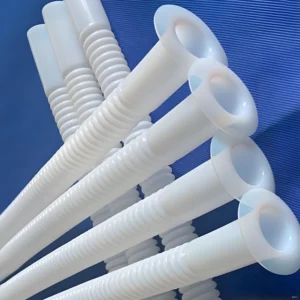

Unlike traditional materials that become brittle over time, our flexible ptfe tubing maintains its structural integrity across a massive temperature spectrum. As detailed in our specifications, this product effectively operates from freezing cryogenic lows of -70°C up to scorching highs of +260°C. This thermal stability makes it the ideal choice for heat exchangers, cooling lines, and steam transfer.

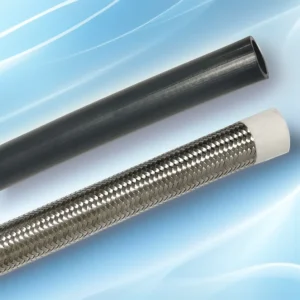

Reinforced Durability: Stainless Steel Braiding

A bare ptfe tube is excellent for chemical resistance, but for high-pressure industrial applications, it requires reinforcement. Our stainless steel braided teflon hose features a robust outer layer of stainless steel wire mesh. This braiding serves three critical functions:

- Pressure Resistance: It significantly increases the burst pressure rating of the hose, allowing it to handle pressures up to 1.6 MPa (depending on diameter) safely.

- Protection: It acts as an armor against external abrasion, cuts, and environmental wear.

- Kink Resistance: The braid limits the bend radius, preventing the inner teflon tubing from kinking and cutting off flow, while still maintaining the characteristics of flexible ptfe tubing.

Product Specifications

At Teflon X, we believe in transparency and precision. Below are the specific technical parameters for this model of our Teflon Braided Pipe.

| Brand | Teflon X |

| Material | Ptfe / polytetrafluoroethylene |

| ID of Tube (Inner Diameter) | 6.3 ~ 25.4mm |

| Temperature Range | -70 ~ +260°C |

| Features | Corrosion resistance, high and low temperature resistance, high pressure resistance, soft |

Why Industries Choose Teflon X Tubing

1. Chemical Inertness:

Our ptfe lined hose is virtually impervious to almost all chemicals, acids, alkalis, and solvents. This makes it safe for transporting aggressive media that would dissolve standard hoses.

2. Vibration Absorption:

In automotive and compressor applications, vibration can cause metal pipes to fatigue and crack. The flexible nature of our stainless steel braided teflon hose absorbs these vibrations, extending the life of your entire system.

3. Longevity and Cleanliness:

The non-aging properties of polytetrafluoroethylene tubing mean you replace hoses less frequently. Furthermore, because the material imparts no taste or smell and resists bacterial growth, it is suitable for strict hygiene standards.

Customization and Manufacturing Excellence

As a leading ptfe tube manufacturer, we control the quality from raw material to finished product. The ID range specified (6.3mm to 25.4mm) covers the most common industrial requirements, offering a “soft” yet durable installation experience. Whether you need a single replacement hose or a bulk order for OEM production, Teflon X delivers consistency you can trust.

Get in Touch

Are you ready to optimize your systems with high-quality teflon tubing? Our engineering team is ready to assist you with selection and technical support.

Email: allison.ye@teflonx.com

Website: https://teflonx.com/

Contact Page: Contact Us for a Quote

Reviews

There are no reviews yet.